Low-viscidity flexible cement paste for well cementation with slim hole and single channel

A single-hole, viscous-flexible technology, applied in the field of cementing slurry, to achieve the effects of reduced permeability, low water loss, and improved wall shearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

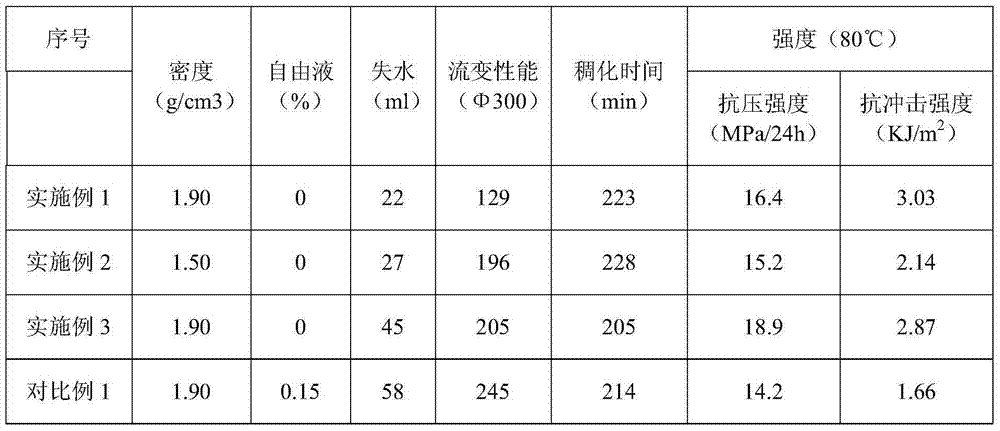

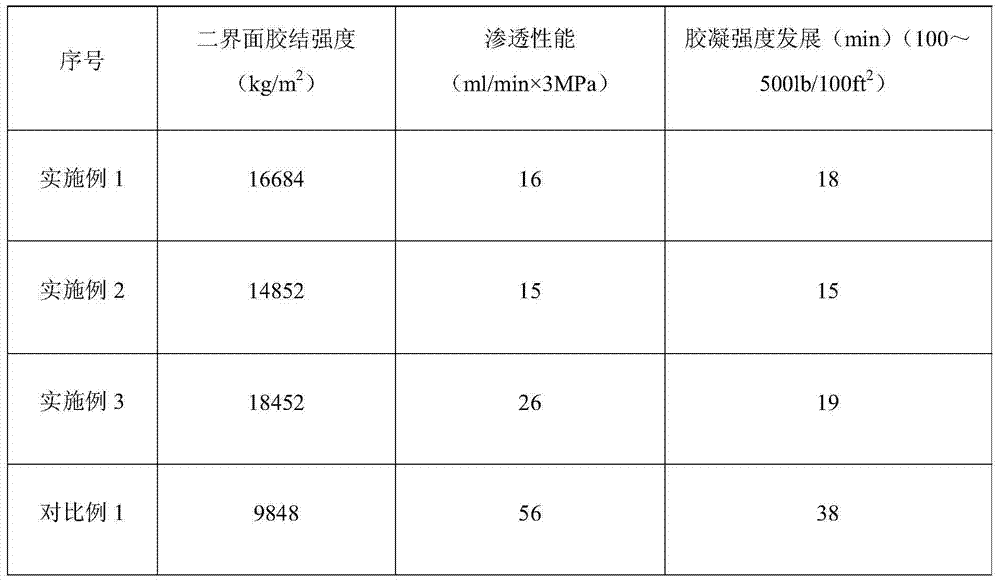

Embodiment 1

[0060] Embodiment 1, low-viscosity flexible cement slurry

[0061] Cement slurry formula: D grade oil well cement + 37.5% fresh water + 6.25% pore proppant + 3.75% fluid loss reducer (acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, relative molecular weight is 1 million to 200 Ten thousand) + 0.625% anti-foaming and defoaming agent + 1.25% elastic emulsion (styrene-butadiene latex, the effective content of which is 50%) + 1.5% dispersant + 0.125% retarder (citric acid) + 0.5% expansion agent (sodium oxide), the percentage of each of the above components refers to the percentage of cement weight.

[0062] The density of the low-viscosity flexible cement slurry prepared in this embodiment is 1.90g / cm 3 .

Embodiment 2

[0063] Embodiment 2, low-viscosity flexible cement slurry

[0064] Cement slurry formula: D-grade oil well cement + 56% fresh water + 12% reinforcing agent (composed of ultra-fine slag with a particle size of 15 μm and microsilica fume with a particle size of 5 μm) + 6% pore proppant + 10% floating beads+ 5% fluid loss reducer (acrylamide-2-acrylamide-2-methylpropanesulfonic acid copolymer, relative molecular weight is 1.5 million to 2 million) + 1% antifoaming and defoaming agent + 2% elastic emulsion (butadiene styrene Latex, wherein the effective content of styrene-butadiene latex is 55%) + 0.5% dispersant (magnesium oxide), the percentage of the above components refers to the percentage of cement weight.

[0065] The density of the low-viscosity flexible cement slurry prepared in this embodiment is 1.50g / cm 3 .

Embodiment 3

[0066] Embodiment 3, low-viscosity flexible cement slurry

[0067] Cement slurry formula: D-grade oil well cement + 41.3% fresh water + 8.3% pore proppant + 5% fluid loss reducer (N,N-dimethylacrylamide) + 0.83% anti-foaming and defoaming agent + 1.7% elastic emulsion ( Styrene-butadiene latex, wherein the effective content of styrene-butadiene latex is 55%) + 2% dispersant (sodium oxide) + 1.13% retarder (boric acid) + 35% silica fume, the percentage of the above components refers to the weight of cement percentage.

[0068] The density of the low-viscosity flexible cement slurry prepared in this embodiment is 1.90g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com