Piezoelectric ceramic-polymer composites preparation method and piezoelectric ceramic-polymer composites

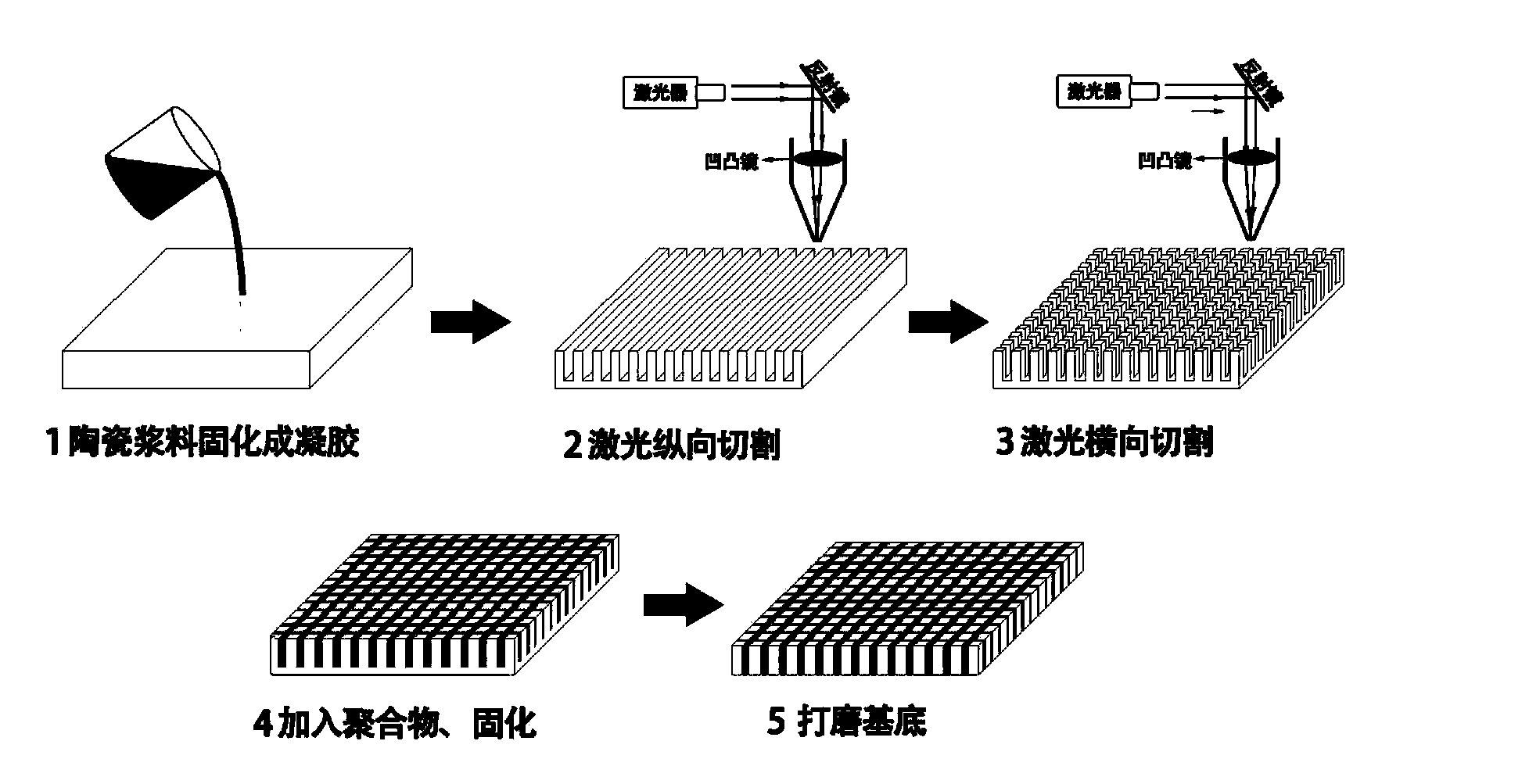

A technology of piezoelectric ceramics and composite materials, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, device material selection, etc., can solve acoustic transduction The difficulty of preparation and preparation of device composite materials, etc., to achieve the effect of flexible cutting path, simple operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

