Preparation method of all-silicon MFI type molecular sieve membrane with high stability

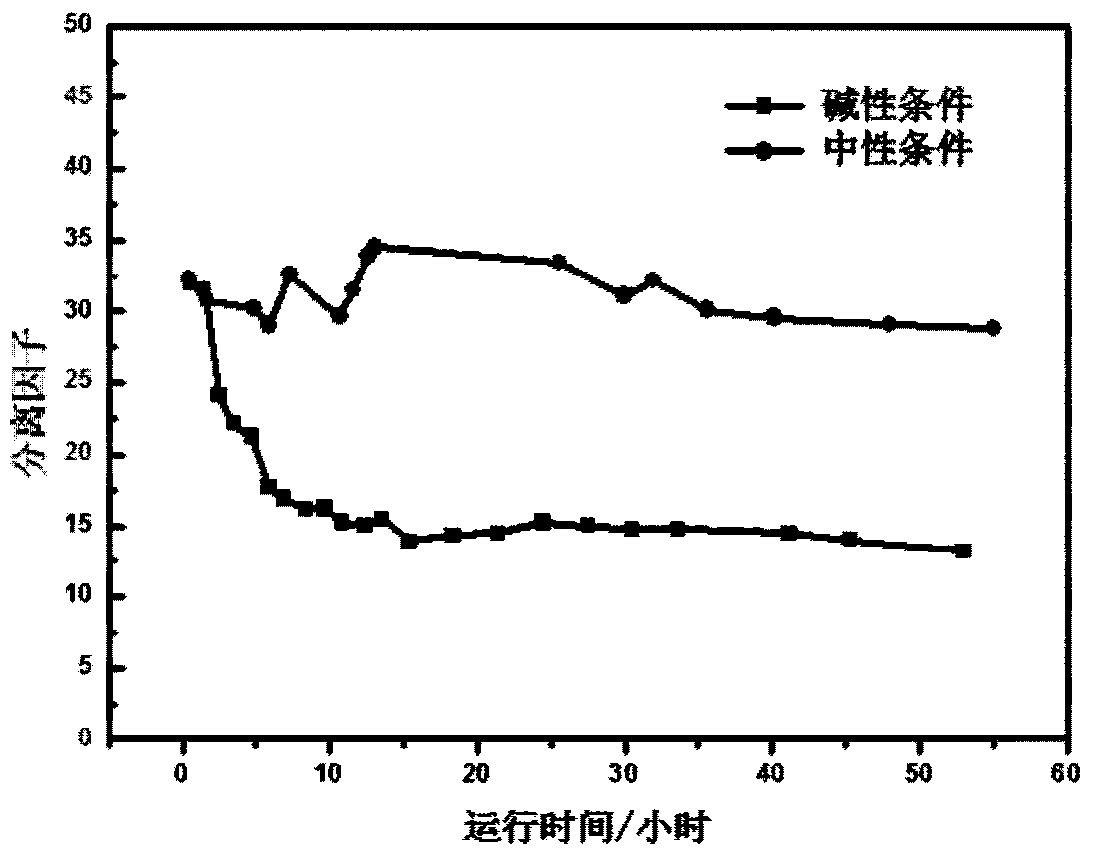

A high-stability, zeolite molecular sieve membrane technology, applied in chemical instruments and methods, pervaporation, membrane technology, etc., can solve problems such as poor membrane stability, and achieve good stability and good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

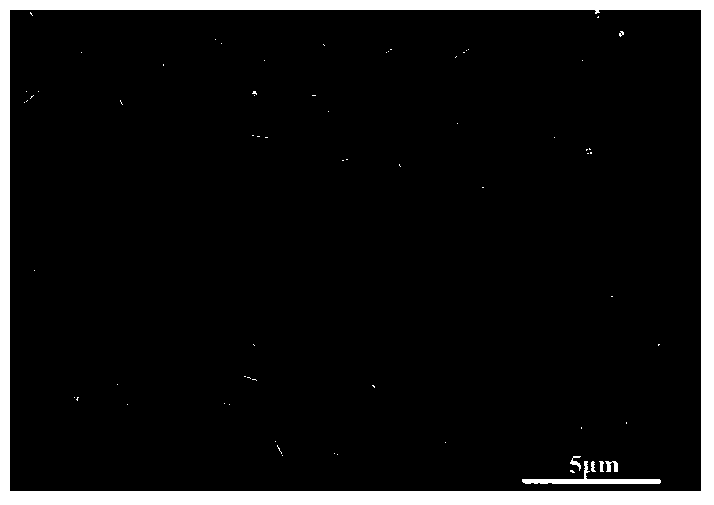

[0028] Example 1: Preparation of all-silicon MFI type zeolite molecular sieve membrane under neutral conditions

[0029] Mix 0.47g of tetrapropylammonium bromide, 1.64g of ammonium fluoride and 40.03g of water evenly, and slowly add 1.33g of fumed silica at 80°C, shake vigorously to form a stable transparent sol (nSiO 2 :nTPABr:nNH 4 F: nH 2 O=1:0.08:2:100), pour it into a polytetrafluoroethylene-lined stainless steel reactor, and then put the reactor into an oven at 180°C for crystallization for 10 hours. After the synthesis is completed, the reaction product is centrifuged, washed, and dried to obtain an all-silicon MFI zeolite molecular sieve. Using YSZ hollow fiber as a support, it was ultrasonically cleaned in deionized water for 20 min, and then dried for later use. Put the molecular sieve particles into a ball mill tank, use water as the dispersant, and ball mill for 8 hours at a speed of 200r / min. The mass ratio of water to molecular sieve is 30:1. After the ball mi...

Embodiment 2

[0031] Example 2: Preparation of all-silicon MFI type zeolite molecular sieve membrane under neutral conditions

[0032] Mix 2.36g of tetrapropylammonium bromide, 2.05g of ammonium fluoride and 40.03g of water evenly, heat in a water bath at 90°C until completely dissolved, then add 3.33g of fumed silica, and shake vigorously until a transparent sol (nSiO2:nTPABr : nNH 4 F: nH 2 O=1:0.16:1.0:40). The synthesis temperature is 160°C and the synthesis time is 24h. The obtained molecular sieve particles were put into a ball mill tank with water as a dispersant, and ball milled for 2 hours at a rotational speed of 600 r / min. The mass ratio of water to molecular sieve was 50:1. Chip α-Al 2 o 3as a support material. Preparation of molecular sieve membrane synthesis mother liquor: mix 1.18g tetrapropylammonium bromide, 0.33g ammonium fluoride and 40.03g water and heat to 90°C, add 3.33g fumed silica (nSiO 2 :nTPABr:nNH 4 F: nH 2 O=1:0.1:0.2:50), and hydrothermally synthesized...

Embodiment 3

[0033] Example 3: Preparation of all-silicon MFI type zeolite molecular sieve membrane under neutral conditions

[0034] The synthetic liquid composition of molecular sieve seed crystal is 6.67g fumed silica, 7.09g tetrapropyl ammonium bromide, 1.64g ammonium fluoride and 40.03g water (nSiO 2 :nTPABr:nNH 4 F: nH 2 O=1:0.24:0.4:20). Put the obtained molecular sieve particles into a ball mill tank, use water as a dispersant, and ball mill for 4 hours at a speed of 400 r / min. The mass ratio of water to molecular sieve is 20:1. All the other conditions and steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com