Jet liquid immersion ultrasonic detection method and liquid sprayer

A technology of ultrasonic detection and detection method, which is applied in the direction of spraying device, spraying device, measuring/indicating equipment, etc., which can solve the problems of poor measurement stability, restrained sound wave energy propagation, complex structure, etc., and achieve high liquid column stiffness and strong convergence ability , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

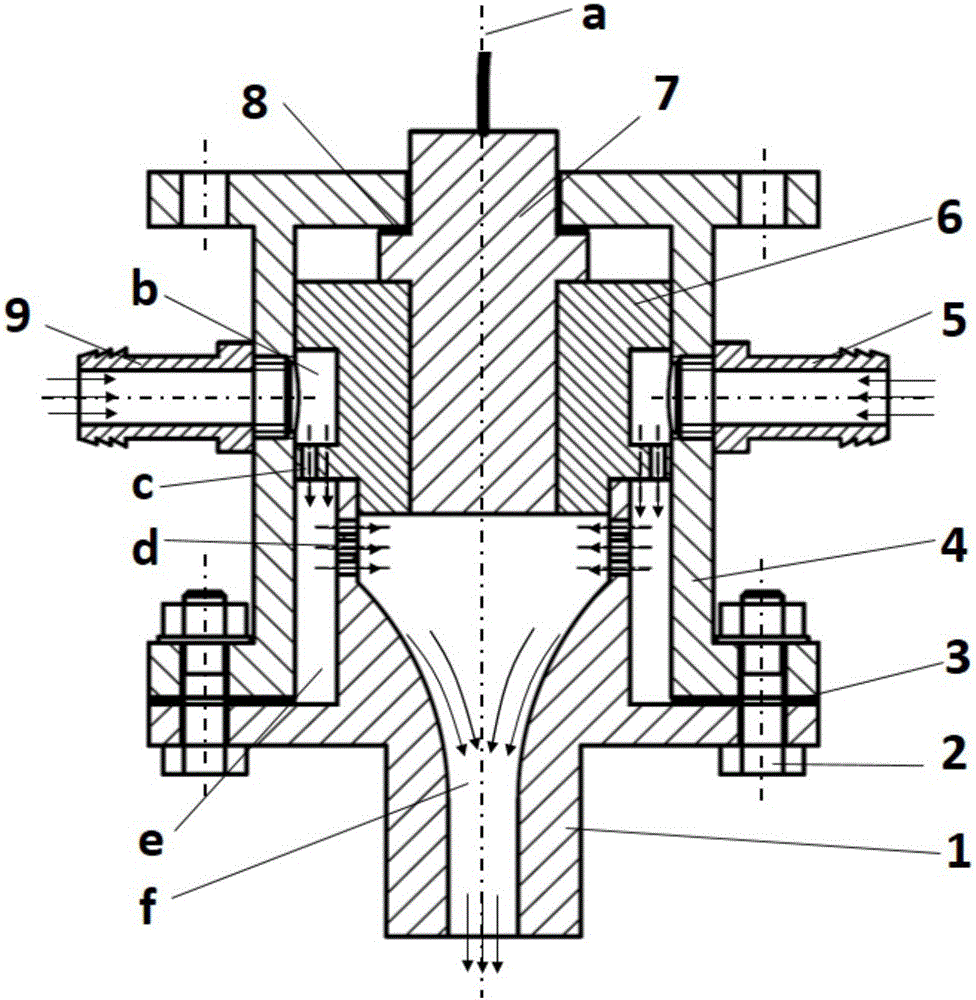

[0013] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings: first, the liquid sprayer 14 is connected to the spindle adapter mechanism 11 through four second bolt assemblies 13 evenly distributed in the circumferential direction, and then the spindle adapter mechanism 11 is installed on the machine tool spindle 10 , the numerical control machine tool automatically controls the liquid ejector 14 and the ultrasonic probe 7 to move according to the pre-designed measurement path, and measures the measured part 15, as shown in the appendix Figure 4 shown.

[0014] In order to realize the reliable detection of jet liquid immersion ultrasonic, the liquid jet 14 must meet the mixed constraints of the focused sound field geometry of the ultrasonic probe 6 and the state of the couplant flow field. Stable laminar flow field and rigid liquid column.

