Arsenic-fixing agent and preparation method thereof, and method utilizing arsenic-fixing agent to fix arsenic

A technology for fixing arsenic and metal salts, which is applied in the field of environmental governance, can solve the problems of unreported arsenic solidification rate, etc., achieve good economic and environmental comprehensive benefits, large porosity and specific surface area, and simple preparation and application methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In order to improve the arsenic solidification efficiency of calcium matrix materials, the porosity and specific surface area of traditional calcium matrix are improved by modification, and the activity of calcium ions is increased to further improve the arsenic fixation efficiency. In this embodiment, the calcium carbonate is prepared by adding different metal salts, and the arsenic-fixing agent with the best arsenic-fixing effect is obtained by constantly changing the types and blending ratios of the metal salts.

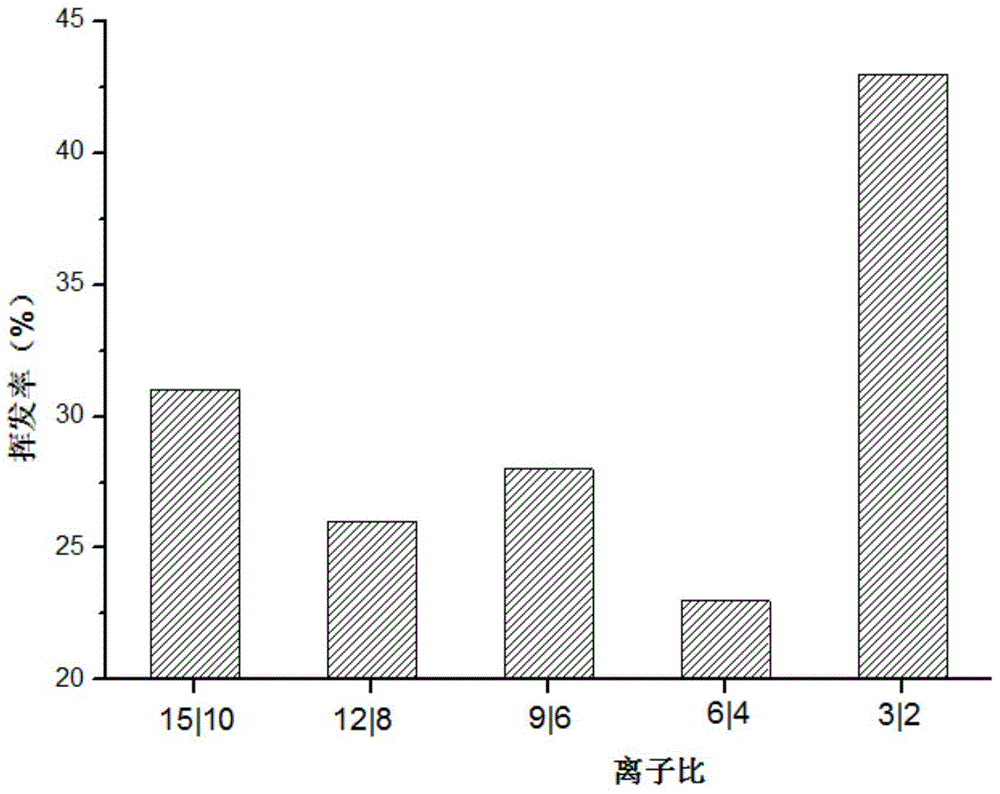

[0027] The present embodiment is studied by orthogonal experiments, and the adopted factors are respectively: the type of metal salt and its ion ratio γ (the ion ratio referred to in the present invention represents Ca 2+ / molar ratio of other metal salt ions) and combustion temperature on the arsenic fixation rate. Metal salt choose Na 2 CO 3 、K 2 CO 3 and Al 2 (SO 4 ) 3 , the combustion temperature of the orthogonal experiment is selected from t...

