Method used for smooth and steady preparation of 2-methoxypropandioic acid ethyl methyl ester

A technology of methyl ethyl methoxymalonate and methyl methoxy acetate, which is applied in the field of preparation of sulfonamide intermediates, can solve problems such as danger, temperature rise, unfavorable safety management of production workshops, etc., and achieve improvement Yield, reduce the intensity of the reaction, reduce the effect of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

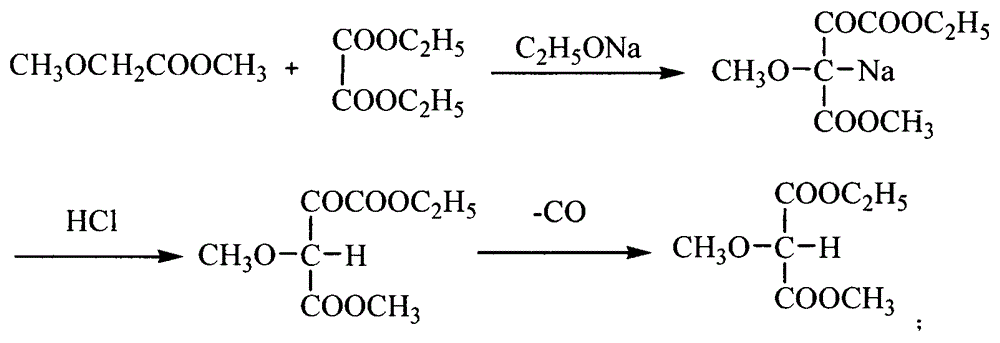

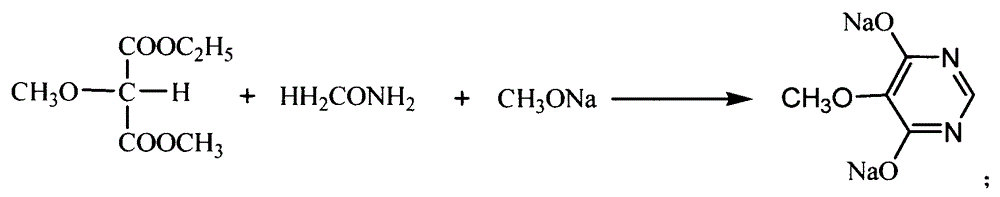

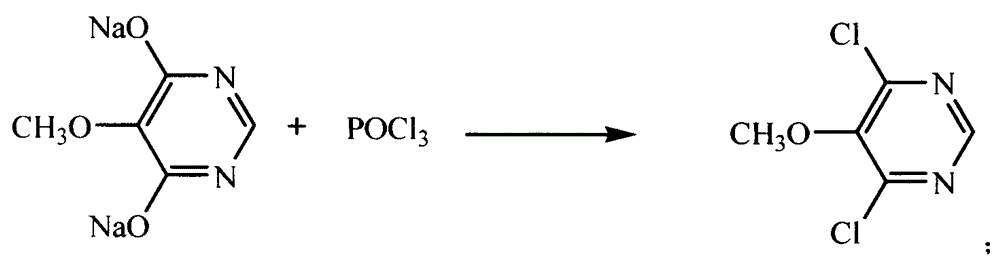

Method used

Image

Examples

Embodiment 1

[0033] This example provides a kind of method for stably preparing methyl ethyl methoxymalonate, and specific feeding ratio is as shown in Table 1:

[0034] Table 1 Reaction raw materials and their feeding ratio

[0035]

[0036] The specific operation process is as follows:

[0037] (a) 175kg of methyl methoxyacetate and 150kg of diethyl oxalate are put into a pre-dried mixed ester pot, stirred and mixed, and cooled to below 10°C, and put into a pre-dried Kjeldahl reaction kettle;

[0038] (b) Disperse 130kg of solid sodium ethylate in 150kg of diethyl oxalate, drop it into the above-mentioned Kjeldahl reaction kettle at a rate of 10 drops / second (the dropping time is controlled within 1 to 2 hours), and control the reaction liquid The temperature is between 50 and 60°C, and the reaction is kept for 4 hours;

[0039] (c) Add 280L trichlorethylene in advance in the dilution pot and cool it to below 20°C, then pour the reaction pressure in the Kjeldahl reaction pot into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com