Pre-treatment system for kitchen waste water

A technology for kitchen waste and wastewater, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Water treatment effect, improvement of treatment effect, effect of mitigation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

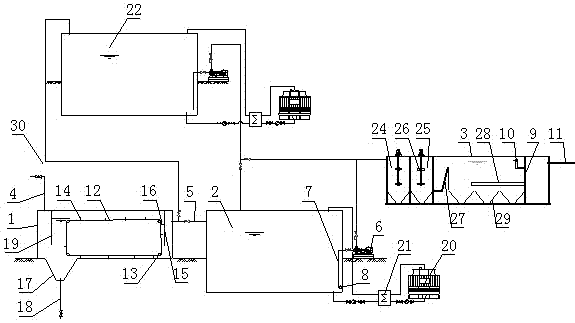

[0036] as follows figure 1 As shown, a food waste wastewater pretreatment system includes an oil-separating sedimentation tank 1, a regulating tank 2 and a demulsification coagulation air flotation and slag removal device. One end of the oil-separating sedimentation tank 1 is provided with a garbage fermentation wastewater inlet pipe 4. The other end is connected to the regulating tank 2 through the outlet pipe 5, and an oil slick removal device is arranged in the oil-separating sedimentation tank 1; One end is the water outlet and the water outlet is connected to the demulsification coagulation air flotation and slag removal device through the lifting pump 6 and the water outlet lifting pipeline 7. The water outlet of the regulating pool is also provided with a temperature probe 8 and an outlet water temperature control device. The position of the water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com