Embodiment 2

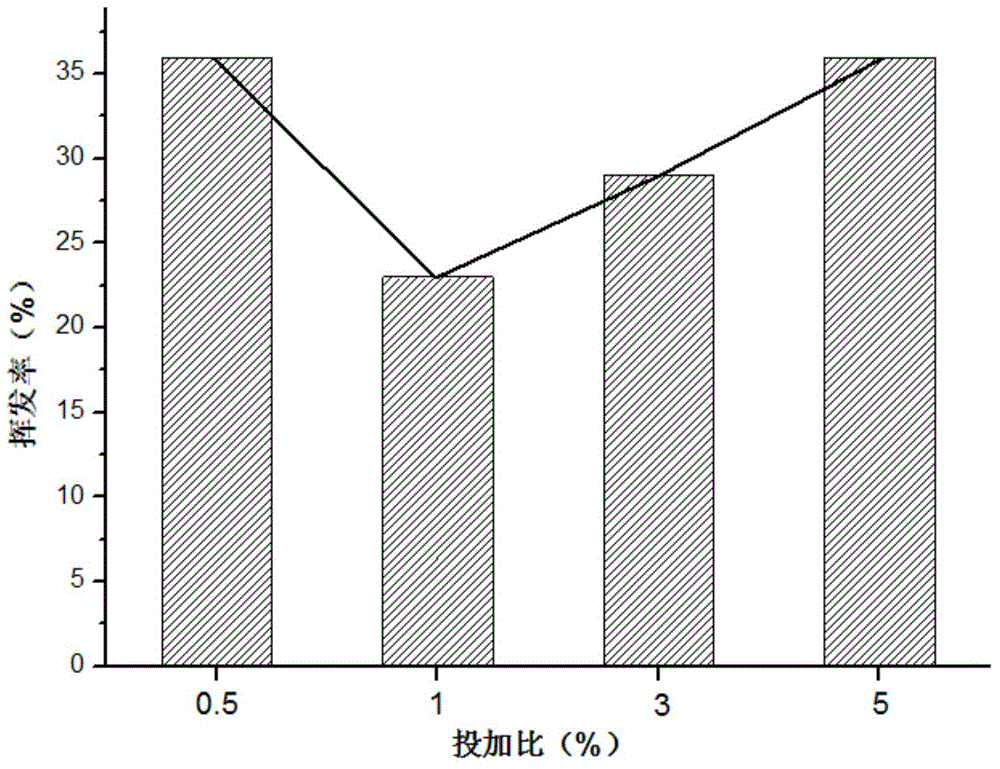

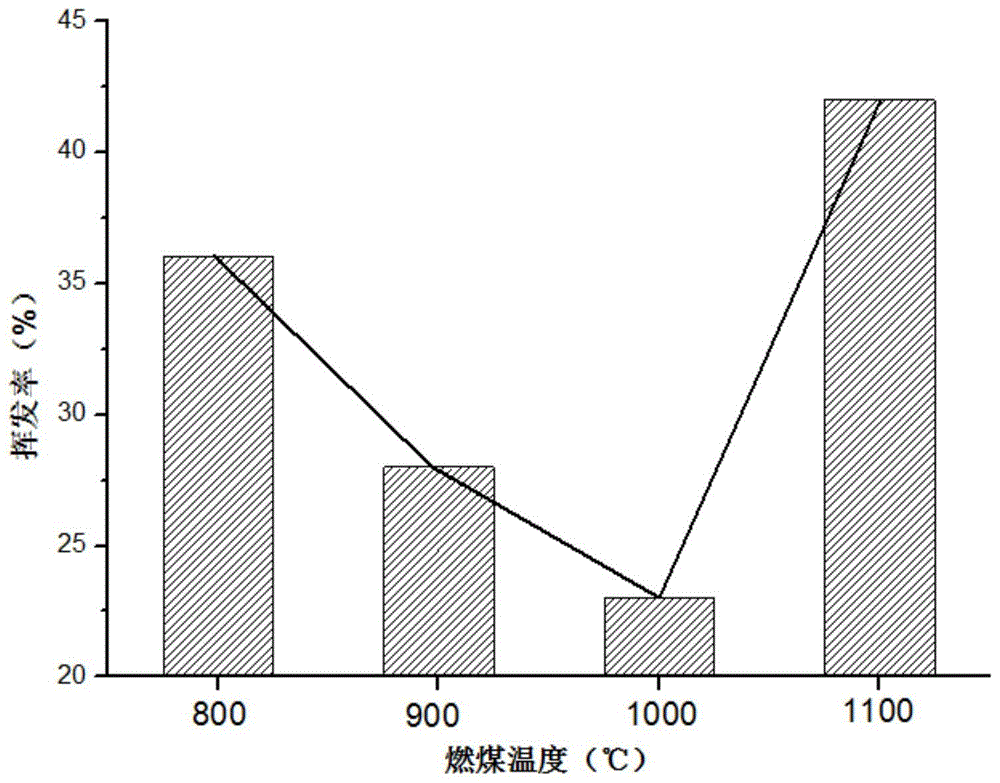

[0047] Two-factor analysis of variance experiments were designed with temperature and calcium carbonate addition as two factors in the experiment. Among them, the dosing ratio (λ) refers to the mass percentage (%) of the added arsenic fixation agent and raw coal, and there is no interaction between the two factors of temperature and dosing ratio. According to the research on the arsenic fixation of calcium matrix materials in the prior art, it is found that the coal combustion temperature has a significant effect on the arsenic fixation effect, and the effect is generally best at 900°C to 1100°C. In view of the safe operating temperature of the fluidized bed, the combustion temperature is set at four levels: 800°C, 900°C, 1000 and 1100°C. At the same time, the dosing ratio of arsenic-fixing agent was designed to be 0.5%, 1%, 3% and 5%, and one experiment was done for each level of combination. Then carry out the arsenic fixation experiment according to the method of Example 1...

Embodiment 3

[0052] Analysis of melting characteristics and surface characteristics of arsenic-fixing agent coal samples

[0053] The pretreated coal samples were taken without adding arsenic-fixing agent and adding arsenic-fixing agent with a dosage of 1% (Ca 2+ :Al 3+ : Na + :K + The ion ratio is equal to 1: (1 / 15): (1 / 6): (1 / 4)), then fully burn in the muffle furnace and then observe the weight loss of the coal sample, and draw the TG-DSC curve according to the weight loss. The TG-DSC curve of the unreinforced arsenic coal sample is as follows Figure 4 Shown, its characteristic peak is shown in table 6. The TG-DSC curve of arsenic-fixed coal sample is as follows Figure 5 Shown, its characteristic peak is as shown in table 7.

[0054] Table 6. Characteristic peaks of TG-DSC curves of unreinforced arsenic coal samples

[0055]

[0056] Depend on Figure 4 It can be seen from Table 6 that there is an obvious weight loss zone in the combustion process, and the temperature range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com