Zn element doping mg 2 Si-based thermoelectric materials

An element doping, thermoelectric material technology, applied in the direction of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, etc., can solve the problems of low thermoelectric performance, high price, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

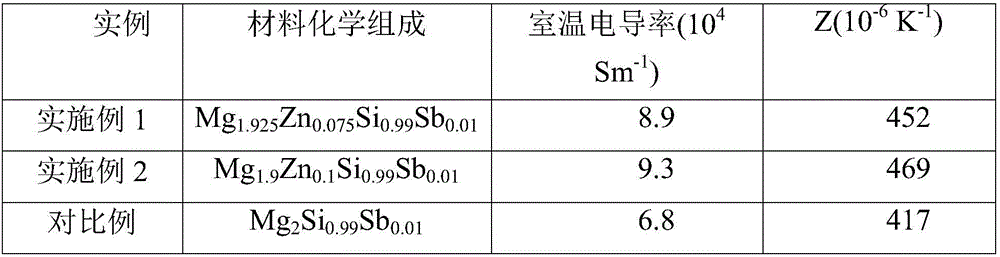

Embodiment 1

[0018] The raw material powder (magnesium, zinc, silicon, antimony) is calculated according to the stoichiometric ratio of Mg 1.925 Zn 0.075 Si 0.99 Sb 0.01 (the Mg element is over 5%, because Mg is easy to volatilize at high temperature, and the Mg content in the final sample is less than that of the chemical formula) After grinding evenly, place it in an alumina open crucible, and cover the raw material with an oxide Boron powder, boron oxide will melt to form a layer of liquid film when the melting temperature is 700℃, covering the raw material sample, preventing the contact between the raw material sample and the outside world, and playing a sealing role, especially preventing the oxidation of Mg and volatile. The raw material sample was smelted in a heat treatment furnace (700°C, 10h), the sample was taken out and ground into powder, and sintered at 80MPa, 1073K vacuum discharge plasma for 15min to obtain 3.75% Zn-doped Mg 1.925 Zn 0.075 Si 0.99 Sb 0.01 block sampl...

Embodiment 2

[0020] The raw material powder (magnesium, zinc, silicon, antimony) is calculated according to the stoichiometric ratio of Mg 1.9 Zn 0.1 Si 0.99 Sb 0.01 (5% of the Mg element is excessive, because Mg will easily volatilize at high temperature, and the Mg content in the final sample will be less than that of the chemical formula) After grinding evenly, place it in an alumina open crucible, and cover the raw material with a Boron oxide powder, when the melting temperature of boron oxide is 700°C, it will melt to form a layer of liquid film, which covers the raw material sample, prevents the contact between the raw material sample and the outside world, and acts as a seal, especially preventing the Mg oxidation and volatilization. The raw material sample was smelted in a heat treatment furnace (700°C, 10h), the sample was taken out and ground into powder, and sintered at 80MPa, 1073K vacuum discharge plasma for 15min to obtain 5% Zn-doped Mg 1.9 Zn 0.1 Si 0.99 Sb 0.01 bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com