Production method of tiny amorphous silicon thin film solar cell

A solar cell and amorphous silicon thin film technology, which is applied in the field of solar energy applications, can solve the problems of high attenuation, low conversion efficiency, and obstacles to the large-scale application of amorphous silicon thin film solar cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

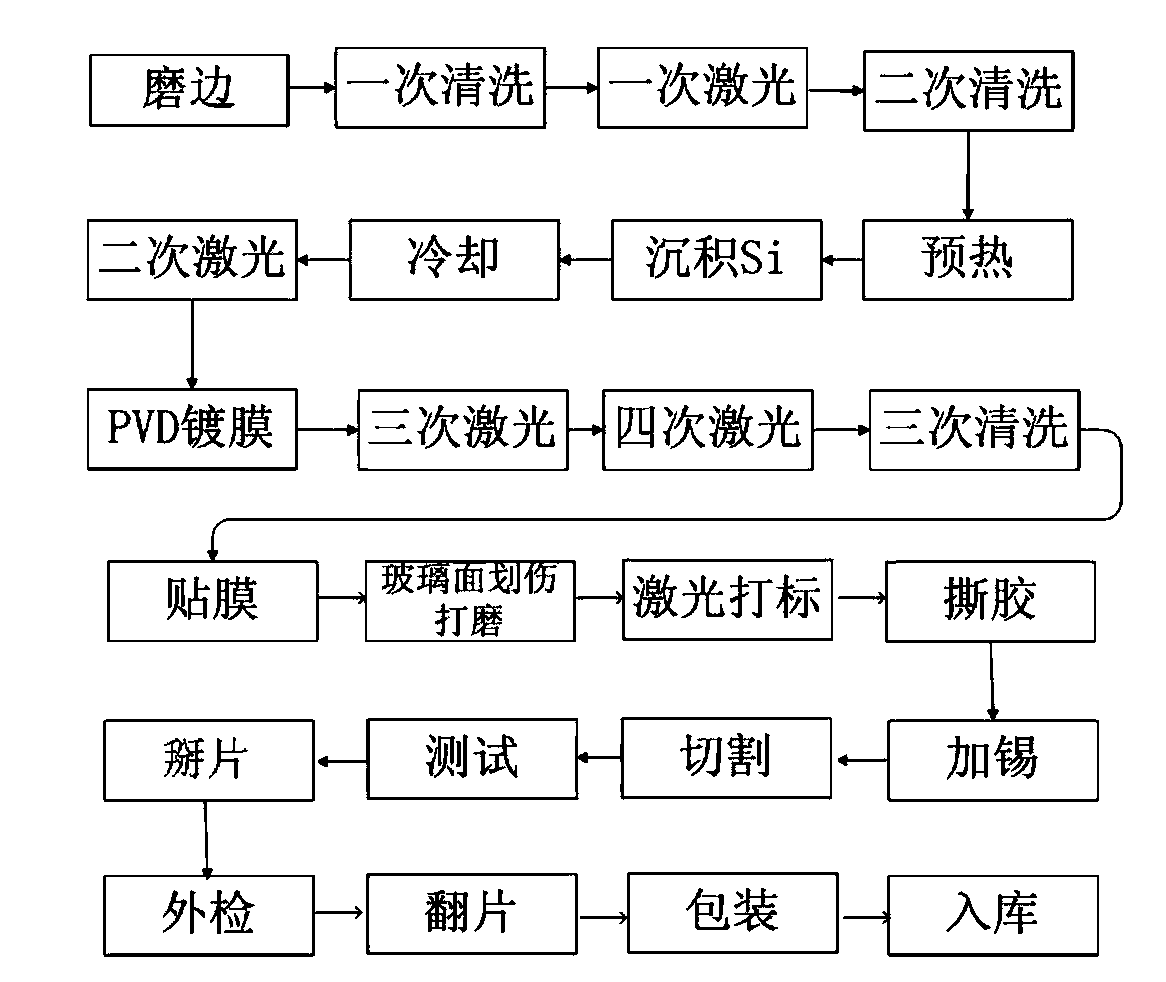

[0037] The present embodiment relates to a kind of production method of miniature amorphous silicon thin-film solar cells, such as figure 1 As shown, the method includes the following steps:

