Weld zone machine vision device with self-adaptive liquid crystal filter screen

A technology of machine vision and filter screen, which is applied in welding equipment, auxiliary devices, welding accessories, etc., can solve the problems of interfering with the visual effect of the welding area and difficulty in realizing it, so as to reduce the overall amount of light received, reduce the aging speed, and delay aging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

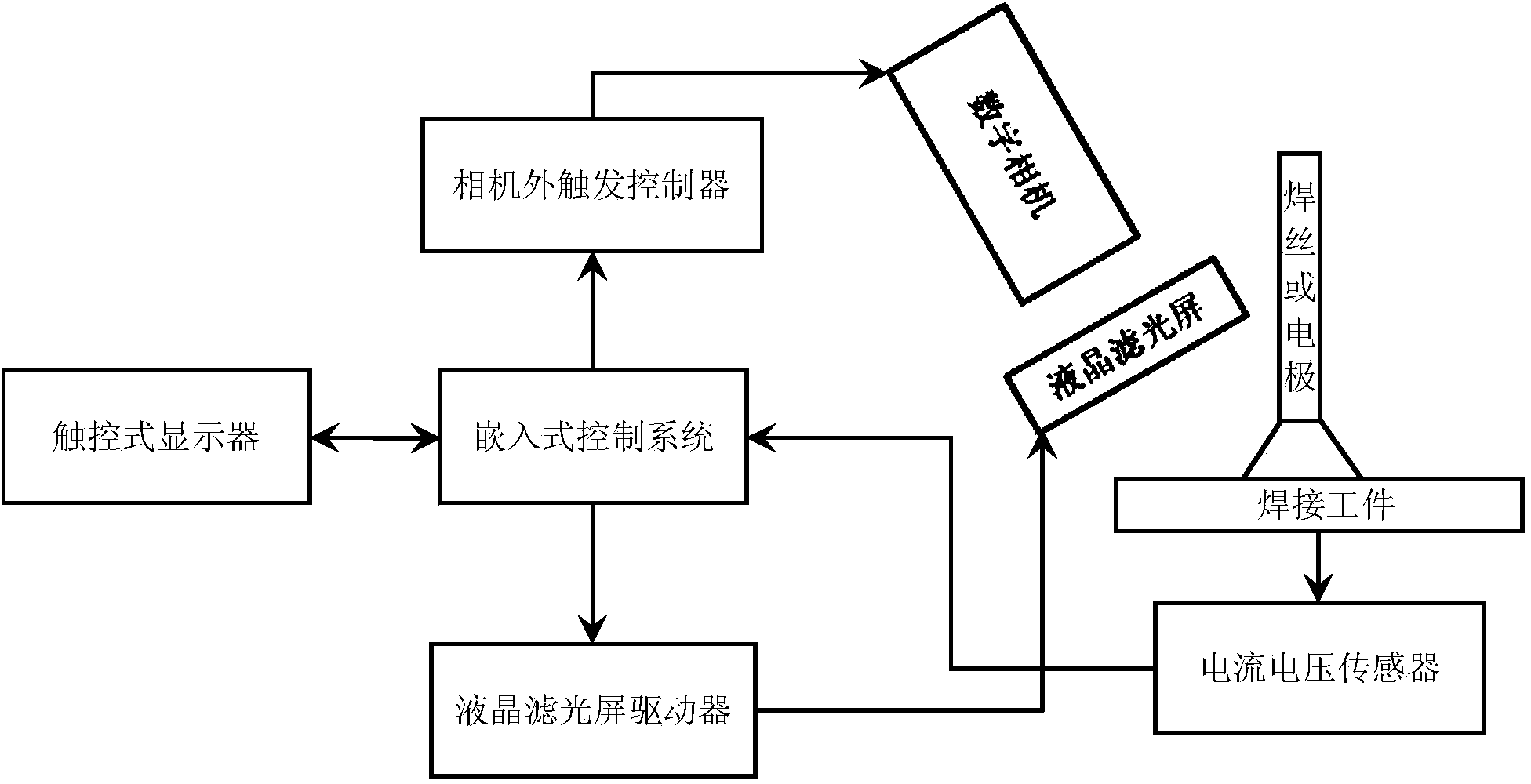

[0019] Schematic diagram of the system and how to use it figure 1 As shown, the control part of the system is an embedded system, which is connected with current and voltage sensors, touch screen, LCD filter screen driver and camera external trigger driver. The current and voltage sensor is responsible for collecting and transmitting the electrical parameter signals of the welding process. For the embedded control system, the touch screen is responsible for setting and displaying the parameters of the LCD filter screen, the electrical parameters of the welding process, the driver of the LCD filter screen is responsible for generating the driving signal of the LCD screen, and the external trigger driver of the camera is responsible for generating the camera frame trigger and exposure The time control signal; the LCD filter screen driver is connected with the LCD screen, and the LCD screen driving signal is transmitted to the LCD screen; the camera external trigger driver is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com