Heat preservation demolition-free template and manufacturing method thereof

A technology that avoids dismantling formwork and manufacturing methods, and is applied in the direction of heat preservation, formwork/formwork/work frame, building insulation materials, etc., to achieve rich effects, simple structure, and fire prevention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

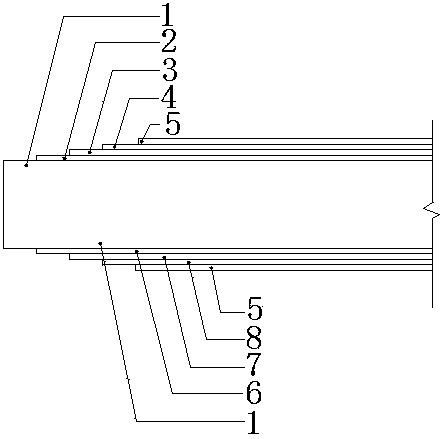

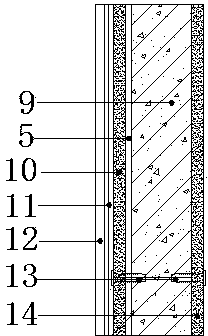

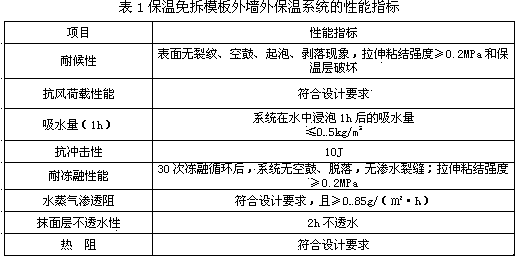

Image

Examples

Embodiment 1

[0055] The method of making the insulation-free formwork is to take the following steps:

[0056] 1. Production of insulation board:

[0057] 1) Put slag wool, expanded perlite, starch, waterproofing agent, flame retardant, flocculant, glass fiber filaments, paper pulp, and water into the mixing tank according to the weight ratio, mix and stir to form a paste, and make it through the slurry method Wet board, in which slag wool, expanded perlite, starch, waterproofing agent, flame retardant, flocculant, glass fiber filaments, pulp, and water weight ratio is:

[0059] Expanded perlite 0.4

[0060] Corn starch 0.1

[0061] Waterproofing agent acrylic emulsion 0.03

[0062] Flame retardant magnesium hydroxide 0.1

[0063] Flocculant aluminum sulfate 0.03

[0064] Glass fiber filament 0.02

[0065] Pulp 0.03

[0066] water 150;

[0067] 2) Transport the wet board into the drying tunnel and dry it at a temperature of 220~270°C for 5~6 hours to make a bl...

Embodiment 2

[0080] The method of making the insulation-free formwork is to take the following steps:

[0081] 1. Production of insulation board:

[0082] 1) Put slag wool, expanded perlite, starch, waterproofing agent, flame retardant, flocculant, glass fiber filaments, paper pulp, and water into the mixing tank according to the weight ratio, mix and stir to form a paste, and make it through the slurry method Wet board, in which slag wool, expanded perlite, starch, waterproofing agent, flame retardant, flocculant, glass fiber filaments, pulp, and water weight ratio is:

[0083] Slag wool 1

[0084] Expanded Perlite 0.5

[0085] Tapioca starch 0.2

[0086] Waterproofing agent pure acrylic emulsion 0.05

[0087] Flame retardant aluminum phosphate 0.1

[0088] Potassium dihydrogen phosphate 0.1

[0089] Flocculant aluminum sulfate 0.05

[0090] Glass fiber filament 0.01

[0091] Pulp 0.05

[0092] water 200;

[0093] 2) Transport the wet board into the drying tunnel and dry it at a...

Embodiment 3

[0107] The method of making the insulation-free formwork is to take the following steps:

[0108] 1. Production of insulation board:

[0109] 1) Put slag wool, expanded perlite, starch, waterproofing agent, flame retardant, flocculant, glass fiber filaments, paper pulp, and water into the mixing tank according to the weight ratio, mix and stir to form a paste, and make it through the slurry method Wet board, in which slag wool, expanded perlite, starch, waterproofing agent, flame retardant, flocculant, glass fiber filaments, pulp, and water weight ratio is:

[0110] Slag wool 1

[0111] Expanded Perlite 0.45

[0112] Corn starch 0.15

[0113] Waterproofing agent EVA emulsion 0.04

[0114] Flame retardant aluminum hydroxide 0.15

[0115] Flocculant aluminum sulfate 0.04

[0116] Glass fiber filament 0.015

[0117] Pulp 0.04

[0118] water 175;

[0119]2) Transport the wet board into the drying tunnel and dry it at a temperature of 220~270°C for 5~6 hours to make a blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com