Silicon acrylic emulsion printing adhesive

A silicone-acrylic emulsion and adhesive technology, which is applied in the chemical industry, can solve the problems of unsatisfactory rubbing fastness of printed fabrics, poor air permeability and comfort of the film, and viscosity at high temperature, and achieves soft film formation, elastic film formation, The effect of high film strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

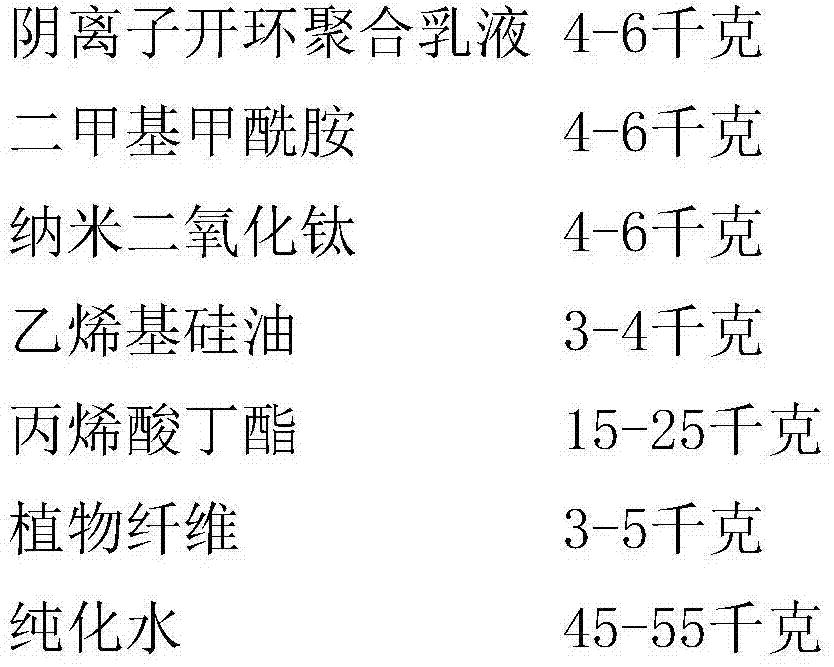

[0023] A silicone acrylic emulsion printing adhesive consisting of the following ingredients by weight,

[0024]

[0025] The anionic ring-opening polymerization emulsion is the emulsion synthesized by ring-opening emulsion polymerization of cyclosiloxane in the presence of an anionic catalyst.

[0026] The preparation method of silicone acrylic emulsion printing adhesive of the present invention is as follows:

[0027] 1) Weigh each component according to the above formula, first put purified water, tert-butanol and methanol into the reaction kettle, stir and mix evenly, heat to 50-60°C, and prepare solution a for use;

[0028] 2) Dissolve nano-titanium dioxide, butyl acrylate, plant fiber, acrylic acid and anionic ring-opening polymerization emulsion into solution a, stir well and evenly, heat while stirring until the temperature reaches 80-90°C for 2 hours, and prepare solution b stand-by;

[0029] 3) Put hydrogen silicone oil, emulsifier and vinyl silicone oil into so...

Embodiment 2

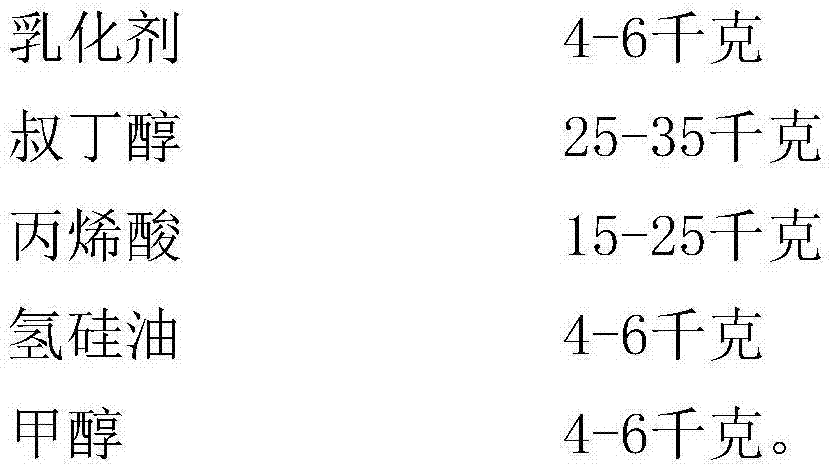

[0033] A silicone acrylic emulsion printing adhesive consisting of the following ingredients by weight,

[0034]

[0035] The anionic ring-opening polymerization emulsion is the emulsion synthesized by ring-opening emulsion polymerization of cyclosiloxane in the presence of an anionic catalyst.

