American window solder and seamless welding method using same

A seamless welding, American window technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as deterioration, solder joint breakage, Pb-Sn solder usage restrictions, etc., to reduce the brazing temperature , The effect of low brazing temperature and long service life

Inactive Publication Date: 2014-07-16

ANHUI WEISIJIA ENERGY SAVING WINDOWS & DOORS

View PDF10 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in recent years, environmental protection awareness has increased, and the RoHS regulations have regulated lead, which has restricted the use of lead-containing Pb-Sn solder, and began to use so-called "lead-free solder" that does not contain lead.

The currently used Sn-Ag-Cu solder alloy is used as lead-free solder. Although the scope of application of lead-free solder alloy is expanding, its solder joints are prone to breakage and deterioration in some environments.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

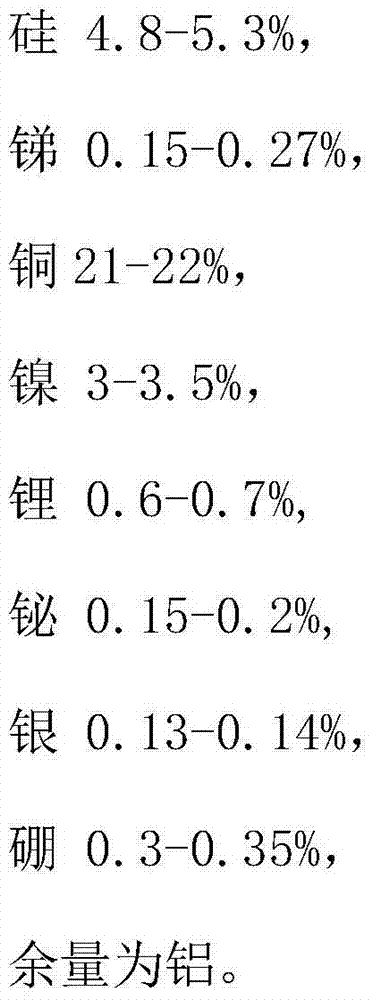

Embodiment 2

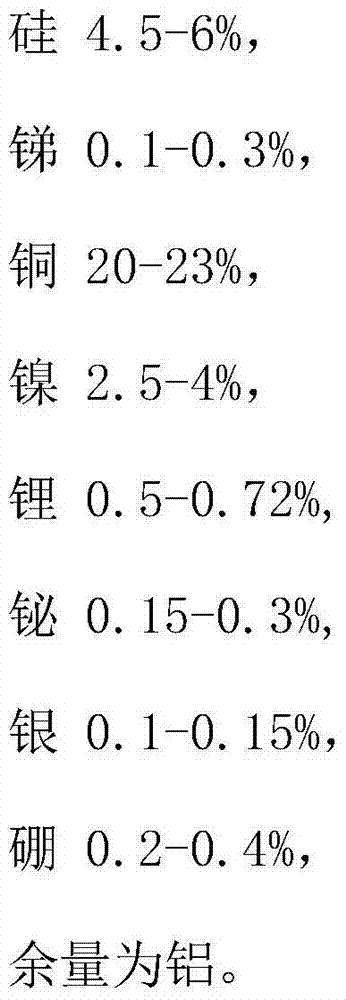

[0026] A kind of American window solder, its raw material comprises by weight:

[0027]

