Preparation method of Ag0.35V2O5/TiO2 nano-composite photocatalyst

A photocatalyst and nanocomposite technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., to achieve strong visible light absorption rate, cheap raw materials and equipment, and easy experimental conditions The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) 0.5g tetrabutyl titanate, 0.2g polyvinylpyrrolidone (average molecular weight: 1300000), 0.75g absolute ethanol, 0.45g dimethylacetamide and 1.25g glacial acetic acid were mixed and fully stirred for 20min, recorded as A solution.

[0025] (2) Mix 1.2g of polyvinylpyrrolidone (average molecular weight: 1,300,000), 0.4g of vanadyl bisacetylacetonate, 0.07g of silver nitrate and 7.0g of dimethylacetamide and stir them thoroughly for 20 minutes, and record it as solution B.

[0026] (3) Mix solution A and solution B and stir thoroughly for 1 hour to obtain a uniform mixed solution of polyvinylpyrrolidone / titanate / diacetylacetonate vanadyl / silver nitrate, wherein the atomic ratio of V / Ti is 1:1.

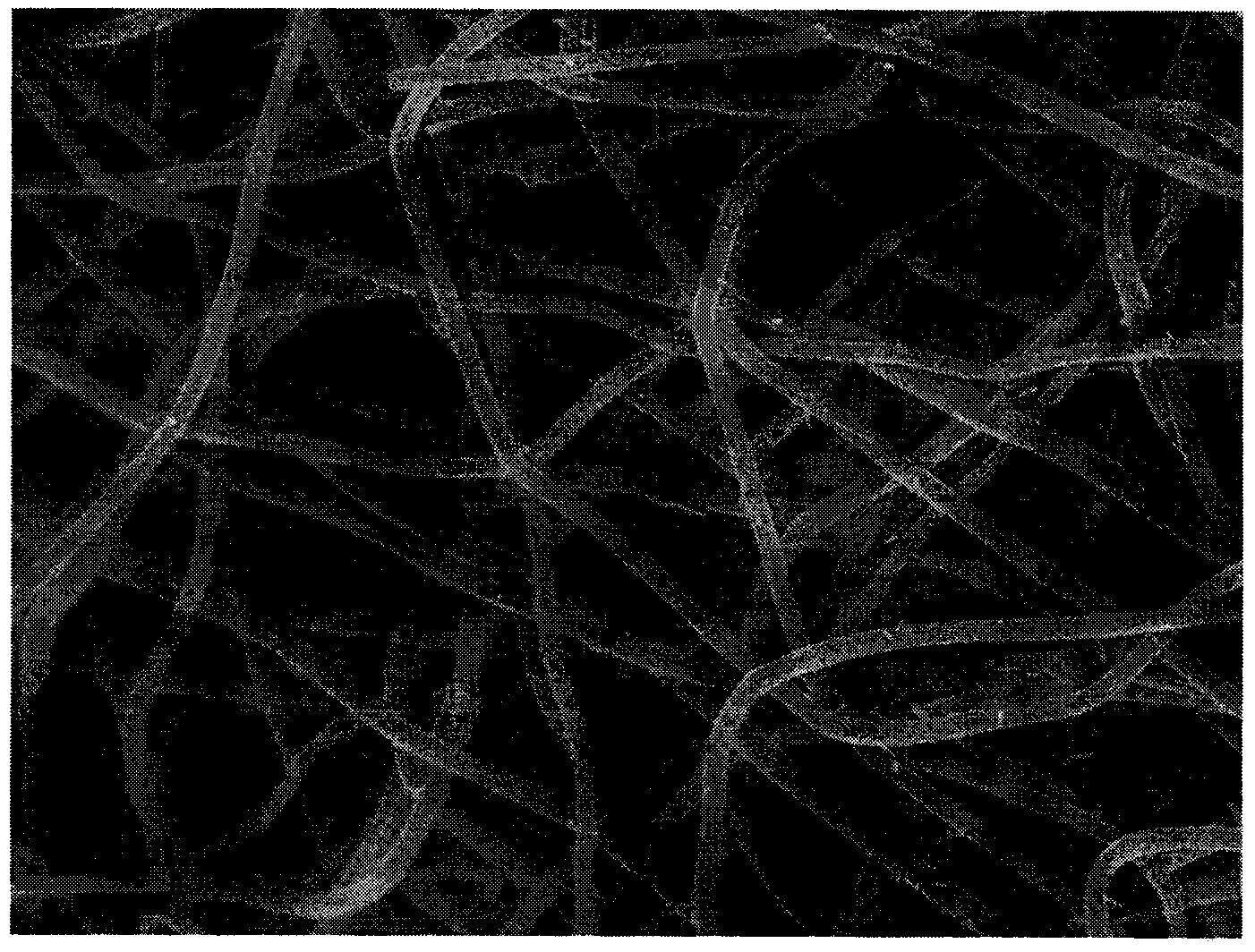

[0027] (4) Spin the viscous polyvinylpyrrolidone / titanate / bisacetylacetonate vanadyl / silver nitrate mixed solution by electrospinning to obtain nanofibers. The specific parameters of electrospinning are as follows: The hole diameter is 0.4 mm, the distance between the bottom ...

