Waterproof breathable tear-resistant fabric as well as preparation method and application thereof

A waterproof, breathable, and tear-resistant technology, applied in the field of fabrics, can solve the problems of fabrics being easily scratched, the overall weight, and down running out, etc., to achieve increased water repellency, excellent waterproof breathability, and increased tensile and tear resistance intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

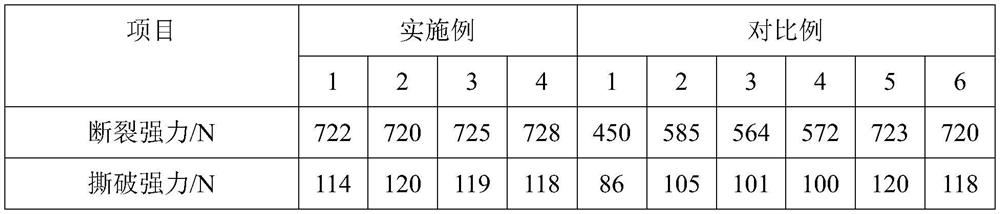

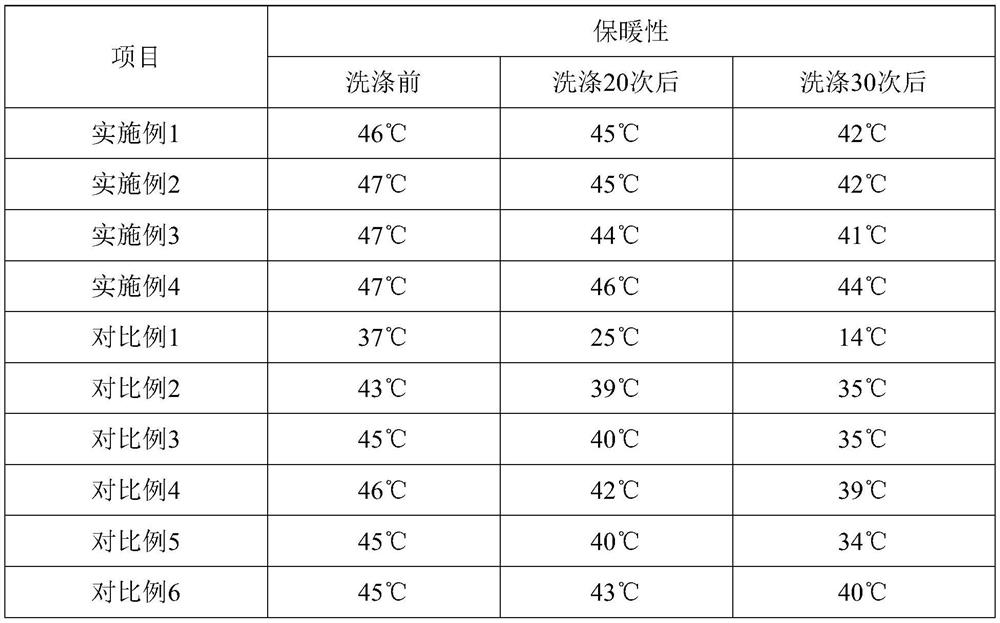

Examples

Embodiment 1

[0022] The preparation method of the waterproof, breathable and tear-resistant fabric in this embodiment comprises the following steps:

[0023] (1) Cotton thread treatment: Soak the cotton thread in an aqueous solution that adds fruit acid and silver-loaded antibacterial agent. post-drying;

[0024] (2) Fiber preparation: After grinding the leftovers of the carbon fiber soft felt made of polyacrylonitrile-based carbon fiber, sieve and twist the yarn to obtain the initial carbon fiber, and carbonize it at a temperature of 900-1000°C in a nitrogen environment to obtain carbon fiber;

[0025] (3) thread making: the cotton thread obtained in step (1) and the carbon fiber and polypropylene fiber obtained in step (2) are combined and twisted to make fabric thread after carding;

[0026] (4) Preparation of the fabric: The fabric thread is used as the warp and weft, and the initial fabric is woven by textile equipment, and it is rotated in a roll machine environment at 100-120°C for...

Embodiment 2

[0028] The preparation method of the waterproof, breathable and tear-resistant fabric in this embodiment comprises the following steps:

[0029] (1) Cotton thread treatment: Soak the cotton thread in an aqueous solution that adds fruit acid and silver-loaded antibacterial agent. post-drying;

[0030] (2) Fiber preparation: After grinding the leftovers of the carbon fiber soft felt made of polyacrylonitrile-based carbon fiber, sieve and twist the yarn to obtain the initial carbon fiber, and carbonize it at a temperature of 900-1000°C in a nitrogen environment to obtain carbon fiber;

[0031] (3) thread making: the cotton thread obtained in step (1) and the carbon fiber and polypropylene fiber obtained in step (2) are combined and twisted to make fabric thread after carding;

[0032] (4) Preparation of the fabric: The fabric thread is used as the warp and weft, and the initial fabric is woven by textile equipment, and it is rotated in a roll machine environment at 100-120°C for...

Embodiment 3

[0034] The preparation method of the waterproof, breathable and tear-resistant fabric in this embodiment comprises the following steps:

[0035] (1) Cotton thread treatment: Soak the cotton thread in an aqueous solution that adds fruit acid and silver-loaded antibacterial agent. post-drying;

[0036] (2) Fiber preparation: After grinding the leftovers of the carbon fiber soft felt made of viscose-based carbon fiber, sieve and twist the yarn to obtain the initial carbon fiber, and carbonize it at 900-1000°C in a nitrogen environment to obtain carbon fiber;

[0037] (3) thread making: the cotton thread obtained in step (1) and the carbon fiber and polypropylene fiber obtained in step (2) are combined and twisted to make fabric thread after carding;

[0038] (4) Preparation of the fabric: The fabric thread is used as the warp and weft, and the initial fabric is woven by textile equipment, and it is rotated in a roll machine environment at 100-120°C for 5-10min, and the water rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com