Light heat-resisting conveyor belt

A heat-resistant conveyor belt, light-weight technology, applied in the field of conveyor belts, can solve the problems that heat-resistant conveyor belts cannot meet the energy-saving and environmental protection requirements of enterprises, increase replacement costs, increase energy consumption, etc., achieve light weight, high heat dissipation rate, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

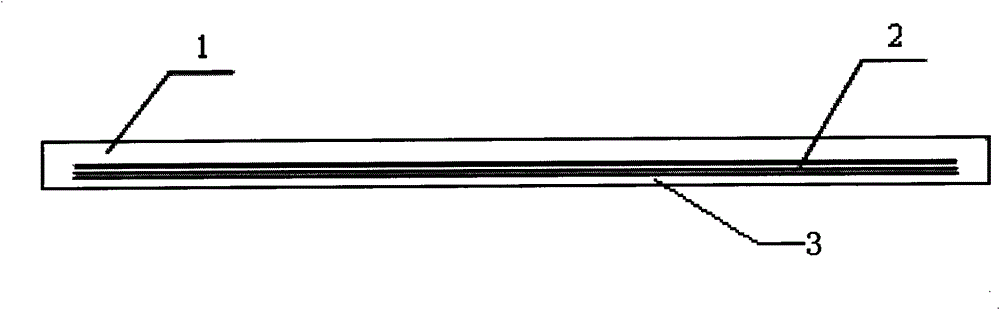

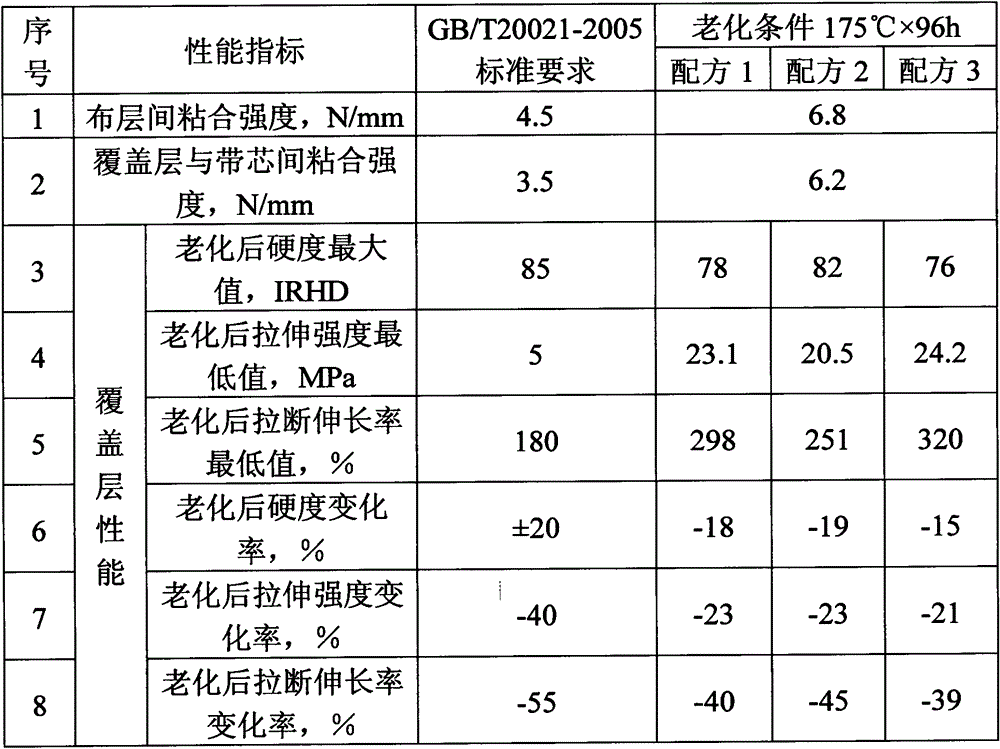

[0027] A light-duty heat-resistant conveyor belt, comprising an aramid canvas core, the aramid canvas core is a single-layer or multi-layer laminate with a heat-resistant adhesive layer coated on the surface of the aramid canvas core, and the upper and lower surfaces of the aramid canvas core are coated with Covered with a heat-resistant adhesive layer, the thickness of the heat-resistant adhesive layer is 0.45±0.02mm, the thickness of the upper heat-resistant adhesive layer of the heat-resistant adhesive layer is 5.0±0.2mm, and the lower heat-resistant adhesive layer The thickness is 1.5±0.1mm.

[0028] The formula of heat-resistant adhesive is as follows: 60 parts of EPDM rubber, 40 parts of natural rubber, 2 parts of sulfur, 2 parts of accelerator M, 2 parts of accelerator TMTD, 1 part of anti-aging agent RD, 2 parts of anti-aging agent BLE, 10 parts of zinc oxide, 1.5 parts of stearic acid, 20 parts of terpene resin, 30 parts of carbon black, 15 parts of white carbon black...

Embodiment 2

[0041] A light-duty heat-resistant conveyor belt, the formula of heat-resistant adhesive is as follows: 50 parts of EPDM rubber, 50 parts of natural rubber, 2.5 parts of sulfur, 4 parts of accelerator DM, 2 parts of anti-aging agent RD, 1 part of anti-aging agent, zinc oxide 5 parts, 1 part of stearic acid, 10 parts of terpene resin, 20 parts of carbon black, 10 parts of white carbon black, 5 parts of binder RS.

[0042] The preparation method of the heat-resistant adhesive layer is as in Example 1.

[0043] The formula of heat-resistant cover glue is as follows: 90 parts of EPDM, 10 parts of neoprene, 5 parts of zinc oxide, 1 part of stearic acid, 10 parts of light calcium carbonate, 7 parts of magnesium oxide, 5 parts of anti-aging agent BLE, paraffin wax 8 parts of oil, 5 parts of terpene resin, 40 parts of carbon black, 0.1 part of sulfur, 4 parts of vulcanizing agent DCP, 1 part of anti-fatigue agent PL-6001.

[0044] The preparation method of the heat-resistant cover gl...

Embodiment 3

[0046] A light heat-resistant conveyor belt, the formula of heat-resistant adhesive is as follows: 70 parts of EPDM rubber, 30 parts of natural rubber, 1.5 parts of sulfur, 3 parts of accelerator M, 2 parts of accelerator TMTD, 5 parts of anti-aging agent BLE, zinc oxide 15 parts, 2 parts of stearic acid, 25 parts of terpene resin, 40 parts of carbon black, 20 parts of white carbon black, 4 parts of binder RS, 3 parts of binder RH.

[0047] The preparation method of the heat-resistant adhesive layer is as in Example 1.

[0048] The formula of heat-resistant cover glue is as follows: 100 parts of EPDM, 10 parts of zinc oxide, 2 parts of stearic acid, 2 parts of magnesium oxide, 8 parts of anti-aging agent RD, 20 parts of paraffin oil, 10 parts of terpene resin, 60 parts of carbon black 0.5 parts of sulfur, 6 parts of vulcanizing agent DCP, 1 part of vulcanizing agent PDM, and 3 parts of anti-fatigue agent PL-6000.

[0049] The preparation method of the heat-resistant cover glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com