Method and device for defrosting through combination operation of multiple air heat source heat exchangers

An air heat exchanger and heat exchanger technology, applied in refrigeration and liquefaction, lighting and heating equipment, damage protection, etc., can solve the problems of fins affecting heat exchange effect, air side fin corrosion, affecting the surrounding environment, etc. Achieve the effect of simple installation, high energy efficiency ratio and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

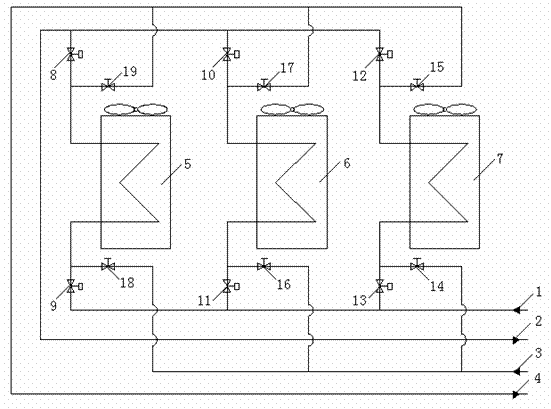

[0057] With reference to the accompanying drawings, the multi-air heat source heat exchanger combined defrosting device of the present embodiment includes No. 1 air heat exchanger 5, No. 2 air heat exchanger 6, and No. 3 air heat exchanger 7. The No. 1 air heat exchanger The inlet of the heat exchanger 5 is provided with two branch pipes, one branch pipe is equipped with an electronic valve I9, and is connected to the evaporator outlet of the main unit of the workstation through the pipe I1, and the other branch pipe is equipped with an electronic valve II18, and through the pipe Road III3 is connected to the condenser outlet of the workstation host, and the outlet of the No. 1 air heat exchanger 5 is provided with two branch pipes, one of which is equipped with an electronic valve III8, and is connected to the evaporator of the workstation hos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com