[0036] The preparation method of silicone acrylic emulsion printing adhesive of the present invention is as follows:

[0037] 1) Weigh each component according to the above formula, first put purified water, tert-butanol and methanol into the reaction kettle, stir and mix evenly, heat to 50-60°C, and prepare solution a for use;

[0038] 2) Dissolve nano-titanium dioxide, butyl acrylate, plant fiber, acrylic acid and anionic ring-opening polymerization emulsion into solution a, stir well and evenly, heat while stirring until the temperature reaches 80-90°C for 2 hours, and prepare solution b stand-by;

[0039] 3) Put hydrogen silicone oil, emulsifier and vinyl silicone oil into so...

Embodiment 3

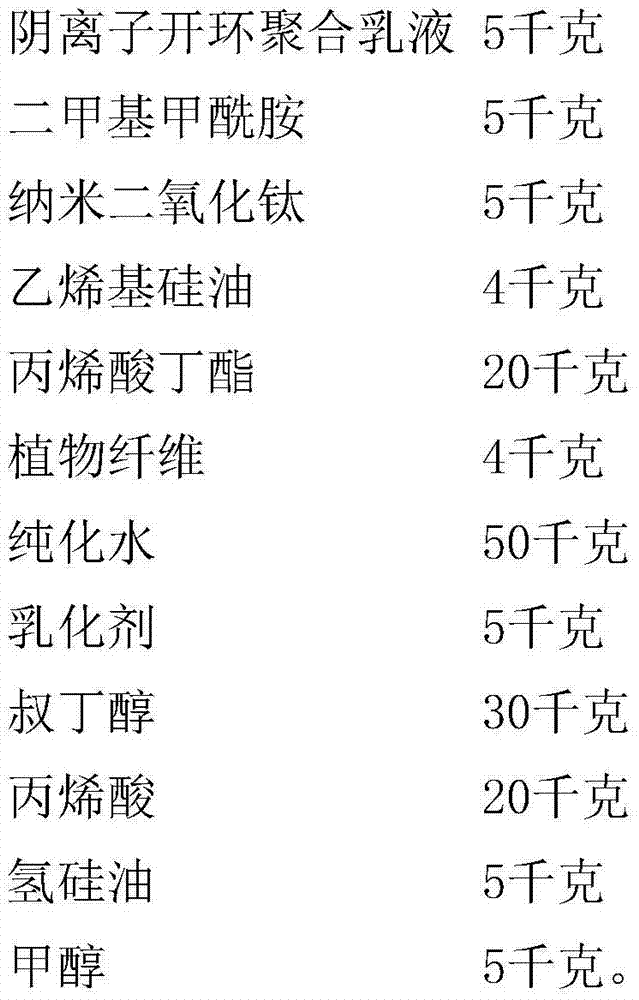

[0043] A silicone acrylic emulsion printing adhesive consisting of the following ingredients by weight,

[0044]

[0045] The anionic ring-opening polymerization emulsion is the emulsion synthesized by ring-opening emulsion polymerization of cyclosiloxane in the presence of an anionic catalyst.

[0046] The preparation method of silicone acrylic emulsion printing adhesive of the present invention is as follows:

[0047] 1) Weigh each component according to the above formula, first put purified water, tert-butanol and methanol into the reaction kettle, stir and mix evenly, heat to 50-60°C, and prepare solution a for use;

[0048] 2) Dissolve nano-titanium dioxide, butyl acrylate, plant fiber, acrylic acid and anionic ring-opening polymerization emulsion into solution a, stir well and evenly, heat while stirring until the temperature reaches 80-90°C for 2 hours, and prepare solution b stand-by;

[0049] 3) Put hydrogen silicone oil, emulsifier and vinyl silicone oil into so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com