Device and method for preparing wear-resistant and anti-rust coating on inner wall of pipe

An anti-rust coating and tube inner wall technology, applied in heating inorganic powder coating and other directions, can solve problems such as uneven coating, and achieve the effects of simple process, high hardness and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

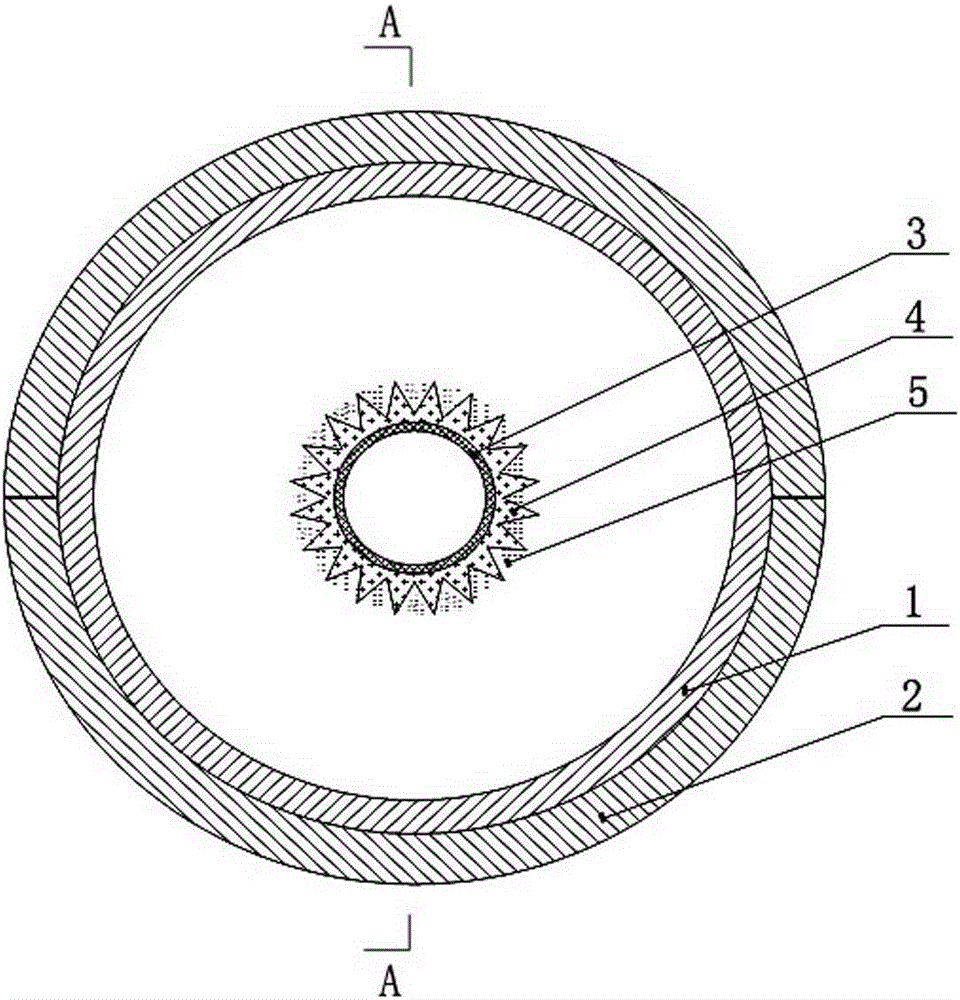

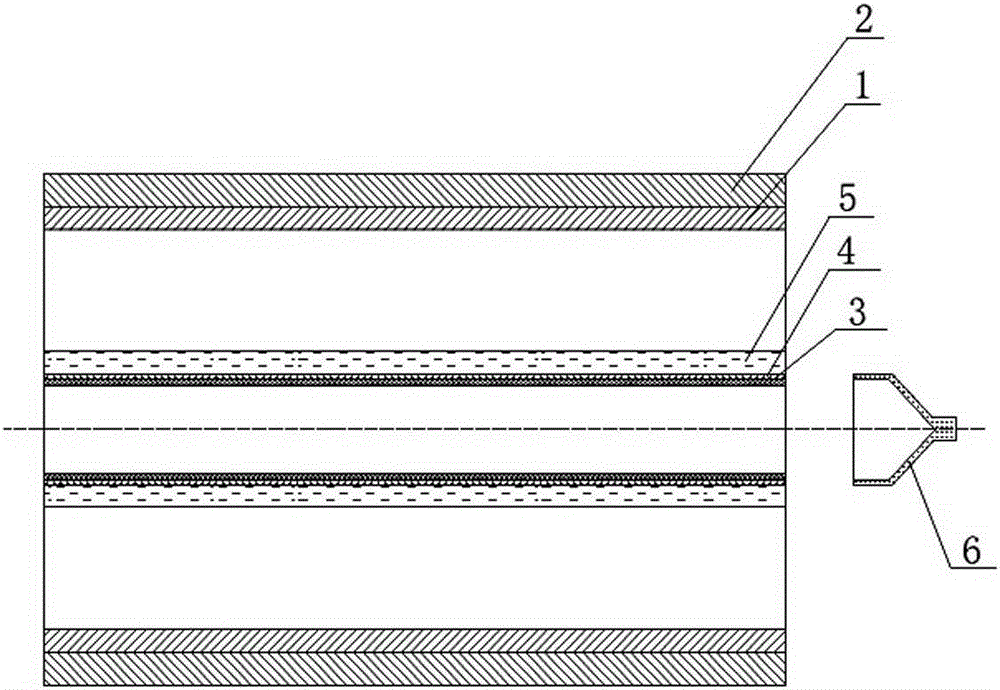

[0022] A device for preparing a wear-resistant and anti-rust coating on the inner wall of a large-diameter pipe, comprising a substrate pipe 1 to be sprayed, an energy absorption pipe 2 is placed outside the substrate pipe 1 to be sprayed, and the wall thickness of the energy absorption pipe 2 is greater than the substrate to be sprayed The wall thickness of the tube 1 is provided with a liner 3 in the base tube 1 to be sprayed, and the axes of the liner 3, the energy absorbing tube 2 and the base tube 1 to be sprayed coincide; The outer wall of the outer pipe is provided with a layer of annular explosive charge layer 4, and the outer wall of the annular explosive charge layer 4 is provided with several adjacent tapered grooves arranged along the axial direction of the inner liner pipe 3. The cone angle of the tapered grooves is 60°, each tapered groove of the annular explosive charge layer 4 is filled with powder to be sprayed 5; the end of the inner liner pipe 3 is equipped w...

Embodiment 2

[0026] A device for preparing a wear-resistant and anti-rust coating on the inner wall of a large-diameter pipe, comprising a substrate pipe 1 to be sprayed, an energy absorption pipe 2 is placed outside the substrate pipe 1 to be sprayed, and the wall thickness of the energy absorption pipe 2 is