High-moisture-retention VOC-free iron oxide color paste and preparation method thereof

A technology of iron oxide and color paste, applied in the direction of pigment paste, etc., can solve the problems of unable to meet their own health and environmental protection requirements, unable to meet market demand, poor moisture retention and stability, etc., to achieve convenient production, easy operation and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

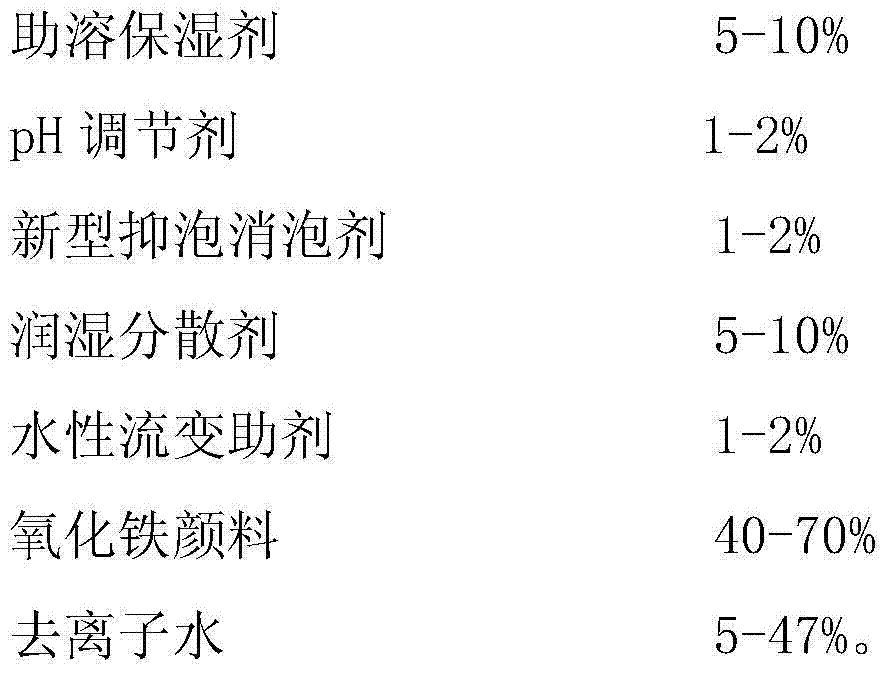

[0022] Step 1): Mix 10% solubilizing moisturizing agent: polyethylene glycol, 1% pH regulator: ammonia water, 1% new anti-foaming and defoaming agent: polysiloxane, 10% wetting and dispersing agent by weight percentage: Mix fatty acids and 27% deionized water;

[0023] Step 2): Slowly add 50% iron oxide red pigment to the mixed liquid obtained in step 1) for high-speed dispersion, and form a uniform slurry dispersion under high-speed stirring;

[0024] Step 3): Use a pump to input the slurry dispersion into the bead mill for grinding and dispersing for 2 to 5 times, until the fineness of the slurry dispersion is less than 2 μm, then stop grinding;

[0025] Step 4): Add 1% water-based rheology additive to the ground slurry dispersion, adjust the viscosity range to 70-85KU, and obtain iron oxide red ultra-fine water-based color paste dispersion.

[0026] Under the premise of ensuring other performances, the iron oxide red slurry obtained in the present invention has a VOC conte...

Embodiment 2

[0028] Step 1): 10% solubilizing and moisturizing agent: polypropylene glycol, 1% pH regulator: urea, 1% new anti-foaming and defoaming agent: silicone mineral oil, 10% wetting and dispersing agent: aliphatic Mix amides and 36% deionized water;

[0029] Step 2): Slowly add 40% iron oxide red pigment for high-speed dispersion, and form a uniform slurry dispersion under high-speed stirring;

[0030] Step 3): Use a pump to input the slurry dispersion into the bead mill for grinding and dispersing for 2 to 5 times, until the fineness of the slurry dispersion is less than 2 μm, then stop grinding;

[0031] Step 4): Add 2% water-based rheology additive to the ground slurry dispersion, adjust the viscosity range to 70-85KU, and obtain iron oxide red ultra-fine water-based color paste dispersion.

[0032] Under the premise of ensuring other performances, the iron oxide red slurry obtained in the present invention has a VOC content of N.D. and an APEO of 80PPM, meeting the standards o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com