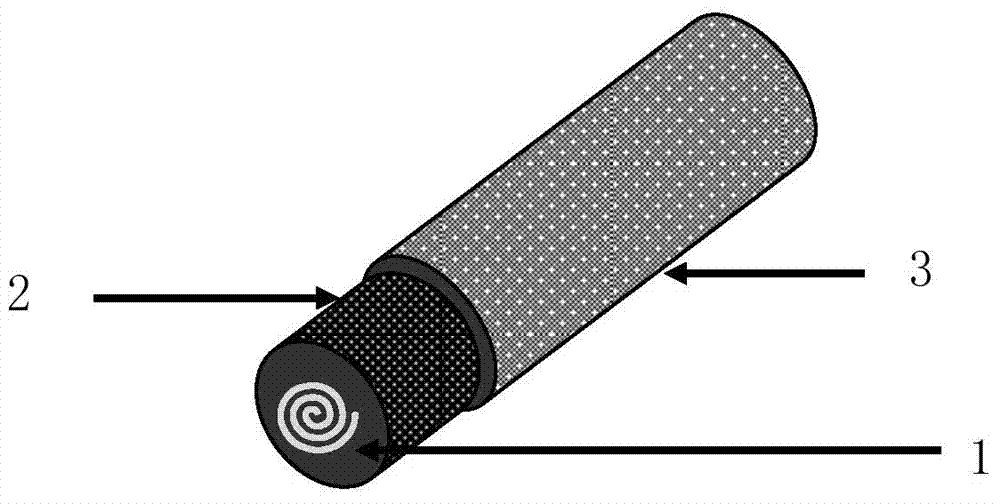

Full-carbon coaxial line and manufacturing method thereof

A technology of coaxial line and inner conductor, applied in the direction of carbon-silicon compound conductor, waveguide, electrical components, etc., can solve the problems of circuit RC delay, increase of total resistance of transmission line, concave surface of conductor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below by example. It should be noted that the purpose of the disclosed embodiments is to help further understand the present invention, but those skilled in the art can understand that various replacements and modifications are possible without departing from the spirit and scope of the present invention and the appended claims of. Therefore, the present invention should not be limited to the content disclosed in the embodiments, and the protection scope of the present invention is subject to the scope defined in the claims.

[0020] Single-layer, double-layer, and multi-layer graphene can be used. The specific preparation process of the graphene-based all-carbon coaxial line is as follows:

[0021] (1) Preparation of carbon-based materials: Obtaining the required graphene (single layer, double layer, multilayer or graphite sheet) can be achieved by various methods, for example: mechanical exfoliation, chemical vapor dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com