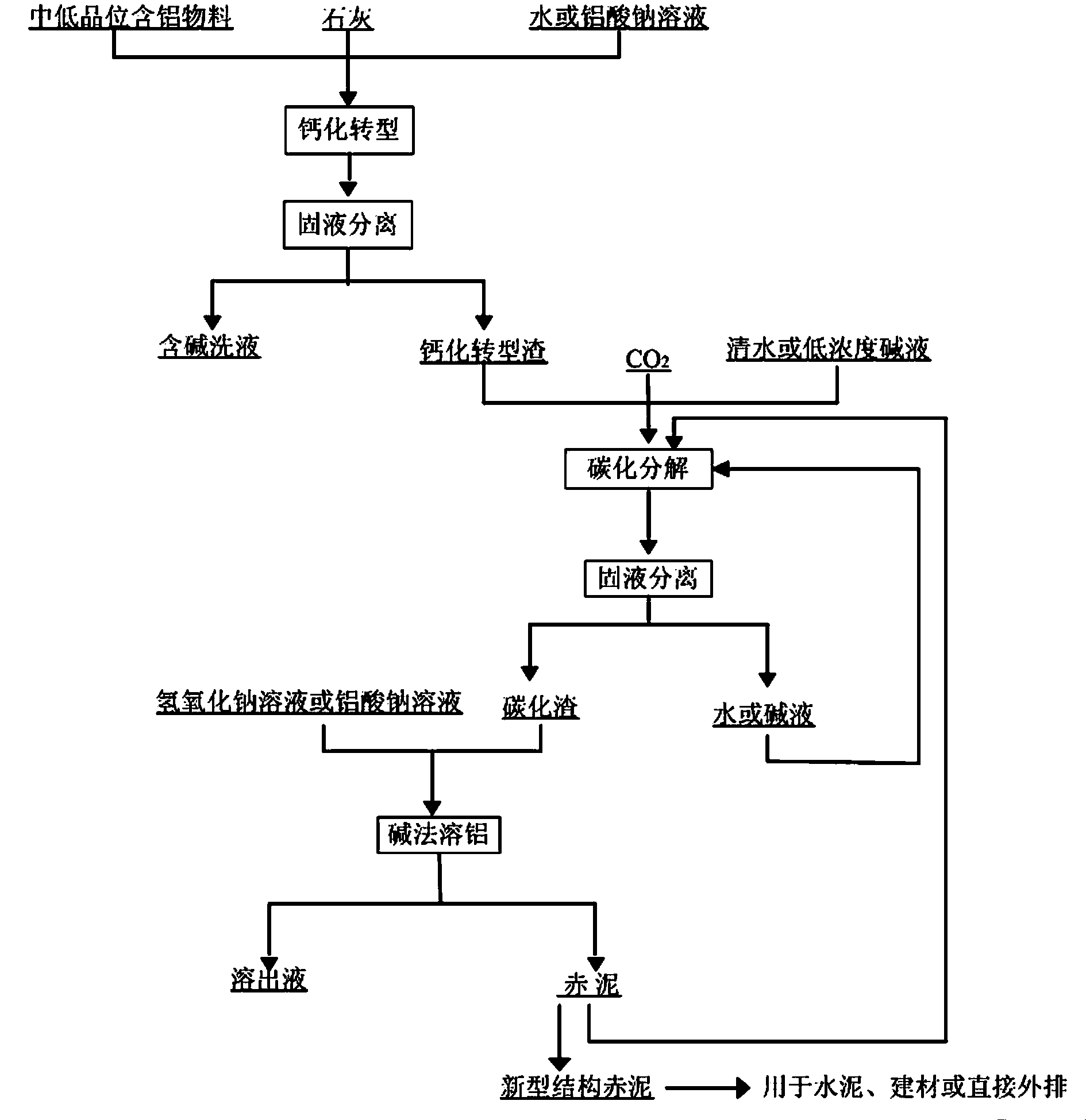

Method for reducing alumina-silica ratio of red mud through multistage carbonization

An aluminum-silicon ratio, red mud technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of a large amount of high-alkali red mud, increased alkali consumption, low alumina recovery rate, etc., and achieves low production energy consumption. , Low alkali content, and the effect of solving the environmental pollution caused by red mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Firstly, mix lime with medium and low-grade bauxite at a mass ratio of 0.25:1, and place them in a sodium aluminate solution with a caustic alkali concentration of 260g / L and a molar ratio of sodium oxide to aluminum oxide of 2.5 at 260°C Stirring and reacting for 15 minutes, a calcified transformation slag with hydrated calcium aluminosilicate as the main phase was obtained, and the liquid-solid ratio of the sodium aluminate solution to the solid material was 10ml:1 g;

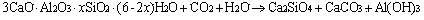

[0048] (2) Mix the calcified transformation slag and clean water in a closed container, and pass CO2 into the closed container 2 , CO 2 The gas partial pressure is 0.1MPa, and the reaction is stirred at 160°C for 240 minutes to obtain carbide slag containing calcium carbonate, hydrated calcium silicate, aluminum hydroxide and incompletely reacted hydrated calcium aluminosilicate, and a liquid-solid mixture of clean water and calcified transformation slag The ratio is 15ml: 1 g;

[0049] (3) Mix t...

Embodiment 2

[0052] (1) First mix lime and low-grade bauxite at a mass ratio of 0.35:1, and place them in a sodium aluminate solution with a caustic alkali concentration of 140g / L and a molar ratio of sodium oxide to aluminum oxide of 3.5 at 200°C Stirring and reacting for 60 minutes, a calcified transformation slag with hydrated calcium aluminosilicate as the main phase was obtained, and the liquid-solid ratio of the sodium aluminate solution to the solid material was 3ml: 1g;

[0053] (2) Mix the calcified transformation slag and clean water in a closed container, and pass CO2 into the closed container 2 , CO 2 The gas partial pressure is 1.6MPa, stirred and reacted at 60°C for 30 minutes, and the carbide slag containing calcium carbonate, hydrated calcium silicate, aluminum hydroxide and incompletely reacted hydrated calcium aluminosilicate is obtained, and the liquid-solid mixture of clear water and calcified transformation slag is obtained. The ratio is 3ml: 1 g;

[0054] (3) Mix th...

Embodiment 3

[0057] (1) Firstly, mix lime and medium-low-grade bauxite according to the mass ratio of 0.8:1, and put them in a sodium aluminate solution with a caustic alkali concentration of 180g / L and a molar ratio of sodium oxide to aluminum oxide of 3.0 at 100°C Stirring and reacting for 40 minutes, a calcified transformation slag with hydrated calcium aluminosilicate as the main phase was obtained, and the liquid-solid ratio of the sodium aluminate solution to the solid material was 5ml: 1g;

[0058] (2) Mix the calcified transformation slag and clean water in a closed container, and pass CO2 into the closed container 2 , CO 2 The gas partial pressure is 1.2MPa, and the reaction is stirred at 110°C for 120 minutes to obtain carbide slag containing calcium carbonate, hydrated calcium silicate, aluminum hydroxide and incompletely reacted hydrated calcium aluminosilicate, and a liquid-solid mixture of clean water and calcified transformation slag The ratio is 7ml: 1 g;

[0059] (3) Mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com