Biscuit containing dietary fiber and preparation method of biscuit

A technology for dietary fiber and biscuits, applied in the field of biscuits, can solve the problems of rough taste, difficult processing, difficult water solubility, etc., and achieve the effect of improving taste and good health care effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

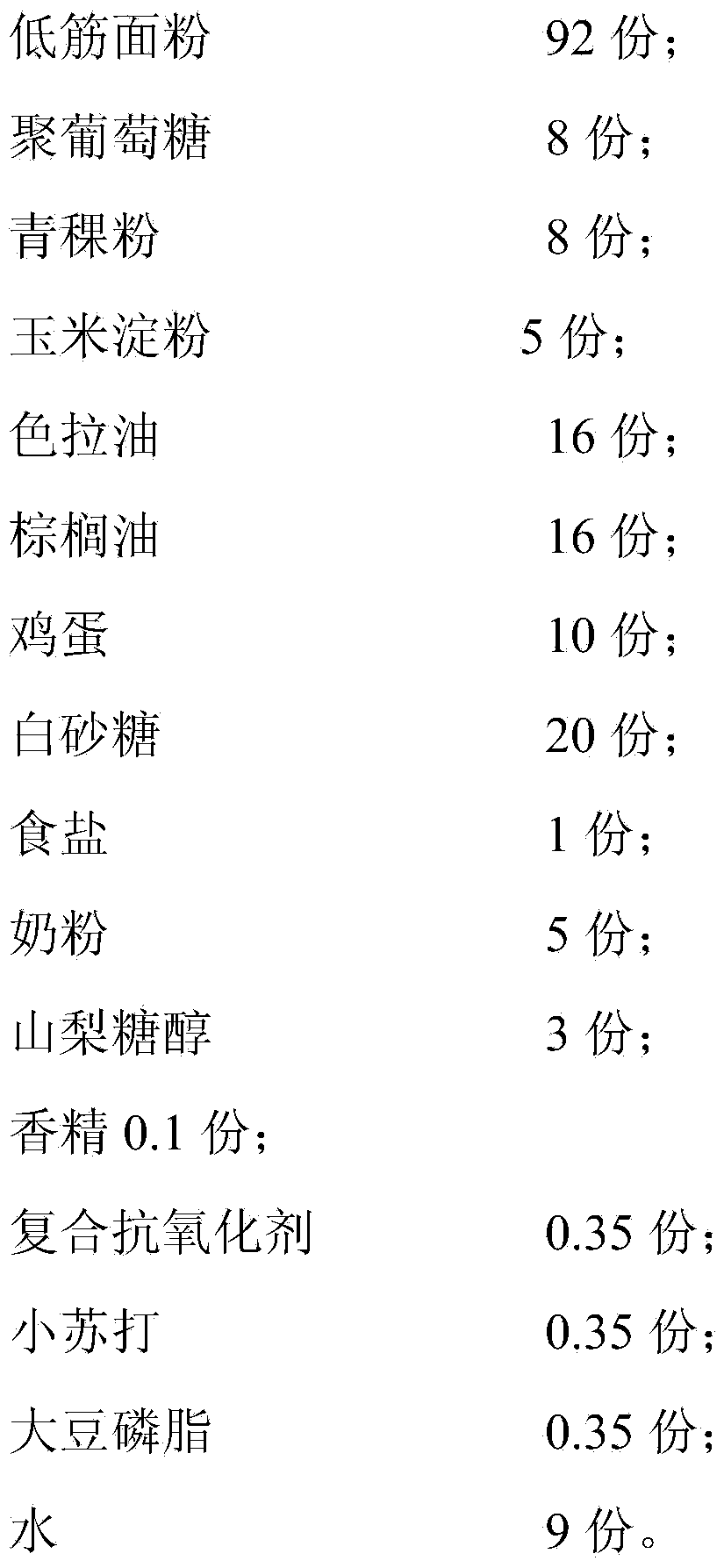

[0022] Embodiment 1: Weigh each raw material component according to the following mass ratio.

[0023]

[0024]

[0025] Put the other raw material components except the sifted high-gluten flour and low-gluten flour, ground white sugar, cornstarch and water into the powder mixer and stir evenly. Stir vigorously at high speed for 10 minutes, pour high-gluten flour, low All-purpose flour, white granulated sugar, cornstarch and water, continue to adjust the flour for 20 minutes until a smooth and soft dough is formed, and the dough should have moderate elasticity, good extensibility, non-stickiness and moderate plasticity. Next, the dough is rolled through 9 to 13 stages, and the rolling ratio during the rolling process is not more than 1:3, and finally a smooth dough sheet with a thickness of 2mm is formed. The dough sheet is molded by roll printing to obtain a dough cake. Then, after baking the noodle cake at 240°C for 5 minutes, cool it until the center temperature is l...

Embodiment 2

[0026] Embodiment 2: Weigh each raw material component according to the following mass ratio.

[0027]

[0028]

[0029] Put the other raw material components except the sifted high-gluten flour and low-gluten flour, ground white sugar, cornstarch and water into the powder mixer and stir evenly, stir vigorously at high speed for 12 minutes, pour in high-gluten flour, low-gluten All-purpose flour, white granulated sugar, corn starch and water, continue to adjust the flour for 30 minutes until a smooth and soft dough is formed, and the dough should have moderate elasticity, good extensibility, non-stickiness and moderate plasticity. Next, the dough is rolled through 9 to 13 stages, and the rolling ratio during the rolling process is not more than 1:3, and finally a smooth dough sheet with a thickness of 3mm is formed. The dough sheet is molded by roll printing to obtain a dough cake. Then, after baking the noodle cake at 250°C for 3 minutes, cool it until the center tempe...

Embodiment 3

[0030] Embodiment 3: Weigh each raw material component according to the following mass ratio.

[0031]

[0032]

[0033] Put the other raw material components except the sifted high-gluten flour and low-gluten flour, ground white sugar, cornstarch and water into the powder mixer and stir evenly, stir vigorously at high speed for 11 minutes, pour in high-gluten flour, low All-purpose flour, white granulated sugar, corn starch and water, continue to adjust the flour for 25 minutes until a smooth and soft dough is formed, and the dough should have moderate elasticity, good extensibility, non-stickiness and moderate plasticity. Next, the dough is rolled through 9 to 13 stages, and the rolling ratio during the rolling process is not more than 1:3, and finally a smooth dough sheet with a thickness of 2.5mm is formed. The dough sheet is molded by roll printing to obtain a dough cake. Then, after baking the noodle cake at 245°C for 4 minutes, cool it until the center temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com