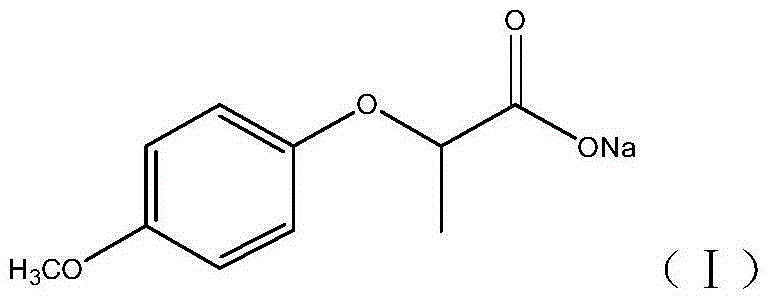

A kind of industrial production method of 2-(4-methoxyphenoxy) sodium propionate

A methoxyphenoxy and production method technology, applied in the field of compound preparation, can solve the problems of high energy consumption, complex purification steps, low product purity and the like, and achieve mild reaction conditions, simplified production procedures and high product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

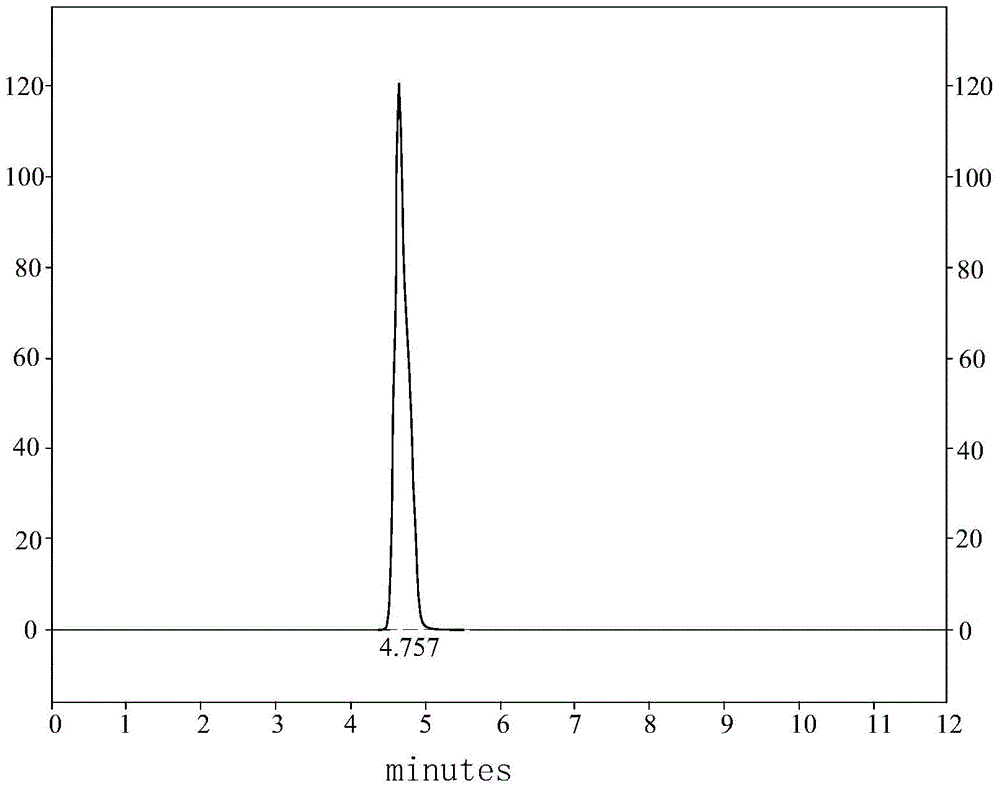

Examples

Embodiment 1

[0028] An industrial production method of sweet taste inhibitor 2-(4-methoxyphenoxy) sodium propionate, the specific processing steps include:

[0029] (1) Take the following raw materials: 10kg of p-methoxyphenol, 10kg of sodium hydroxide, 0.12kg of potassium iodide, and 100kg of water, add them to the reaction vessel, stir at room temperature for 30 minutes, and heat the reaction vessel after mixing evenly to make The above mixed raw materials are heated up to 60°C, and the temperature is kept at 60°C to 70°C, and 11.85kg of methyl 2-chloropropionate is added dropwise thereto. Under the action of catalyst potassium iodide, p-methoxyphenol and Methyl 2-chloropropionate reacts, keep the temperature during the reaction at 60°C-90°C, and at the same time, sodium hydroxide is continuously neutralized with the acid generated in the reaction, so that the reaction is always in the direction of positive reaction. After 12 hours of reaction Finish;

[0030] (2) Cool the product to no...