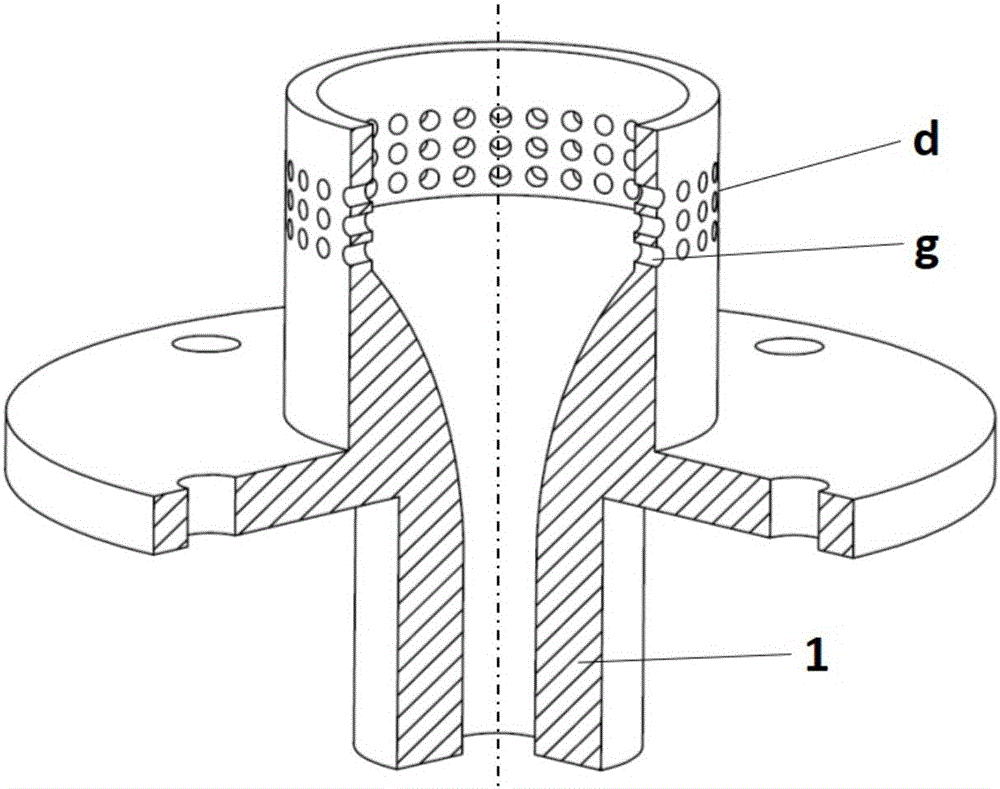

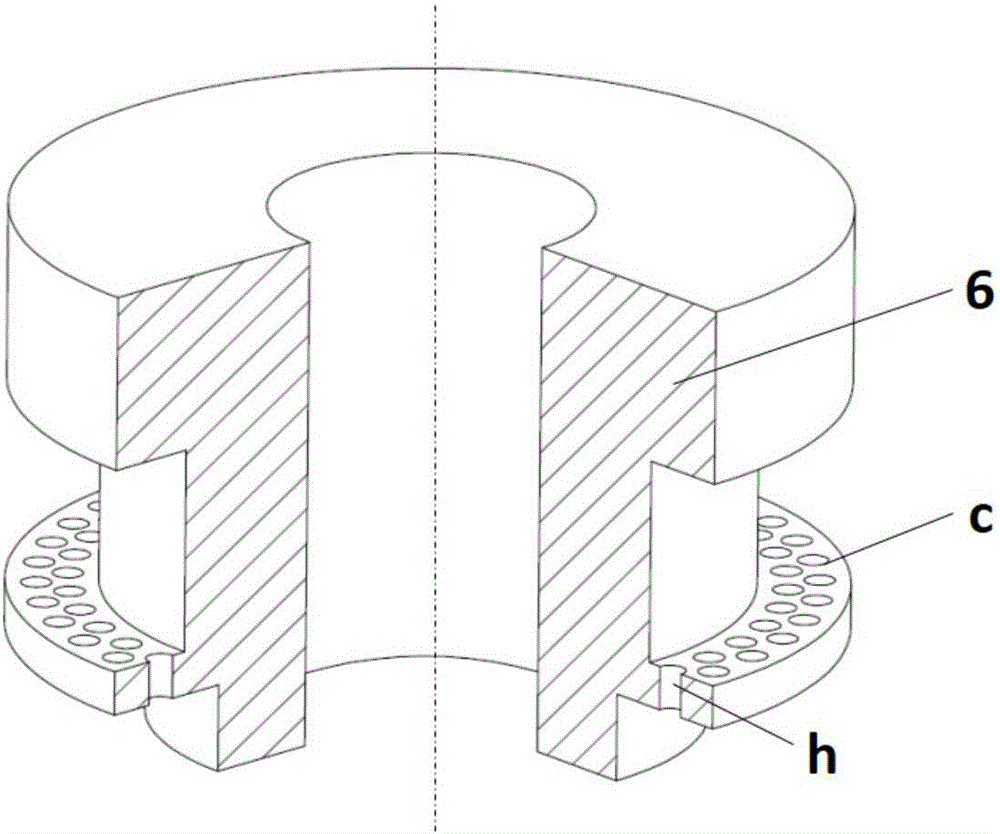

[0015] Liquid sprayer structure assembly: first, the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com