Method for separating and purifying yam polysaccharide

A yam polysaccharide, separation and purification technology, applied in the food field, can solve the problem of insufficient structural analysis and research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

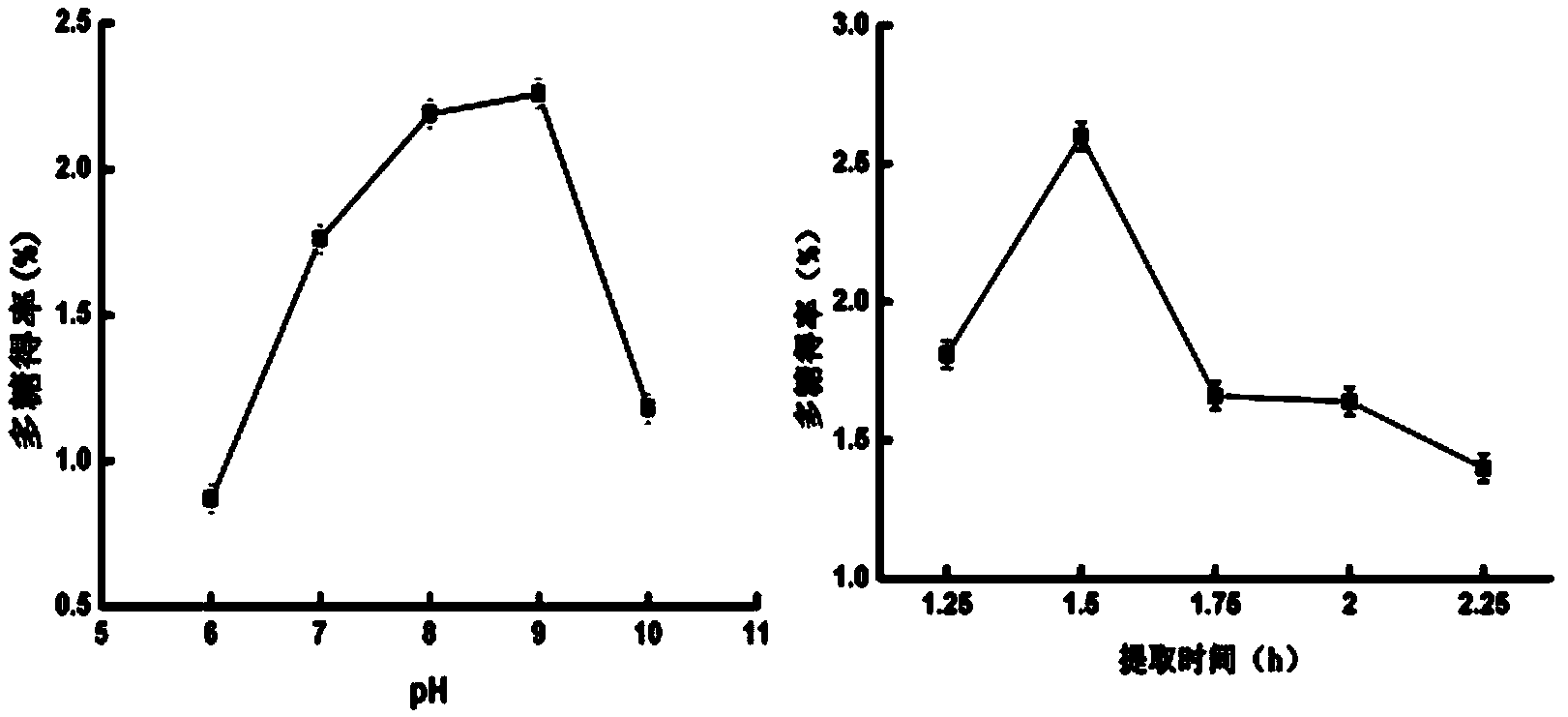

[0034] Example 1. Extraction of yam polysaccharide and four influencing factors

[0035] Wash the fresh yam, slice it (as thin as possible), add a color-protecting agent (1.5% citric acid, 0.75% sodium sulfite, 1.5% sodium chloride) to protect the color for 30 minutes, and dry it in an oven at 50°C (to prevent browning). Turn the sheets every two hours to prevent uneven heating during the drying process. The dried yam slices were pulverized with a pulverizer, and 10 g of pulverized yam powder was weighed and put into a conical flask, and extracted in a water bath to obtain an extract. After the extract was taken out, centrifuge at 8000r / min for 15min, take the supernatant, and measure the volume. After diluting the supernatant by 300 times, take 1mL and add them to the test tubes respectively, add 1mL of 5% phenol and 5mL of concentrated sulfuric acid, shake and mix well, bathe in water at 45°C for 30min, measure the absorbance at the wavelength of 490nm, and use the same vol...

