Blend membrane comprising polyvinyl acetate and polyether-b-polyamide, preparation thereof and applications thereof

A polyvinyl acetate, blended membrane technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as low mechanical strength, and achieve low mechanical strength, easy to repeat, and mild operating conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

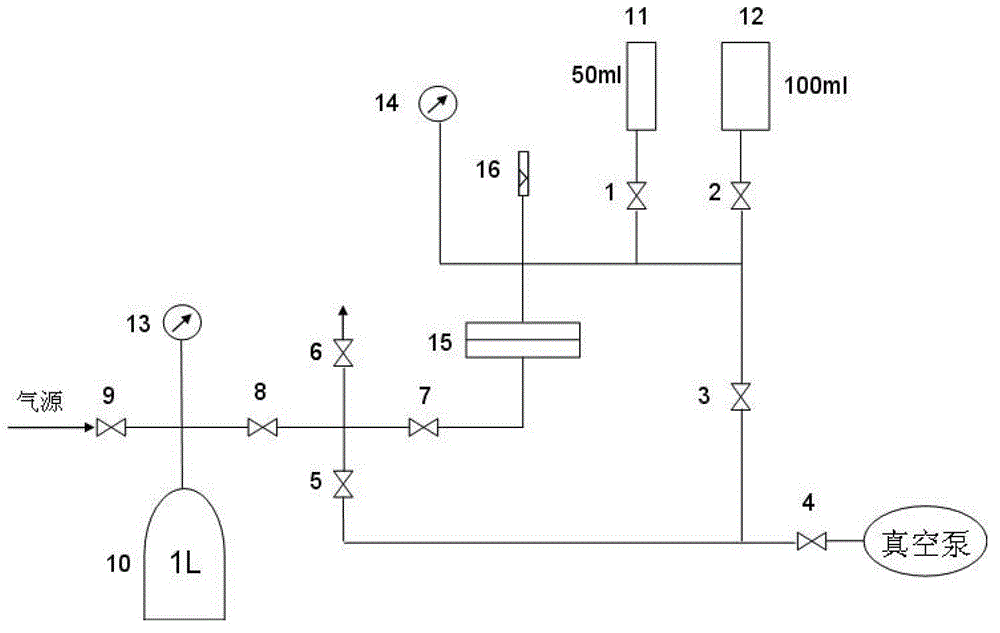

Method used

Image

Examples

Embodiment 1

[0057] Add 2.5 grams of vacuum-dried Pebax1074 (m(PEO):m(PA12)=55:45, mass ratio) to 95 grams of dimethylacetamide solvent, and stir at 80°C for 6 hours to form a uniform and transparent After the polymer solution, add 2.5 grams of PVAc to the polymer solution, continue stirring for 2 hours, and after forming a uniform and transparent solution again, carry out static defoaming, and pour the defoamed casting solution into a clean horizontal glass plate In the smooth iron ring on the top, the casting liquid is spread evenly on the glass plate, the temperature of the glass plate is kept at 50 ℃, the solvent is volatilized, and finally the primary film is formed. The primary film was carefully removed from the glass plate, placed in a vacuum oven, dried for 72 h, and the residual solvent was removed to obtain a PVAc / Pebax1074 (1 / 1) blend homogeneous film with a mass ratio of PVAc and Pebax1074 of 1:1. And test its penetration performance.

[0058] Table 1 Experimental results of ...

Embodiment 2

[0061] Add 3.5 grams of vacuum-dried Pebax1074 to 95 grams of dimethylacetamide solvent, stir at 80°C for 6 hours to form a uniform and transparent polymer solution, add 1.5 grams of PVAc to the polymer solution, continue stirring 2h, after forming a uniform and transparent solution again, carry out ultrasonic defoaming, pour the defoamed casting liquid into the smooth iron ring on a clean horizontal glass plate, so that the casting liquid spreads evenly on the glass plate, and the glass The plate temperature was kept at 50°C, solvent evaporation was carried out, and a nascent film was finally formed. The primary film was carefully removed from the glass plate, placed in a vacuum oven, dried for 72 h, and the residual solvent was removed to obtain a PVAc / Pebax1074 (3 / 7) blend homogeneous film with a mass ratio of PVAc and Pebax1074 of 3:7. And test its penetration performance.

[0062] Table 2 Experimental results of Example 2 (25°C, 5atm)

[0063]

Embodiment 3

[0065] Add 4.5 grams of vacuum-dried Pebax1074 to 95 grams of dimethylacetamide solvent, stir at 85°C for 6 hours to form a uniform and transparent polymer solution, add 0.5 grams of PVAc to the polymer solution, and continue stirring 2h, after forming a uniform and transparent solution again, carry out negative pressure defoaming; pour the defoamed casting liquid into the tetrafluoro board, so that the casting liquid spreads evenly on the tetrafluoro board, and the temperature of the glass plate is kept at 50 ℃, the solvent is evaporated, and finally a primary film is formed. The primary membrane was carefully removed from the glass plate, placed in a vacuum oven, dried for 72 hours, and the residual solvent was removed to obtain a PVAc / Pebax1074 (1 / 9) blend homogeneous membrane with a mass ratio of PVAc and Pebax1074 of 1:9. , and test its penetration performance.

[0066] Table 3 Experimental results of Example 3 (25°C, 5atm)

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com