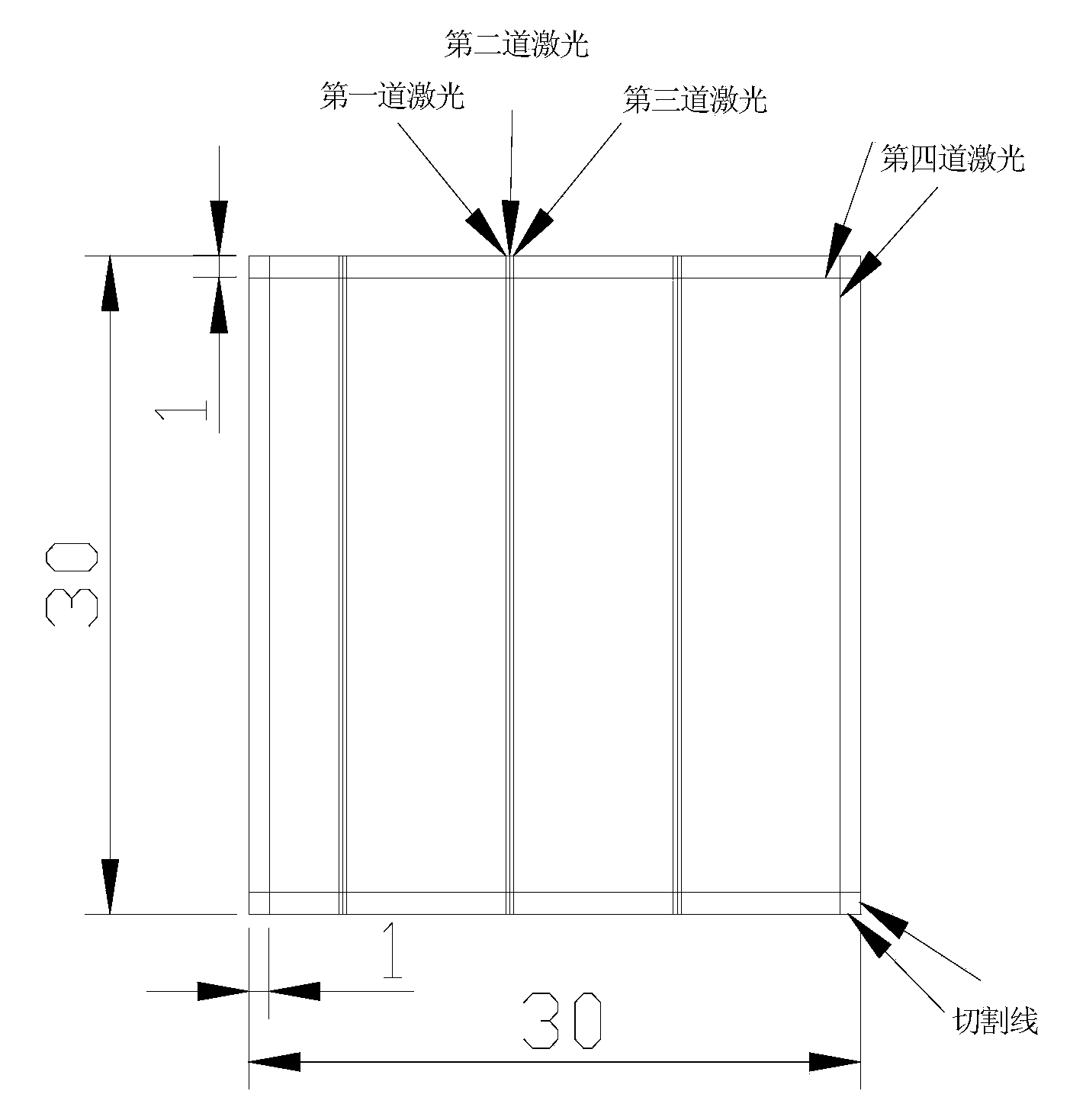

[0038] A. Edge grinding and one-time cleaning of the conductive glass substrate. According to the predetermined line spacing of the production line, a laser scribing is performed on the TCO film layer on it, and the whole board is divided into several pieces, which are used as electrodes of several single cells.

[0039] B. After the second cleaning, preheat, and prepare a single-layer PIN battery film layer by PECVD on the TCO film layer; the details are as follows:

[0040] To prepare the P layer, use B(CH 3 ) 3 、SiH 4 、CH 4 、H 2 Gas, deposition temperature 178℃~182℃, power density 15~19mW / cm2, hydrogen dilution ratio R 23~35, flow ratio of silane to methane 10:1~1.35, deposition pressure 0.8Torr, film thickness 15~ 20nm;

[0041] To prepare layer I, use SiH 4 、H 2 gas, where ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com