Embodiment 2

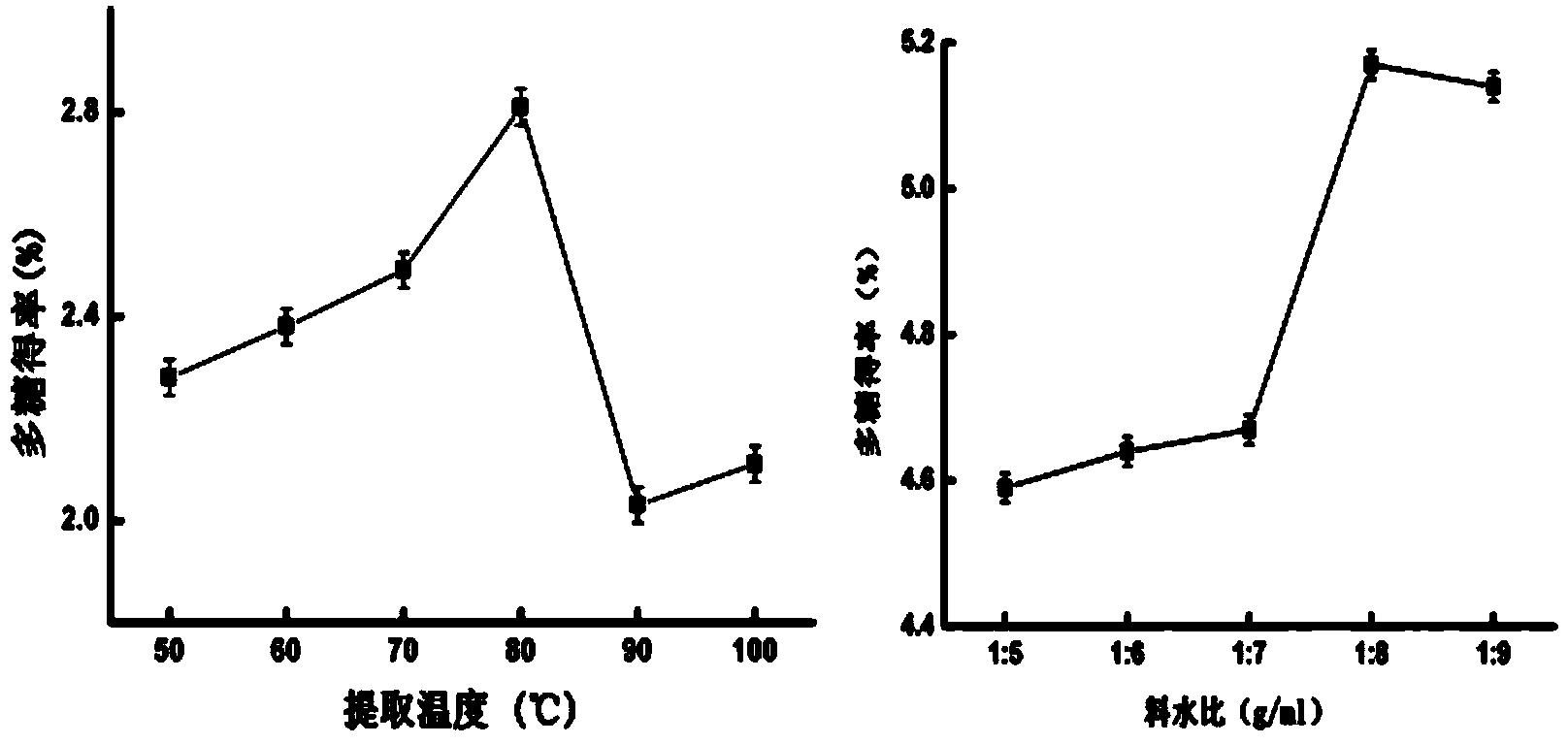

[0039] Example 2. Response surface optimization extraction condition analysis

[0040] On the basis of single factor analysis, the extraction conditions were optimized according to Design Expert7.1.6 software. The experimental factors and level design are shown in Table 1.

[0041] Table 1 Factors and levels of Box-Behnken experiment

[0042]

[0043]

[0044] Taking A, B, C, and D as independent variables, and polysaccharide yield as the response value, a total of 29 groups of experiments were carried out, and the experimental scheme is shown in Table 2

[0045] Table 2 Box-Behnken experimental design and results

[0046]

[0047] Through Design Expert 7.1.6 software, quadratic polynomial regression fitting was performed on the experimental data in Table 2, and the obtained quadratic polynomial regression equation was:

[0048] R1=+5.56-0.31*A-0.44*B-0.97*C+0.32*D-0.19*A*B-0.25*A*C-0.23*A*D-0.090*B*C-0.14*B*D -0.44*C*D-1.55*A 2 -1.01*B 2 -1.84*C 2 -0.44*D 2 ...