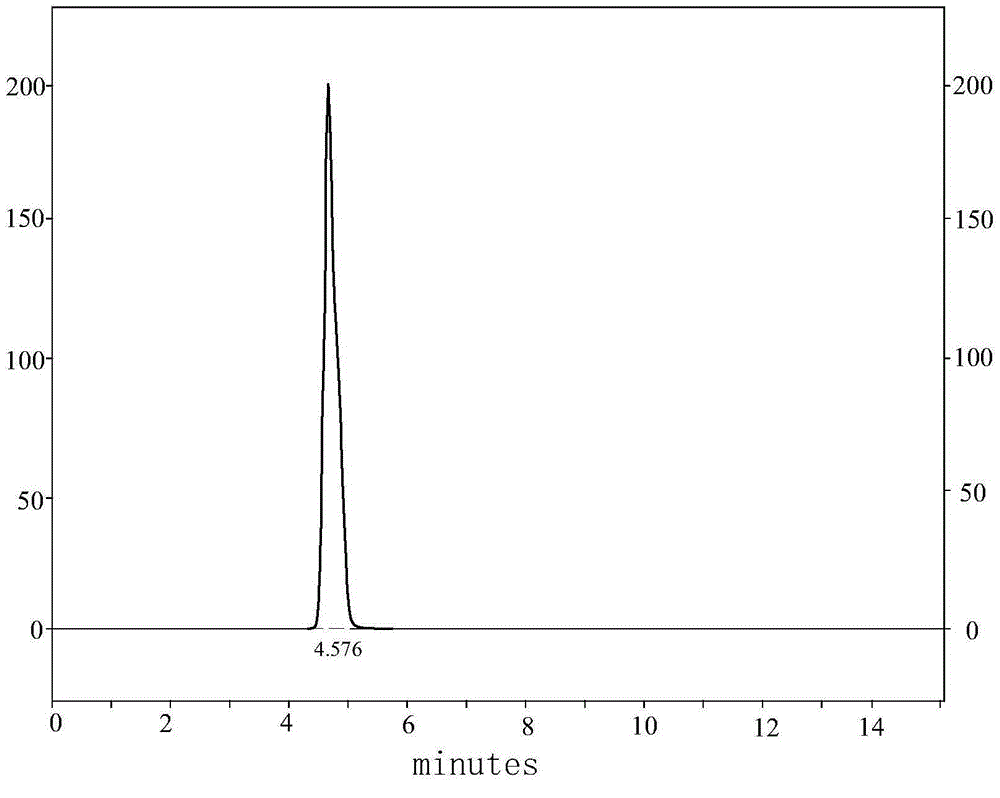

Embodiment 2

[0042] An industrial production method of sweet taste inhibitor 2-(4-methoxyphenoxy) sodium propionate, the specific processing steps include:

[0043] (1) Add 10kg of p-methoxyphenol, 10kg of sodium hydroxide, 0.12kg of sodium iodide, and 100kg of water into the reaction vessel, stir at room temperature for 30 minutes, mix the raw materials evenly, and then heat the reaction vessel to make the mixed The raw material is heated to 60°C, and the temperature of the mixed raw material is kept at 60°C to 70°C, 11.85kg of methyl 2-chloropropionate is added thereto, and stirred while adding, after adding methyl 2-chloropropionate, Continue heating to keep the reaction temperature at 90°C, and end the reaction after 12 hours;

[0044] (2) Cool the product to normal temperature, add a sulfuric acid solution with a mass fraction of 50% to the reacted mixed solution dropwise until the pH of the mixed solution is 2.0, stop the dropwise addition, and then lower the temperature of the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com