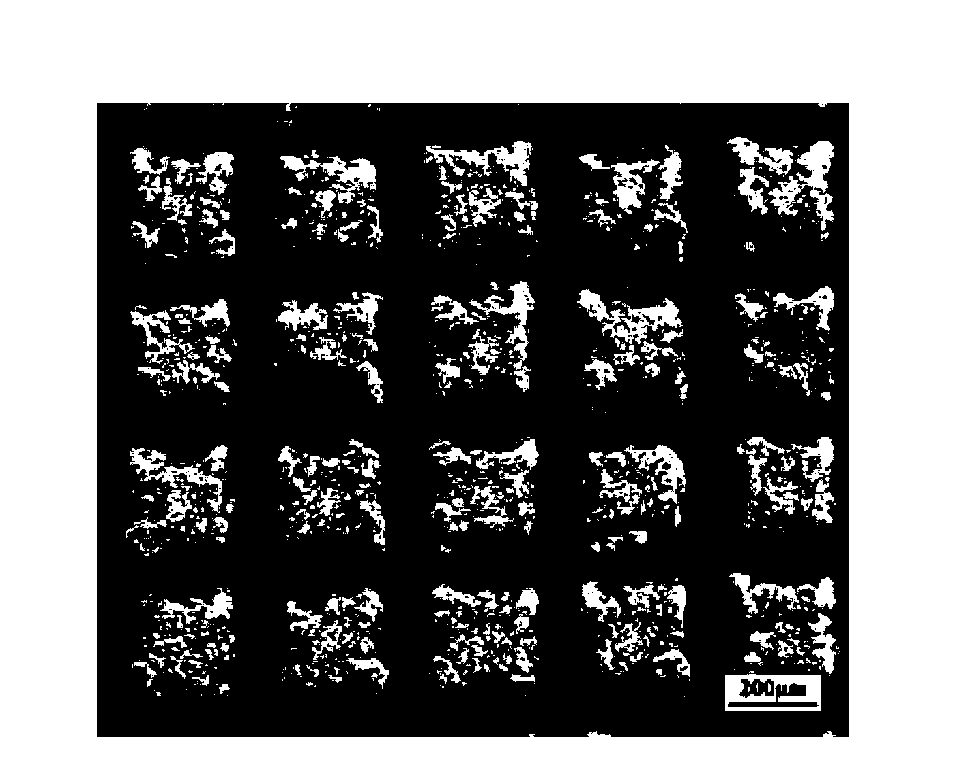

[0029] 9.1g of acrylamide (AM), 3.2g of N,N′-methylenebisacrylamide (MBAM), 135g of lead zirconate titanate powder and 2g of dispersant ammonium citrate were mixed with 20g of dewatered ball mill to obtain a volume fraction of about It is about 20mL of 45Vol% low-viscosity ceramic slurry, add 13μg initiator and 20μl catalyst, vacuumize and remove air, pour it into a ring mold with a diameter of 5cm placed on a flat plate, and place it in an oven at 68°C for 3 hours , and then remove the mold and heat at 50°C for 48 hours. After fully curing, drying and shrinking, the mold is released to obtain a ceramic green body with a strength greater than 15MPa. The Nd:YAG acousto-optic Q-switched laser with a wavelength of 1064nm is used to cut two vertically and horizontally on the green body. The SEM image of a small column array with a side length of 200 μm and a height of 1 mm is as follows figure 2 Shown; then sintered at 1260 ° C for 3 hours. After cooling, the sintered body is fi...

Embodiment 2

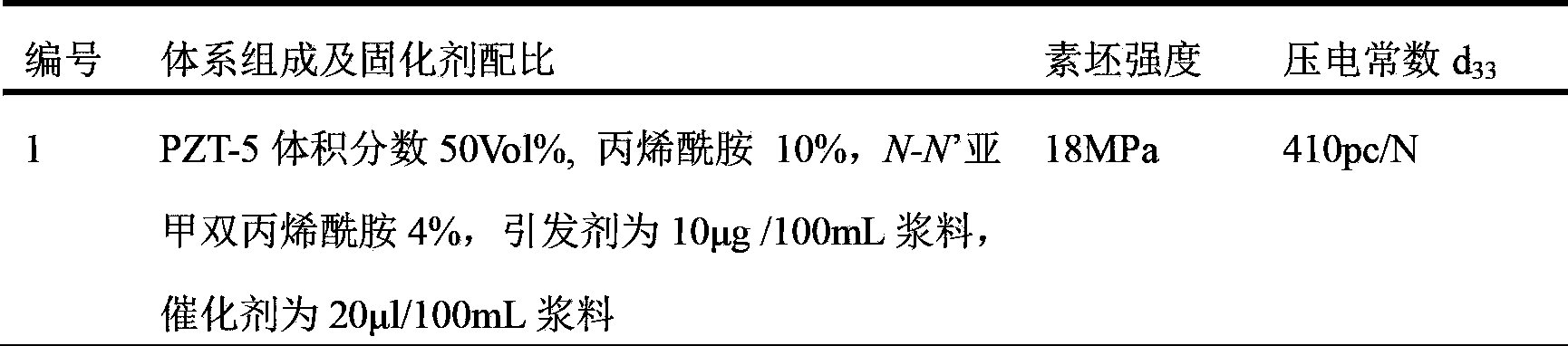

[0031] Mix 5g of acrylamide (AM), 1.6g of N,N′-methylenebisacrylamide (MBAM), 75g of lead zirconate titanate powder and 1g of dispersant ammonium citrate with 10g of dehydrated water to obtain a volume fraction of about Add about 20mL of 50Vol% low-viscosity ceramic slurry, add 6μg initiator and 10μl catalyst, vacuumize and remove air, pour it into a ring mold with a diameter of 5cm placed on a flat plate, and place it in an oven at 60°C for 3 hours. Then remove the mold and heat at 40°C for 48 hours, and release the mold after fully curing, drying and shrinking to obtain a ceramic green body with a strength greater than 15MPa, and use Nd:YAG acousto-optic Q-switched laser with a wavelength of 1064nm to cut two columns vertically and horizontally on the green body A small column array with a side length of 800 μm and a height of 3 mm was then sintered at 1260° C. for 3 hours. After cooling, the sintered body is filled with epoxy resin, cured at room temperature for 48 hours, a...

Embodiment 3

[0033]15.5g of acrylamide (AM), 5g of N,N′-methylenebisacrylamide (MBAM), 196g of niobium nickel lead zirconate titanate powder and 2g of dispersant sodium polyacrylate were mixed with 30g of deionized water and ball-milled to obtain high Solid-phase low-viscosity ceramic slurry, add 2μg initiator and 18μl catalyst, vacuumize and remove air bubbles, pour into a ring mold with a diameter of 13cm placed on a flat plate, then remove the mold and heat at 60°C for 3 hours , and then remove the mold and keep it warm at 38°C for 72 hours. After fully curing, drying and shrinking, the mold is released to obtain a ceramic green body with a strength greater than 15MPa. A row of edges is cut on the green body with an Nd:YAG acousto-optic Q-switched laser with a wavelength of 1064nm. An array of ceramic sheets with a length of 700 μm and a height of 2.5 mm is then sintered at 1250° C. for 3 hours. The sintered body is filled with epoxy resin, and the base is cut off to obtain a 2-2 piezoe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com