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

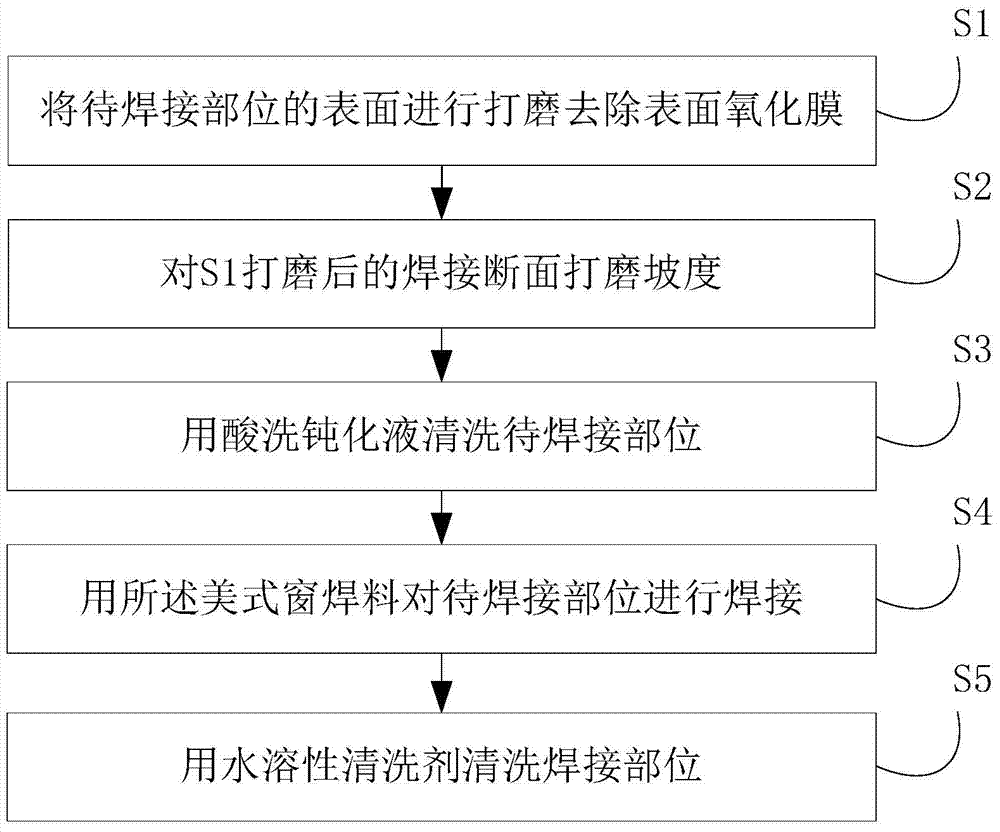

The invention discloses American window solder. The American window solder is made with, by weight, 4.5-6% of silicon, 0.1-0.3% of antimony, 20-23% of copper, 2.5-4% of nickel, 0.5-0.72% of lithium, 0.15-0.3% of bismuth, 0.1-0.15% of silver, 0.2-0.4% of boron, and the balance of aluminum. The invention further discloses a seamless welding method using the American window solder. The seamless welding method includes: polishing the surface of a part to be welded so as to remove a surface oxide film; polishing the polished weld break to obtain a slope; cleaning the part to be welded, with pickling passivating solution; welding the part to be welded, with the American window solder; cleaning the welded part with water-soluble cleaner. The American window solder is low in soldering temperature, good in heat resisting cycling performance, good in wear resistance and corrosion resistance and excellent in mechanical properties.

Description

technical field [0001] The invention relates to the technical field of solder, in particular to an American window solder and a seamless welding method thereof. Background technique [0002] Solder is a general term for metal alloy materials used to add to welds, overlays and brazes. The main function of solder is to connect the objects to be soldered and form a channel for the circuit. Commonly used soldering tin has the following conditions: the melting point of the solder is lower than that of the workpiece to be welded, it is easy to integrate with the workpiece to be welded, it has a certain resistance to pressure, it must have better electrical conductivity and a faster crystallization speed. However, in recent years, awareness of environmental protection has increased, and RoHS regulations have regulated lead, which has restricted the use of lead-containing Pb-Sn solder, and began to use so-called "lead-free solder" that does not contain lead. The currently used Sn-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K35/28

CPCB23K1/00B23K1/20B23K1/206B23K35/286

Inventor 冯玉鹏

Owner ANHUI WEISIJIA ENERGY SAVING WINDOWS & DOORS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com