Combined surfactant and its preparation method

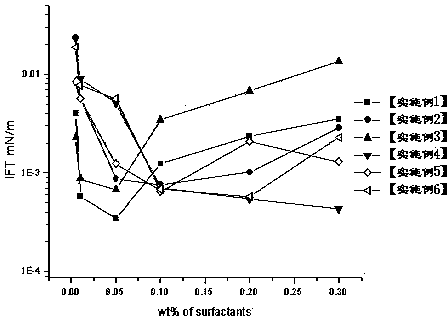

A technology of surfactant and active agent, applied in the field of combined surfactant and its preparation, can solve the problems of poor temperature resistance, low interfacial activity, unable to reach the interfacial tension value, etc., achieve excellent temperature resistance, increase hydrophilicity, etc. the effect of reducing the critical micelle concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

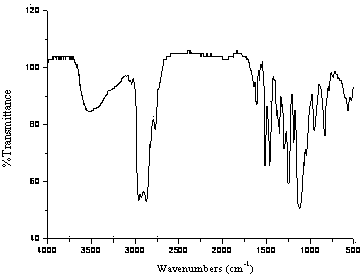

[0053] 1) Synthesis of nonylphenol polyoxypropylene polyoxyethylene ether betaine [a=8, b=2, R 2 =CH 3 , R 3 =CH 3 , R 4 =CH 2 CH(OH)CH 2 ,X - = SO 3 - ]

[0054] i. Add 463.2 g (0.6 mol) of nonylphenol polyoxypropylene polyoxyethylene ether (a=8, b=2) and thionyl chloride into a dry four-necked reaction flask equipped with stirring, condensation and tail gas absorption devices 107.1 grams (0.9 mole), heated to reflux, kept reflux reaction for 6 hours, after the reaction was completed, the distillation device was changed to distill off excess thionyl chloride to obtain chlorinated nonylphenol polyoxypropylene polyoxyethylene ether (a=8 , b=2) 467.2g, yield 98.5%.

[0055]ii. Add 237.2 g (0.3 mol) of chlorinated nonylphenol polyoxypropylene polyoxyethylene ether (a=8, b=2) synthesized in i into a four-necked flask equipped with a reflux condensing device, a thermometer and a stirrer , and add 61.4g (0.45 moles) of 33wt% dimethylamine aqueous solution, 30g of water an...

Embodiment 2

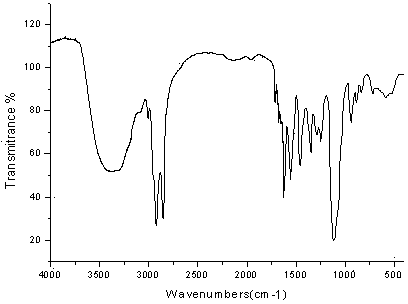

[0061] 1) Synthesis of dodecylphenol polyoxypropylene polyoxyethylene ether betaine [a=6,b=2,R 2= CH 2 CH 2 OH,R 3 =CH 2 CH 2 OH,R 4 =CH 2 CH 2 ,X - = SO 3 - ]

[0062] i. Add 418.8 grams (0.6 moles) of dodecylphenol polyoxypropylene polyoxyethylene ether (a=6, b=2) into a dry four-necked reaction flask equipped with stirring, condensation and tail gas absorption devices, chlorinated 121.4 grams (1.02 moles) of sulfoxide, heated to reflux, kept reflux reaction for 7 hours, after the reaction was finished, treated with [Example 1] to obtain chlorinated dodecylphenol polyoxypropylene polyoxyethylene ether (a=6 , b=2) 418.7g, yield 97.4%.

[0063] ii. Add 215.0 g (0.3 mol) of chlorinated dodecylphenol polyoxypropylene polyoxyethylene ether (a=6, b=2) synthesized in i into a four-port port equipped with a reflux condensing device, a thermometer and a stirrer Add 34.7g (0.33 moles) of diethanolamine, 20g of water and 60g of ethanol to the flask, mix them, heat to 75°C...

Embodiment 3

[0068] 1) Synthesis of tetradecyl polyoxypropylene polyoxyethylene ether betaine [a=4, b=8, R 2= CH 3 , R 3 = CH 3 , R 4 =CH 2 CH 2 ,X - = SO 3 - ]

[0069] i. Add tetradecyl polyoxypropylene polyoxyethylene ether (a=4, b=8) 478.8 g (0.6 moles), chlorinated chlorinated ethylene oxide into a dry four-necked reaction flask equipped with stirring, condensation and tail gas absorption devices. 85.7 grams of sulfone (0.72 mole), heated to reflux, kept reflux reaction for 8 hours, after the reaction was finished, it was treated with [Example 1] to obtain chlorinated tetradecyl polyoxypropylene polyoxyethylene ether (a=4, b =8) 478.6g, yield 97.7%.

[0070] ii. Add 245.0 g (0.3 mol) of chlorinated tetradecyl polyoxypropylene polyoxyethylene ether (a=4, b=8) synthesized in i into a four-necked flask equipped with a reflux condensing device, a thermometer and a stirrer Add 73.6g (0.54 moles) of 33wt% dimethylamine aqueous solution, 30g water and 90g n-propanol to mix, heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com