Preparation method for steady-state soybean lecithin

A technology of soybean lecithin and stabilization, which is applied in the directions of edible phospholipid composition, food science, protein food ingredients, etc., to achieve the effects of good water solubility, convenient product separation and high water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

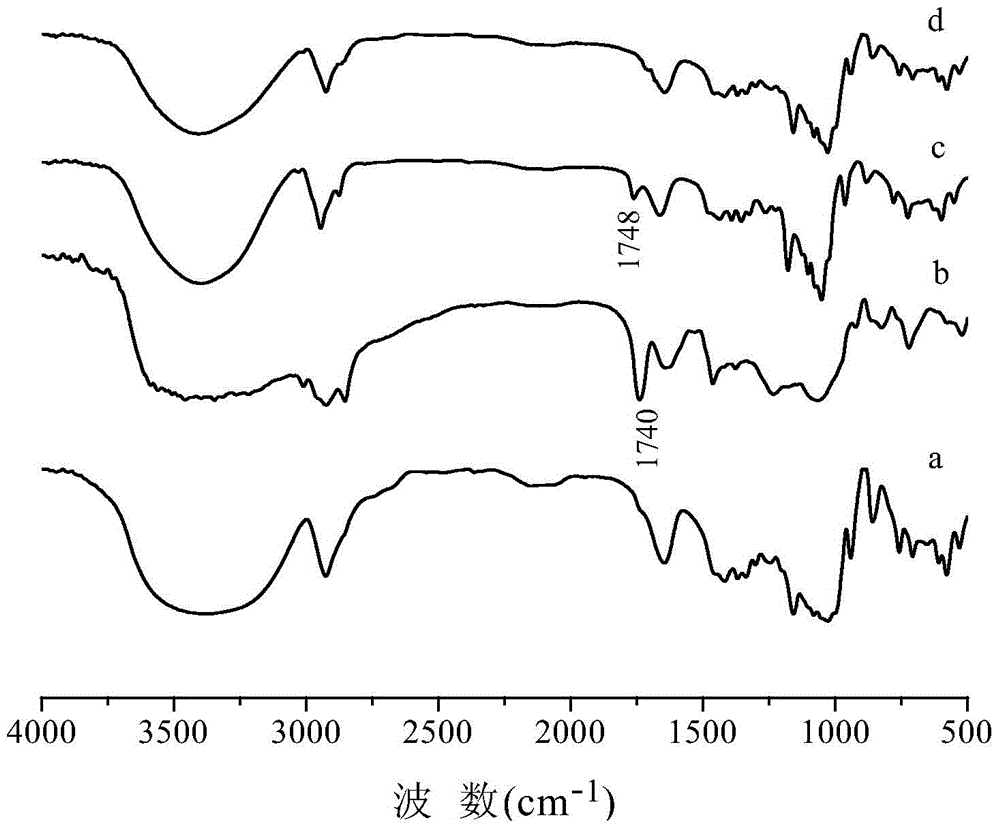

Image

Examples

Embodiment 1

[0022] The first step is to accurately weigh 18.07g of hydroxypropyl-β-cyclodextrin, add 36.14g of distilled water and stir to dissolve, and prepare a hydroxypropyl-β-cyclodextrin solution.

[0023] The second step is to accurately weigh 5g of soybean lecithin, add 85mL of absolute ethanol and stir to dissolve.

[0024] In the third step, slowly drop the soybean lecithin solution obtained in step (2) into the hydroxypropyl-β-cyclodextrin solution obtained in step (1), and stir and react at 60°C for 3 hours.

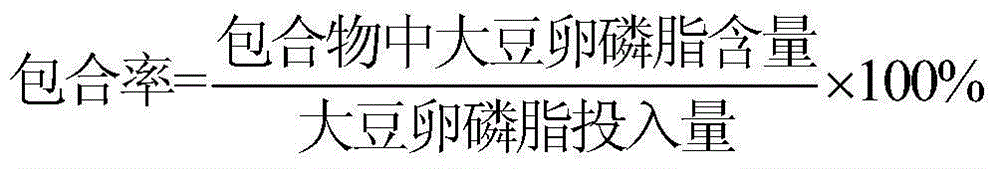

[0025] The fourth step is to cool the solution obtained in step (3) to room temperature, let it stand for 12 hours, filter it with suction, vacuum freeze-dry the filtrate, and pulverize it to obtain the inclusion compound of hydroxypropyl-β-cyclodextrin / soybean lecithin. The clathrate rate of the clathrate obtained was 54.8%.

[0026] Ultraviolet spectrophotometry is a common method for determination of inclusion rate. The specific determination method is: accurately wei...

Embodiment 2

[0038] The first step is to accurately weigh 4.52g of hydroxypropyl-β-cyclodextrin, add 22.6g of distilled water and stir to dissolve, and prepare a hydroxypropyl-β-cyclodextrin solution.

[0039]The second step is to accurately weigh 5g of soybean lecithin, add 50mL of absolute ethanol and stir to dissolve.

[0040] In the third step, the soybean lecithin solution obtained in step (2) is slowly added dropwise to the hydroxypropyl-β-cyclodextrin solution obtained in step (1), and the reaction is stirred at 50°C for 4 hours.

[0041] The fourth step is to cool the solution obtained in step (3) to room temperature, let it stand for 24 hours, filter it with suction, vacuum freeze-dry the filtrate, and pulverize it to obtain the inclusion compound of hydroxypropyl-β-cyclodextrin / soybean lecithin. The inclusion rate of the obtained clathrate was 34.3%.

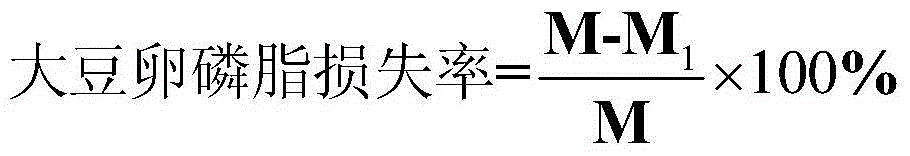

[0042] The thermal stability test results are as follows, the loss rates of clathrate and soybean lecithin at 40°C are 19.4%, 52...

Embodiment 3

[0044] The first step is to accurately weigh 36.12g of hydroxypropyl-β-cyclodextrin, add 108.36g of distilled water and stir to dissolve, and prepare a hydroxypropyl-β-cyclodextrin solution.

[0045] The second step is to accurately weigh 5g of soybean lecithin, add 75mL of absolute ethanol and stir to dissolve.

[0046] In the third step, slowly drop the soybean lecithin solution obtained in step (2) into the hydroxypropyl-β-cyclodextrin solution obtained in step (1), and stir and react at 50°C for 3 hours.

[0047] The fourth step is to cool the solution obtained in step (3) to room temperature, let it stand for 36 hours, filter it with suction, vacuum freeze-dry the filtrate, and pulverize it to obtain the inclusion compound of hydroxypropyl-β-cyclodextrin / soybean lecithin. The inclusion rate of the obtained clathrate was 48.5%.

[0048] The thermal stability test results are as follows, the loss rates of clathrate and soybean lecithin at 40°C are 17.4%, 52.8%, respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com