Method of extracting high-purity fluosilicic acid and silicon dioxide by utilizing industrial fluorine-containing tail gas acid

A pure silicon dioxide, silicon dioxide technology, applied in the direction of silicon dioxide, silicon oxide, silicon halide compounds, etc., can solve the problem of difficulty in removing dust particles, and achieve a novel production process, high purity, high commercial value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

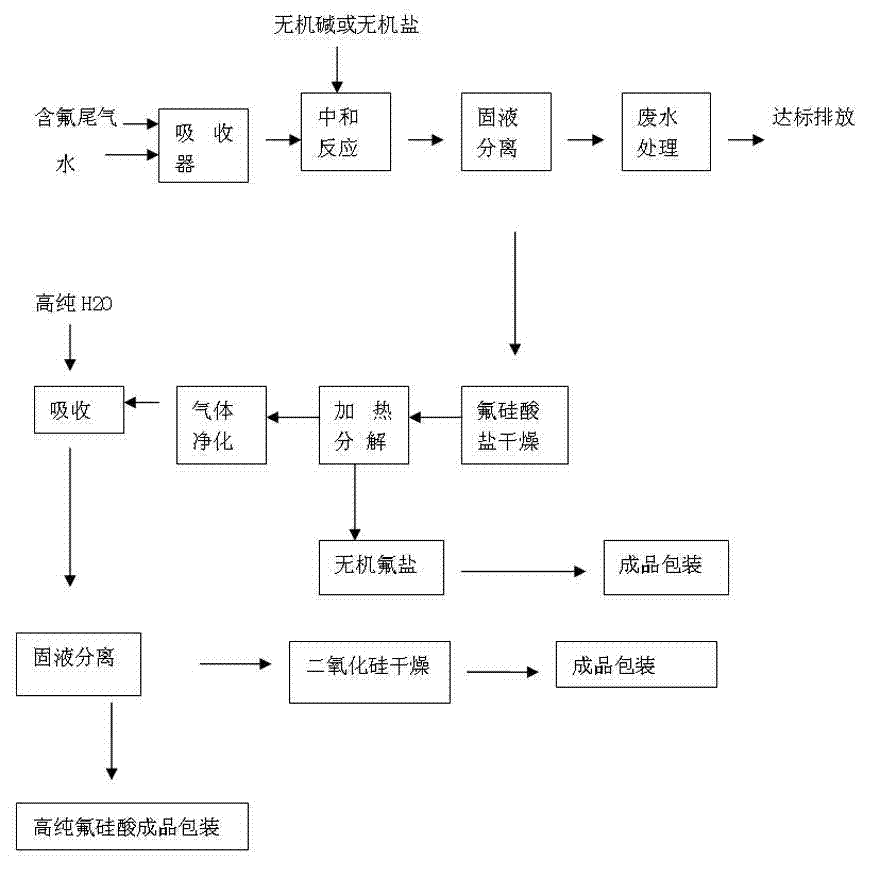

Image

Examples

no. 1 example

[0027] Preliminary impurity removal step: add Huangdan powder to the industrial fluorine-containing tail gas acid to remove sulfate ions in the fluorosilicic acid, and then filter the industrial fluorine-containing tail gas acid to remove solid impurities.

[0028] The next steps are:

[0029] Step 1, mixing sodium hydroxide with industrial fluorine-containing tail gas acid, and generating sodium fluorosilicate precipitate after fully reacting;

[0030] The reaction formula is: H 2 SiF 6 +2NaOH→Na 2 SiF 6 ↓+2H 2 O;

[0031] Step 2: Centrifuging and dehydrating the sodium fluorosilicate precipitate, and washing the impurities attached to the sodium fluorosilicate precipitate with a small amount of water; the residual liquid filtered off is subjected to wastewater treatment and discharged after reaching the standard.

[0032] Step 3, putting the sodium fluorosilicate precipitate into a desiccator and drying to below 1% water content (by weight) to obtain dry sodium fluoro...

no. 2 example

[0045] Preliminary impurity removal step: add Huangdan powder to the industrial fluorine-containing tail gas acid to remove sulfate ions in the fluorosilicic acid, and then filter the industrial fluorine-containing tail gas acid to remove solid impurities.

[0046] The next steps are:

[0047] Step 1, mixing sodium chloride with industrial fluorine-containing tail gas acid, and generating sodium fluorosilicate precipitate after fully reacting;

[0048] The reaction formula is: H 2 SiF 6 +2NaCL→Na 2 SiF 6 +2HCL;

[0049] Step 2: Centrifuging and dehydrating the sodium fluorosilicate precipitate, and washing off the HCL impurities attached to the sodium fluorosilicate precipitate with a small amount of water; the filtered residual liquid is treated with waste water and discharged after reaching the standard.

[0050] Step 3, putting the sodium fluorosilicate precipitate into a desiccator and drying to below 1% water content (by weight) to obtain dry sodium fluorosilicate; ...

no. 3 example

[0061] Preliminary impurity removal step: add Huang Dan powder to the industrial fluorine-containing tail gas acid to remove sulfate ions in the fluorosilicate acid, and then filter the industrial fluorine-containing tail gas acid to remove solid impurities.

[0062] The next steps, in order, are:

[0063] Step 1, mixing potassium chloride with industrial fluorine-containing tail gas acid, fully reacting to generate potassium fluorosilicate precipitate;

[0064] The reaction formula is: H 2 SiF 6 +2KCL→K 2 SiF 6 +2HCL;

[0065] Step 2: Centrifuge and dehydrate the potassium fluorosilicate precipitate, and wash away the HCL impurities attached to the potassium fluorosilicate precipitate with a small amount of water; the filtered residual liquid is treated with waste water and discharged after reaching the standard.

[0066] Step 3, putting the potassium fluorosilicate precipitate into a desiccator and drying until the water content (in parts by weight) is below 1%, to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com