Hydrogenation upgrading catalyst carrier and preparation method thereof, hydrogenation upgrading catalyst using the carrier

A catalyst carrier, hydrogenation and upgrading technology, which is applied in the direction of catalyst carrier, organic compound/hydride/coordination complex catalyst, chemical instrument and method, etc., can solve the problems of easily polluting the environment, achieve low impurity content, reduce Pollution, effect of good floating dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

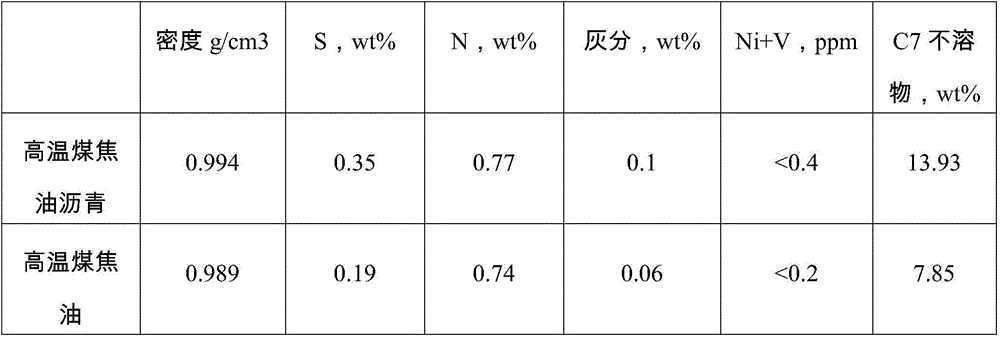

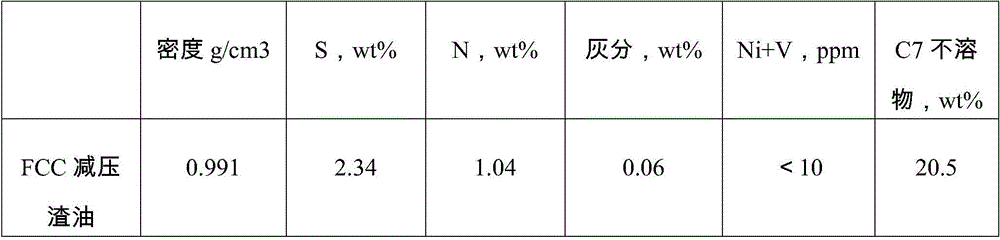

Embodiment 1

[0030] (1) Under normal pressure, mix 100Kg high-temperature coal tar with 200Kg quinoline and mix evenly at 80°C, then centrifuge at 80°C under a centrifugal force of 2000g to obtain insoluble matter;

[0031] (2) Wash 200 g of the above-mentioned insoluble matter with toluene 5 times, and then dry at 100° C. for 6 h to obtain a hydrogenation upgrading catalyst carrier A. The volume ratio of toluene to insoluble matter for each washing is 5:1.

Embodiment 2

[0033] (1) Under normal pressure, mix 100Kg high-temperature coal tar pitch with 400Kg anthracene oil and mix uniformly at 150°C, then filter and separate at 150°C to obtain insoluble matter;

[0034] (2) Wash 200 g of the above insoluble matter with crude benzene for 4 times, and then dry at 150° C. for 4 h to obtain the hydrogenation upgrading catalyst carrier B. The volume ratio of crude benzene to insoluble matter for each washing is 20:1.

Embodiment 3

[0036] (1) Under normal pressure, the mixture of 100Kg high-temperature coal tar and high-temperature coal tar pitch is mixed with 600Kg quinoline and mixed uniformly at 200°C, and then separated to obtain insolubles after standing and settling at 200°C; wherein, The mass ratio of the high-temperature coal tar and the high-temperature coal tar pitch can be any ratio, and in the present embodiment, the above-mentioned mass ratio is 1:1;

[0037] (2) Wash 200 g of the above-mentioned insoluble matter with light oil three times, and then dry at 200° C. for 3 h to obtain a hydrogenation upgrading catalyst carrier C. The volume ratio of light oil to insoluble matter for each washing is 40:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com