Multilayer composite insulation carpet for hot-line work and preparation method for multilayer composite insulation carpet

A technology of composite insulation and live work, applied in the field of rubber insulation blankets, can solve the problems of poor product softness, high scrap rate, and complex structure of insulation blankets, and achieve the advantages of convenient production, reduced scrap rate, and overcoming poor flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

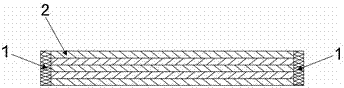

[0045] Example 1: figure 1 , figure 2An example of an insulation blanket composed of 5 rubber sheets is given. The thickness of each rubber sheet 2 is 0.7mm±0.2mm. Five rubber sheets are superimposed on a semi-finished product with a thickness of 3.7mm, and the semi-finished product is put into the mold. Then it is vulcanized by a flat vulcanizer, and the reinforcement edge 1 is formed by pressing the surrounding sides of the vulcanization; the width of the reinforcement edge 1 around the insulation blanket is 6mm, and the reinforcement edge 1 and the overall insulation blanket are both planar structures (the existing multi-layer rubber composite insulation blanket The edge is 6mm wide and 8mm thick, and the edge is higher than the overall insulation blanket. The maximum width of the arc on the edge is 16mm, and the thickness is 8mm, that is, the arc is higher than the edge). Compared with existing products, the peripheral structure of the insulating blanket is obviously sim...

Embodiment 2

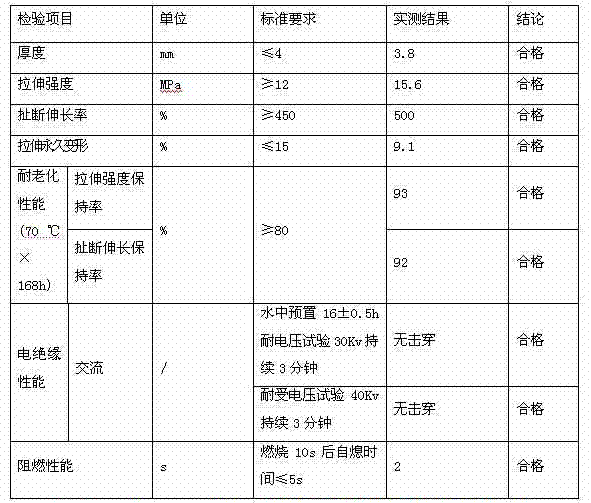

[0081] Example 2: The thickness of the rubber sheet is 0.9mm±0.2mm, and 4 sheets are stacked according to the requirements of the withstand voltage level, and a semi-finished product with a thickness of 3.8mm.

[0082] Each component of the rubber sheet in Example 2 was formulated according to the following weight (kg):

[0083] EPDM 50

[0084] Active agent zinc oxide 2.5

[0085] Active agent stearic acid 0.75

[0086] Active agent silicon-69 0.5

[0087] Accelerator M 0.45

[0088] Accelerator CZ 0.6

[0089] Vulcanizing agent sulfur 0.7

[0090] Reinforcing filler silica 10

[0091] Reinforcing filler Light calcium carbonate 7.5

[0092] Anti-scorch agent salicylic acid 0.15

[0093] Antiaging agent RD 0.5

[0094] softener transformer oil 2

[0095] Flame retardant decabromodiphenyl ether 4

[0096] Colorant Rubber Scarlet 0.75

[0097] The concrete preparation method of embodiment 2 comprises the steps:

[0098] Step 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com