Embodiment 3

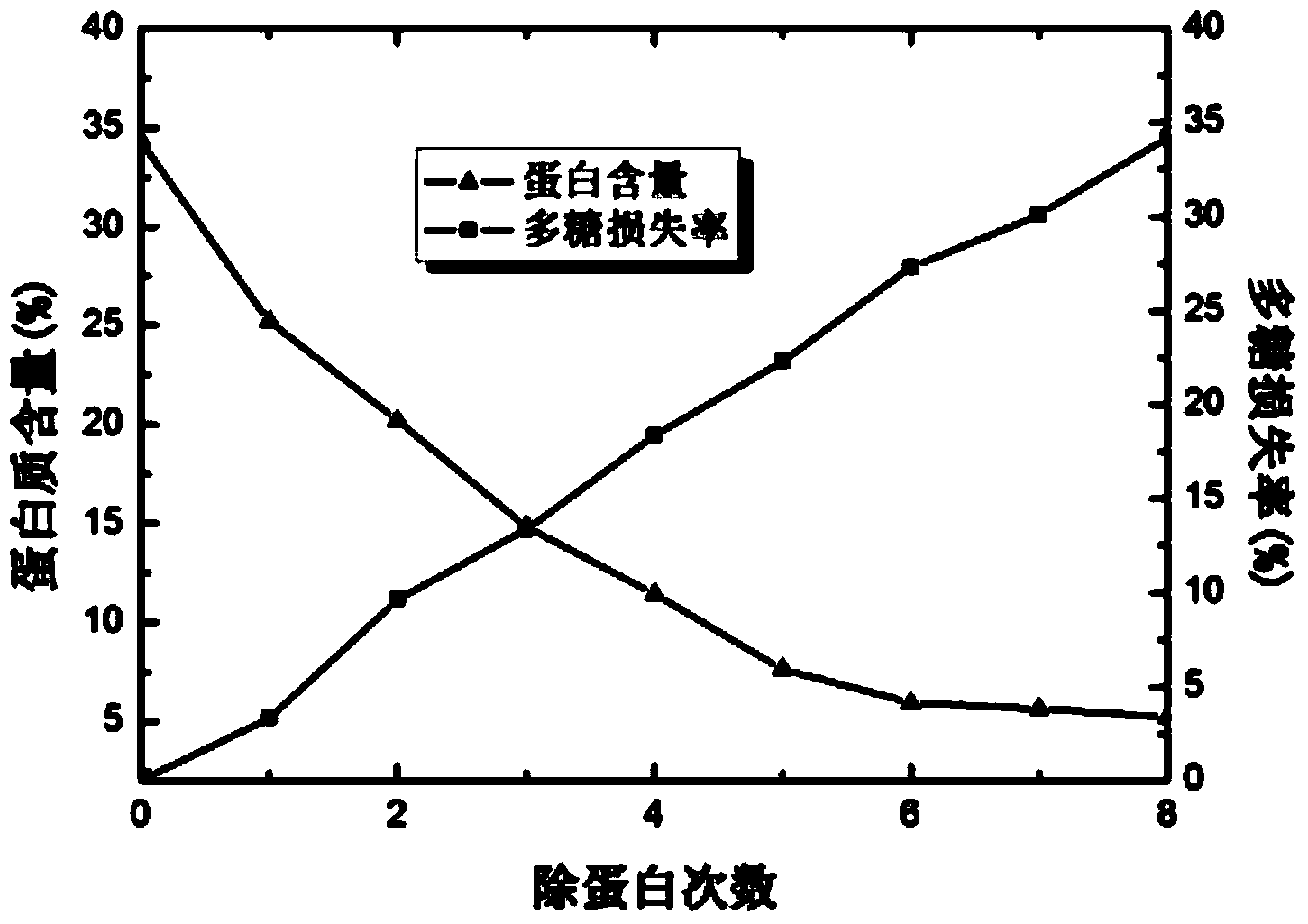

[0054] Embodiment 3. the purification of yam polysaccharide

[0055] The yam polysaccharide was further optimized to improve its purity. The primary task of purifying polysaccharides in the present invention is to remove proteins. The Sevage method is used in the experiment. This method is relatively mild, but it cannot achieve the goal at one time. best times. The purification of crude polysaccharide tentatively adopts high-speed countercurrent chromatography for crude separation of polysaccharide, and explores the relevant chromatographic conditions. Residual small molecule compounds were subsequently removed by dialysis. Purified by Sephadex G-100 chromatographic column to obtain pure polysaccharide, and finally carry out the identification of polysaccharide purity and the determination of molecular weight.

[0056] The result is as follows: Figure 2A It shows the relationship between protein content and polysaccharide loss rate by Sevage method. It can be seen from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com