Preparation method and application of multifunctional vinyl polymer

A vinyl polymer, multifunctional technology, applied in the field of chemical products, can solve problems such as low efficiency, poor antibacterial effect, and human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

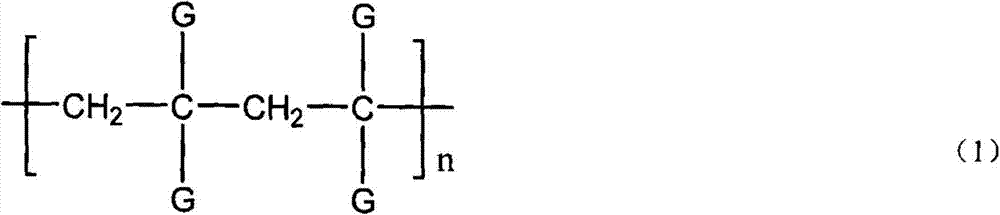

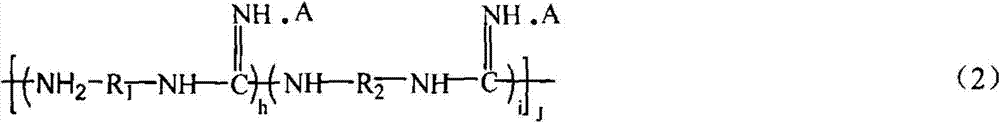

AI Technical Summary

Problems solved by technology

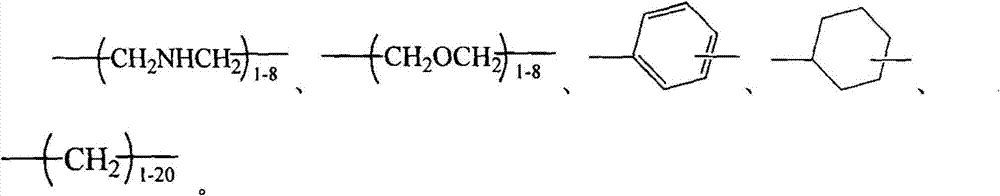

Method used

Image

Examples

Embodiment 1

[0055] Copolymerization of 1,6-hexanediamine, 1,10-decanediamine and guanidine phosphate was used to prepare two types of polyamines and guanidine salt cocondensation products (code A), and the multifunctional polypropylene was prepared by melting reaction method , and then added to the polypropylene matrix as a masterbatch to make polypropylene special material (No. 1#):

[0056] Take 58.1g of 1,6-hexanediamine, 86.15g of 1,10-decanediamine, and 108.07g of guanidine phosphate, add them into a 500ml three-necked flask, stir and raise the temperature to 110°C under the protection of nitrogen, and react for 1 hour. Then the temperature was raised to 185° C. to react for 8 hours, and finally poured out while hot to obtain the co-condensation polymer A of two types of polyamines and guanidinium salts.

[0057] Get 10 kilograms of polypropylene Y1600 (Jinshan Petrochemical, melt index 16.0g / 10min), 0.2 kilograms of maleic anhydride graft monomer, 0.2 kilograms of styrene, 36 grams ...

Embodiment 2

[0061] Copolymerization of 1,6-hexamethylenediamine, ethylenediamine and guanidine phosphate was used to prepare two types of polyamine and guanidine salt cocondensation (code B), and the method of melting reaction was used to prepare multifunctional polypropylene, and then used as the parent The material is added to the polypropylene matrix to make a special material for polypropylene (No. 2#):

[0062] The synthesis method of the cocondensation polymer B of two types of polyamines and guanidine salts is the same as in Example 1, except that 30.06 g of ethylenediamine is substituted for 1,10-decanediamine for copolymerization to obtain two types of polyamines and guanidine salts Salt cocondensation polymer B. Its reaction with the functionalized polypropylene prepared in Example 1 is also exactly the same as in Example 1, and the grafting efficiency of the prepared functionalized polypropylene is listed in Table 1. The preparation method of 2# polypropylene special material ...

Embodiment 3

[0064] Copolymerization of 1,6-hexamethylenediamine, p-phenylenediamine and guanidine phosphate was used to prepare two types of polyamines and guanidine salt cocondensation (code C), and the method of melting reaction was used to prepare multifunctional polypropylene, and then used as The masterbatch is added to the polypropylene matrix to make polypropylene special material (No. 3#):

[0065] The synthesis method of the cocondensation polymer C of two types of polyamines and guanidine salts is the same as in Example 1, except that 54.07 g of p-phenylenediamine is replaced by 1,10-decanediamine for copolymerization reaction to obtain two types of polyamines and Cocondensate C of guanidinium salt. Its reaction with the functionalized polypropylene prepared in Example 1 is also exactly the same as in Example 1, and the grafting efficiency of the prepared functionalized polypropylene is listed in Table 1. The preparation method of 3# polypropylene special material is also exact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com