Ash cleaning device for ferroalloy submerged arc furnace waste heat boiler

A waste heat boiler and ash cleaning device technology, which is applied in the fields of solid residue removal, lighting and heating equipment, combustion product treatment, etc., can solve the problem of different anti-fatigue life, great difference in dust removal effect, and ash enrichment in the bead ash separation section and other problems, to achieve the effect of strong intermolecular adsorption, remarkable cleaning effect and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

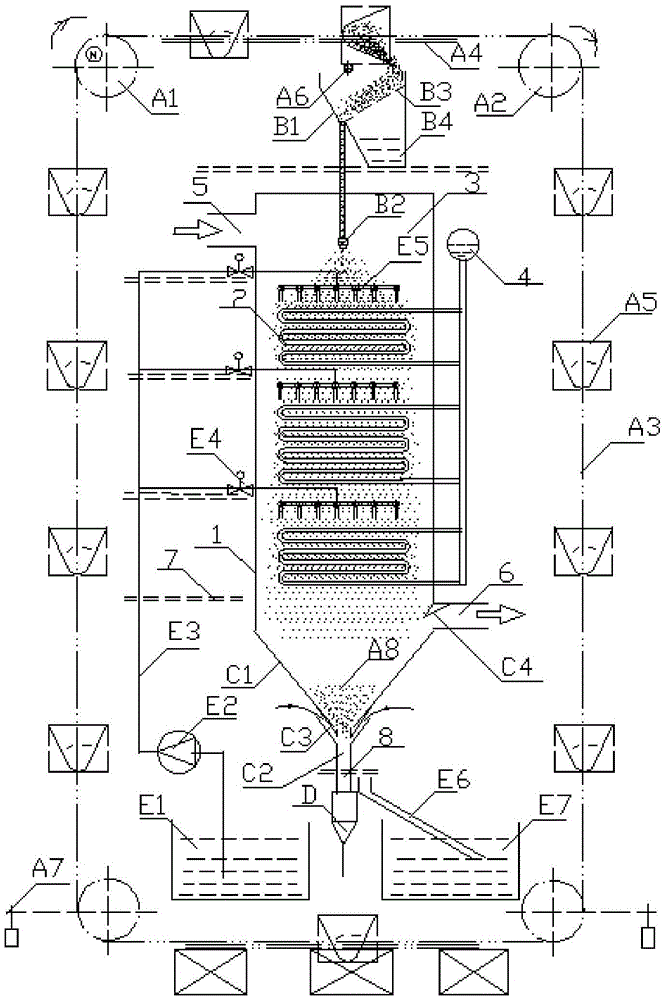

[0024] Such as figure 1 As shown, the present invention is mainly composed of three interrelated three major parts: a waste heat boiler, a steel ball ash removal device and a solution cleaning device.

[0025] Waste heat boiler: including shell 1, serpentine heat exchange tube 2, convection shaft 3, drum 4, flue gas inlet 5, flue gas outlet 6, bracket 7 and flange 8. Support 7 is a frame made of columns and beams. A drum 4 is provided on the support 7 , and a convection shaft 3 is provided inside the support 7 , and the convection shaft 3 is composed of a shell 1 , a flue gas inlet 5 and a flue gas outlet 6 . Among them, the shell 1 of the convection shaft 3 is the furnace wall, that is, the inner and outer guard plates are provided with insulation materials, such as calcium silicate board, aluminum silicate fiber felt or rock wool, etc., and the inner guard plate faces the inner side of the furnace wall. Features refractory concrete. One end of the convection shaft casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com