Embodiment 2

[0030] (1) With embodiment 1.

[0031] (2) Mix 0.6g of polyvinylpyrrolidone (average molecular weight: 1300000), 0.2g of vanadyl diacetylacetonate, 0.035g of silver nitrate and 3.5g of dimethylacetamide and fully stir for 20min, which is recorded as solution B.

[0032] (3) Mix solution A and solution B and stir thoroughly for 1 hour to obtain a uniform mixed solution of polyvinylpyrrolidone / titanate / diacetylacetonate vanadyl / silver nitrate, wherein the atomic ratio of V / Ti is 1:2.

[0033] (4) with embodiment 1.

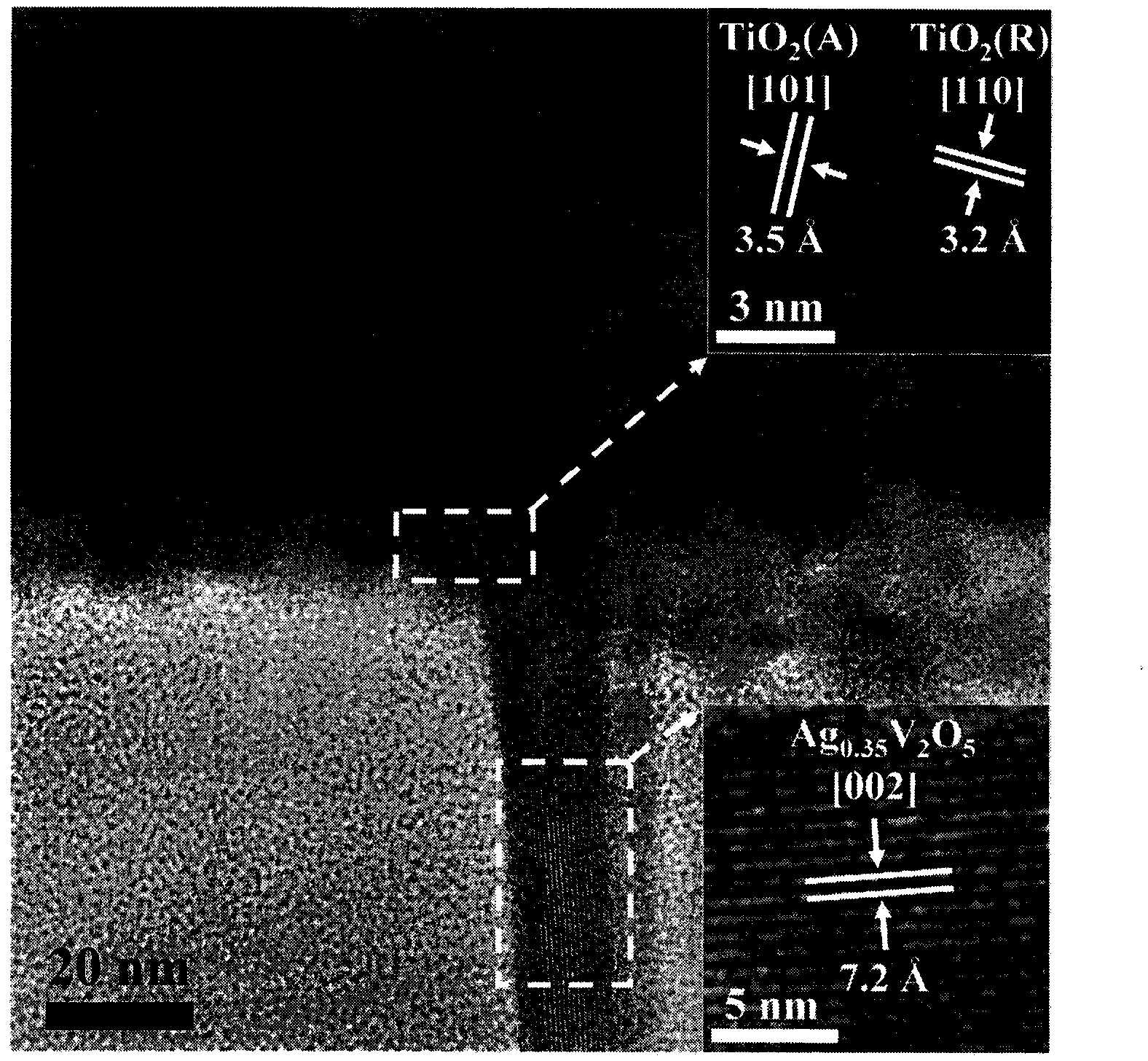

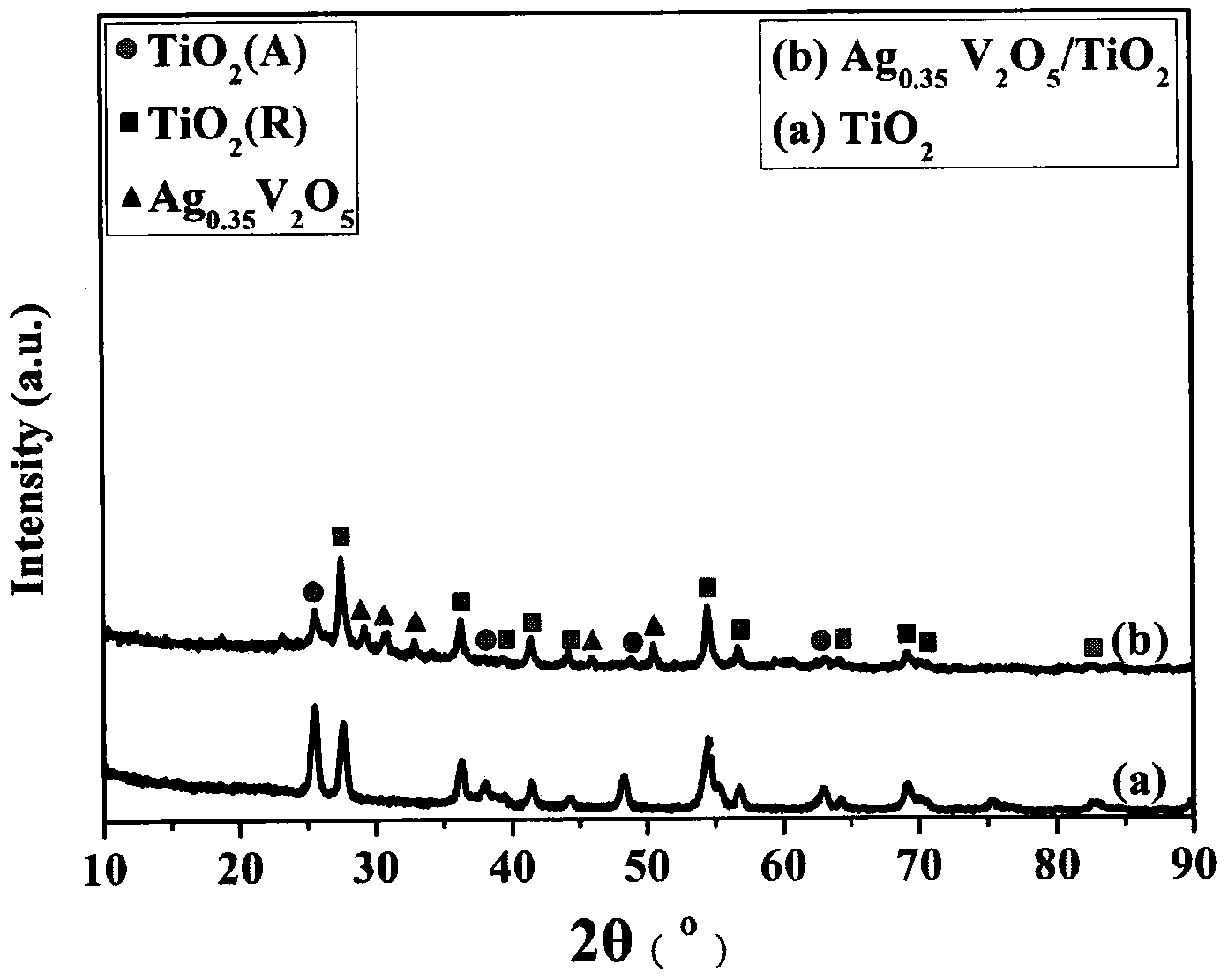

[0034] Ag obtained in this example 0.35 V 2 o 5 / TiO 2 Ag in nanocomposite photocatalysts 0.35 V 2 o 5 with TiO 2 The molar ratio is 1:4.

Embodiment 3

[0036] (1) With embodiment 1.

[0037] (2) Mix 2.4g of polyvinylpyrrolidone (average molecular weight: 1300000), 0.8g of vanadyl bisacetylacetonate, 0.14g of silver nitrate and 14.0g of dimethylacetamide and stir them thoroughly for 20 minutes, and record it as solution B.

[0038] (3) Mix solution A and solution B and stir thoroughly for 1 hour to obtain a uniform mixed solution of polyvinylpyrrolidone / titanate / diacetylacetonate vanadyl / silver nitrate, wherein the atomic ratio of V / Ti is 2:1.

[0039] (4) with embodiment 1.

[0040] Ag obtained in this example 0.35 V 2 o 5 / TiO 2 Ag in nanocomposite photocatalysts 0.35 V 2 o 5 with TiO 2 The molar ratio is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com