A method for forming a gate dielectric layer on the surface of graphene and preparing a transistor

A graphene surface, gate dielectric layer technology, applied in coating, metal material coating process, semiconductor/solid state device manufacturing, etc. problem, to achieve the effect of excellent performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

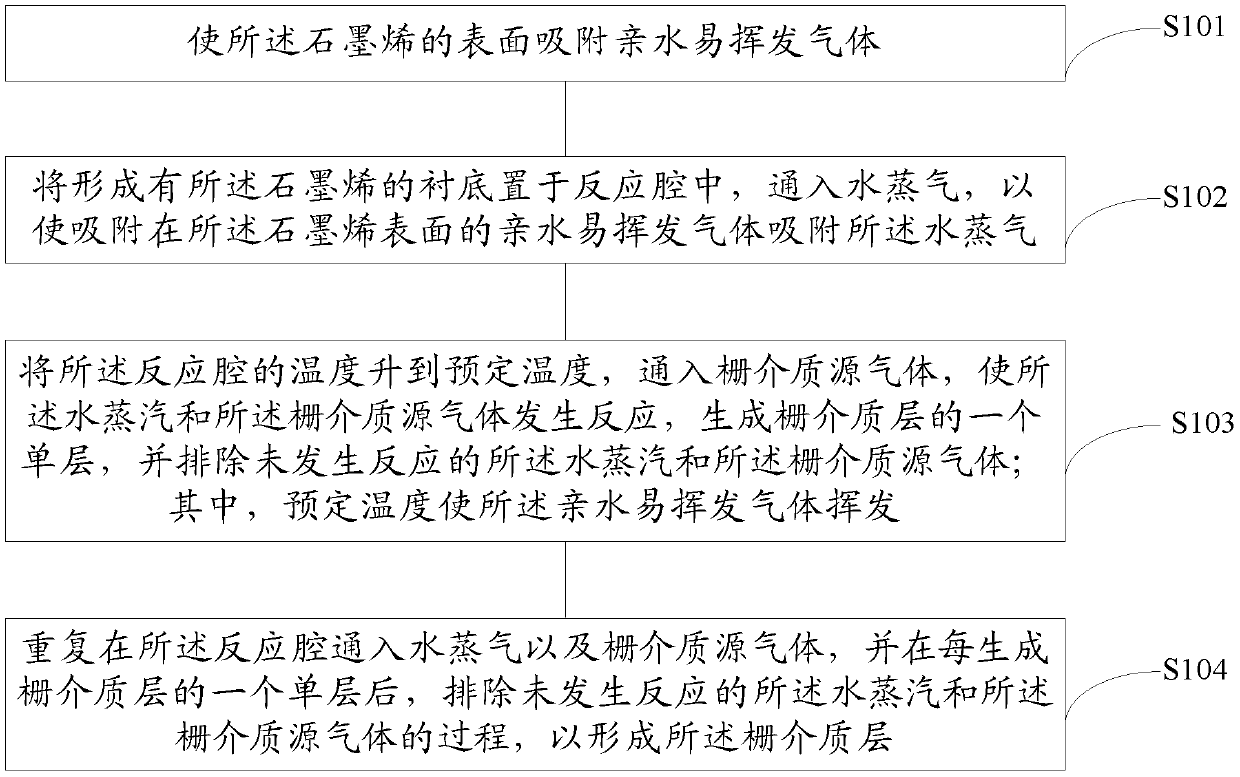

[0074] Embodiment 1: A gate dielectric layer 60 of aluminum oxide is formed on the surface of graphene 20, such as Figure 4 As shown, it specifically includes the following steps:

[0075] S201. Using a micromechanical exfoliation method to peel off the graphene 20 from the graphite, and form the graphene on a 300 nm silicon oxide substrate.

[0076] S202 , placing the substrate 10 formed with the graphene 20 in step S201 in an 85% ammonia atmosphere to adsorb ammonia molecules.

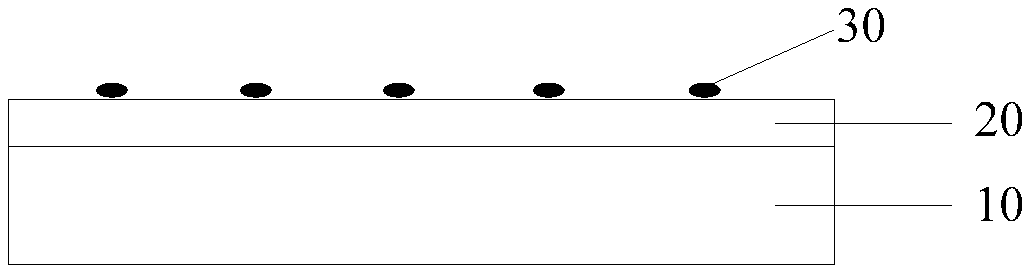

[0077] S203, placing the graphene 20 adsorbed ammonia in S202 in the ALD reaction chamber, and passing water vapor 40 under room temperature conditions, so that the surface of the graphene 20 adsorbs water molecules.

[0078]S204. Raise the temperature of the ALD reaction chamber to 300° C., and introduce trimethylaluminum vapor, and the trimethylaluminum vapor reacts with the water molecules adsorbed on the surface of the graphene 20 to form a single layer 50 of the gate dielectric layer 60 of alu...

Embodiment 2

[0081] Embodiment 2: Form a gate dielectric layer 60 of hafnium dioxide on the surface of graphene 20, such as Figure 5 As shown, it specifically includes the following steps:

[0082] S301. Form graphene 20 by chemical vapor deposition, and transfer graphene 20 to a quartz surface by using PMMA (Polymethylmethacrylate).

[0083] S302, placing the substrate 10 formed with the graphene 20 in step S301 in a 90% hydrogen chloride environment to absorb hydrogen chloride molecules.

[0084] S303, placing the graphene 20 adsorbed with hydrogen chloride in step 302 in the ALD reaction chamber, and passing water vapor 40 at room temperature, and the surface of the graphene 20 adsorbs water molecules.

[0085] S304. Raise the temperature of the ALD reaction chamber to 300° C., and introduce hafnium tetrachloride vapor, and the hafnium tetrachloride vapor reacts with the water molecules adsorbed on the surface of graphene 20 to form a monolayer of hafnium dioxide gate dielectric layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com