greater than the substrate to be sprayed The wall thickness of the tube 1 is provided with a liner 3 in the base tube 1 to be sprayed, and the axes of the liner 3, the energy absorbing tube 2 and the base tube 1 to be sprayed coincide; The outer wall of the outer pipe is provided with a layer of annular explosive charge layer 4, and the outer wall of the annular explosive charge layer 4 is provided with several adjacent tapered grooves arranged along the axial direction of the inner liner pipe 3. The cone angle of the tapered grooves is 120°, each tapered groove of the annular explosive charge layer 4 is filled with powder to be sprayed 5; the end of the inner liner pipe 3 is equipped ...

Embodiment 3

[0030] A device for preparing a wear-resistant and anti-rust coating on the inner wall of a large-diameter pipe, comprising a substrate pipe 1 to be sprayed, an energy absorption pipe 2 is placed outside the substrate pipe 1 to be sprayed, and the wall thickness of the energy absorption pipe 2 is greater than the substrate to be sprayed The wall thickness of the tube 1 is provided with a liner 3 in the base tube 1 to be sprayed, and the axes of the liner 3, the energy absorbing tube 2 and the base tube 1 to be sprayed coincide; The outer wall of the outer pipe is provided with a layer of annular explosive charge layer 4, and the outer wall of the annular explosive charge layer 4 is provided with several adjacent tapered grooves arranged along the axial direction of the inner liner pipe 3. The cone angle of the tapered grooves is 90°, each tapered groove of the annular explosive charge layer 4 is filled with powder to be sprayed 5; the end of the inner liner pipe 3 is equipped w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com