Flame-retardant polyurethane film and preparation method thereof

A technology of polyurethane film and polyurethane resin, applied in the field of flame-retardant polyurethane film and its preparation, can solve the problems of waterproof, reduced air permeability, improved fire resistance of polyurethane film, reduced polyurethane film, etc., and achieves good waterproof and air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

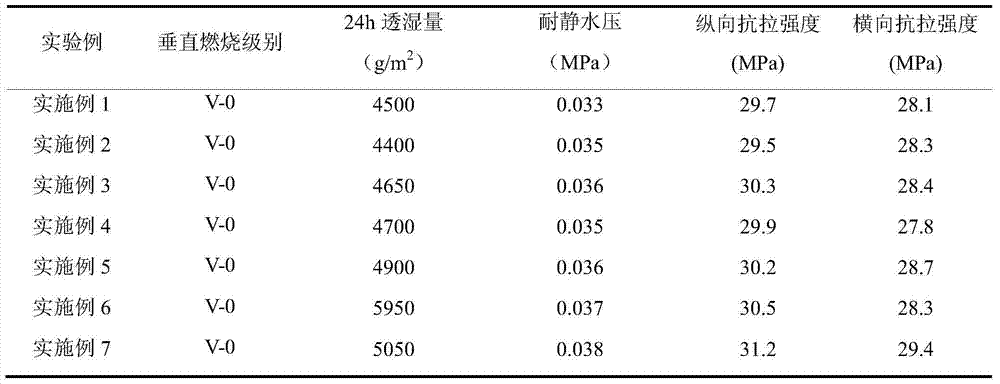

Examples

Embodiment 1

[0035]Example 1: The fireproof polyurethane resin and 0.4% of ZBJ-002 and 0.4% of ZBJ-003 based on the mass of the fireproof polyurethane resin were fully mixed under the stirring of a mixer with a rotation speed of 1000rpm to form a mixed resin. Add 1% OK-412 matting powder based on the mass of fire-resistant polyurethane resin into an organic solvent composed of 15% butanone, 25% toluene and 25% N,N-dimethylformamide based on the mass of fire-resistant polyurethane resin, A mixed solution was formed under the stirring of a high-speed stirrer at 2500 rpm. According to the addition amount of 30%, 30% and 40%, the mixed liquid is added to the mixed resin in three times and stirred by a mixer at 200 rpm to obtain glue. Next, put the glue into a foam maker, and foam for a certain period of time under the conditions of a foaming ratio of 4 and a flow rate of 8g / s to obtain a water-based polyurethane foam. Then, the water-based polyurethane foam was coated on the release paper, pl...

Embodiment 2

[0036] Example 2: The fireproof polyurethane resin and 0.6% of ZBJ-002 and 0.6% of ZBJ-003 based on the mass of the fireproof polyurethane resin were fully mixed under the stirring of a mixer with a rotation speed of 1200rpm to form a mixed resin. Add 2% OK-412 matting powder based on the mass of fire-resistant polyurethane resin into an organic solvent composed of 20% methyl ethyl ketone, 15% toluene and 35% N,N-dimethylformamide based on the mass of fire-resistant polyurethane resin , form a mixed solution under the stirring of a high-speed stirrer at 3000rpm. According to the addition amount of 30%, 30% and 40%, the mixed solution was added to the mixed resin in three times and stirred by a mixer at 250rpm to obtain glue. Next, put the glue into a foam maker, and foam for a certain period of time according to the conditions of a foaming ratio of 4.5 and a flow rate of 9g / s to obtain a water-based polyurethane foam. Then, the water-based polyurethane foam was coated on the ...

Embodiment 3

[0037] Example 3: The fireproof polyurethane resin, 0.45% of ZBJ-002 and 0.4% of ZBJ-003 based on the mass of the fireproof polyurethane resin were fully mixed under the agitation of a mixer with a rotation speed of 1300rpm to form a mixed resin. Add 1% OK-412 matting powder based on the mass of fire-resistant polyurethane resin into an organic solvent composed of 20% methyl ethyl ketone, 15% toluene and 35% N,N-dimethylformamide based on the mass of fire-resistant polyurethane resin , form a mixed solution under the stirring of a high-speed mixer at 3100rpm. According to the addition amount of 30%, 30% and 40%, the mixed solution was added to the mixed resin in three times and stirred by a mixer at 300 rpm to obtain glue. Next, put the glue into a foam maker, and foam for a certain period of time according to the conditions of a foaming ratio of 5 and a flow rate of 10 g / s to obtain a water-based polyurethane foam. Then, the water-based polyurethane foam was coated on the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com