Pipeline strain real-time detector suitable for high-temperature environment

A real-time detector and pipeline strain technology, applied in instruments, measuring devices, optical devices, etc., can solve the problems of low precision, large workload, long test period, etc., and achieve fast dynamic response, low cost, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

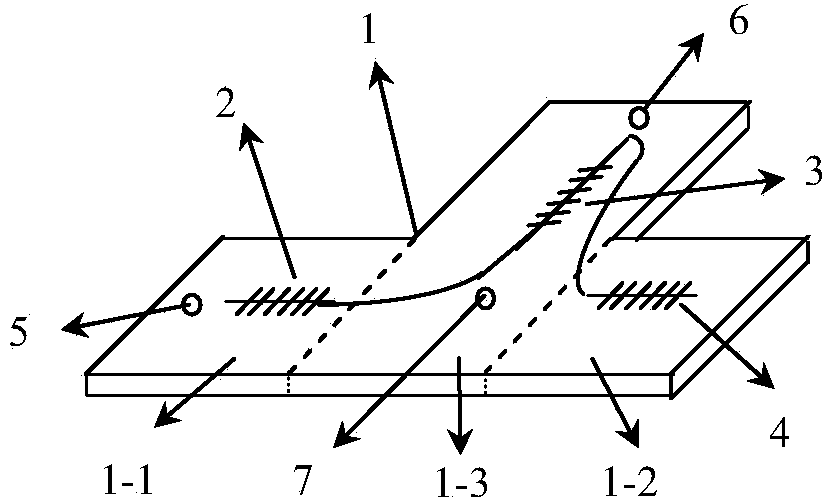

[0047] figure 1 It is a kind of fiber grating type pipe strain real-time detector suitable for high temperature environment used in embodiment 1, embodiment 2 and embodiment 3 of the present invention, which includes sensitive diaphragm 1, axial strain sensitive diaphragm 1- 1. Temperature-sensitive diaphragm 1-2, transverse strain-sensitive diaphragm 1-3, high-temperature optical fiber grating axial strain sensor 2, high-temperature optical fiber grating lateral strain sensor 3, high-temperature optical fiber grating temperature sensor 4, the first welding point 5, the second Second welding point 6, third welding point 7. The sensitive diaphragm 1 is fixed on the high-temperature pipeline to be tested through the first welding point 5, the second welding point 6, and the third welding point 7, and the line formed by the first welding point 5 and the third welding point 7 is in line with the axis of the high-temperature pipeline parallel. Wherein the two ends of the high tem...

Embodiment 2

[0062] The difference from Example 1 is that the high temperature fiber grating axial strain sensor 2, the high temperature fiber grating transverse strain sensor 3 and the high temperature fiber grating temperature sensor 4 are high temperature long period fiber grating sensors with the same material, structure and size, but The three characteristic center wavelengths are different.

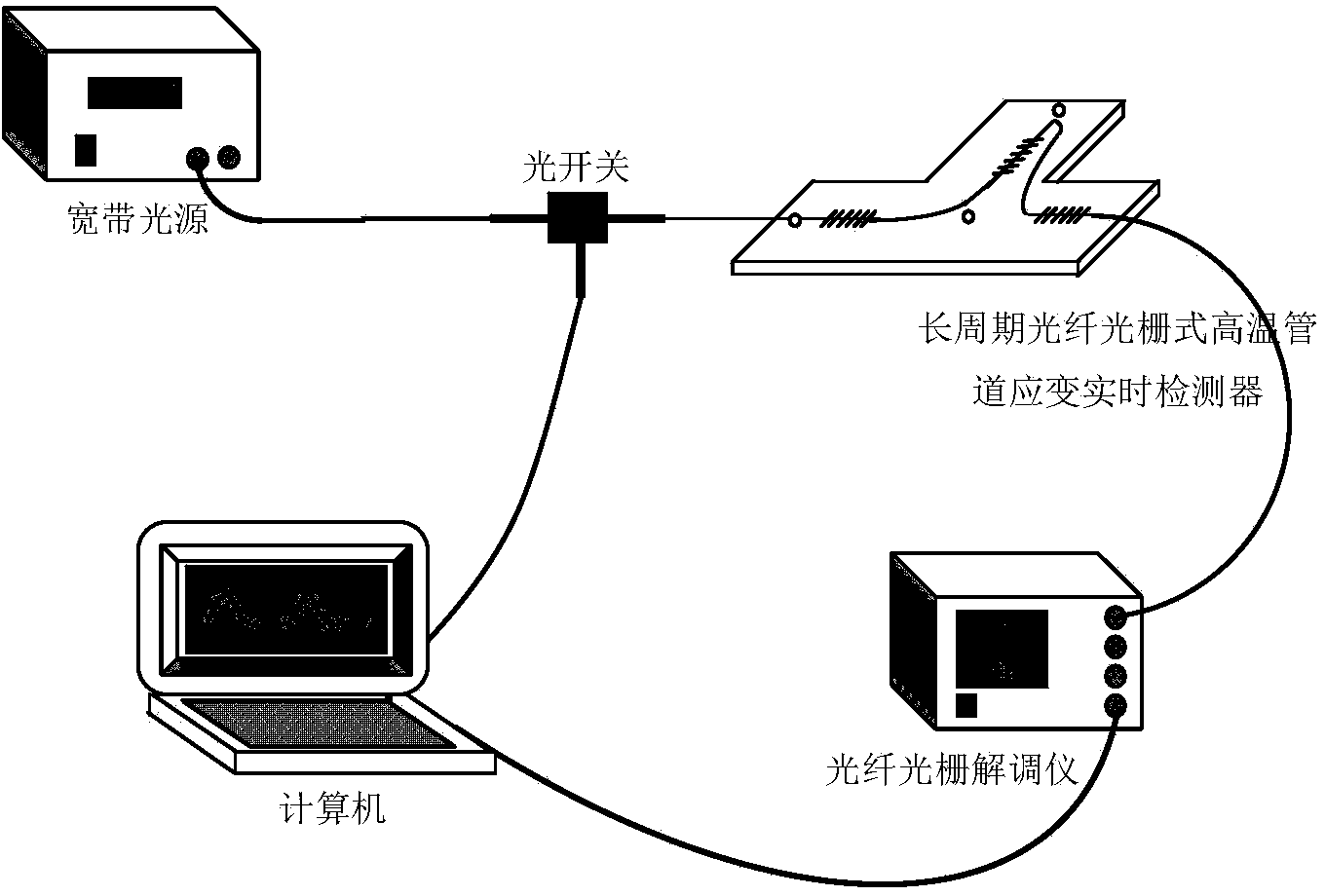

[0063] The three are all made of Polyimide high temperature resistant fiber grating, the length is 8cm, the grating diameter is 125um, the bandwidth is about 4nm, the wave trough spectral width is 35nm, and the maximum attenuation is 18dB, but the characteristic central wavelength of the three is different, respectively lambda 2 =1533nm,λ 3 =1560nm,λ 4 = 1590nm. The long-period fiber grating sensor is a transmission wavelength coding sensor device, which has a corresponding characteristic wavelength shift for temperature and strain. Using a fiber grating demodulator to detect the transmitted ...

Embodiment 3

[0075] Such as Figure 4 As shown, the difference from Example 1 is that on the basis of Example 1, n (n≥2) sensitive diaphragms are arranged in parallel on the high-temperature pipeline, the purpose of which is to distribute the high-temperature pipeline in multiple points type network detection.

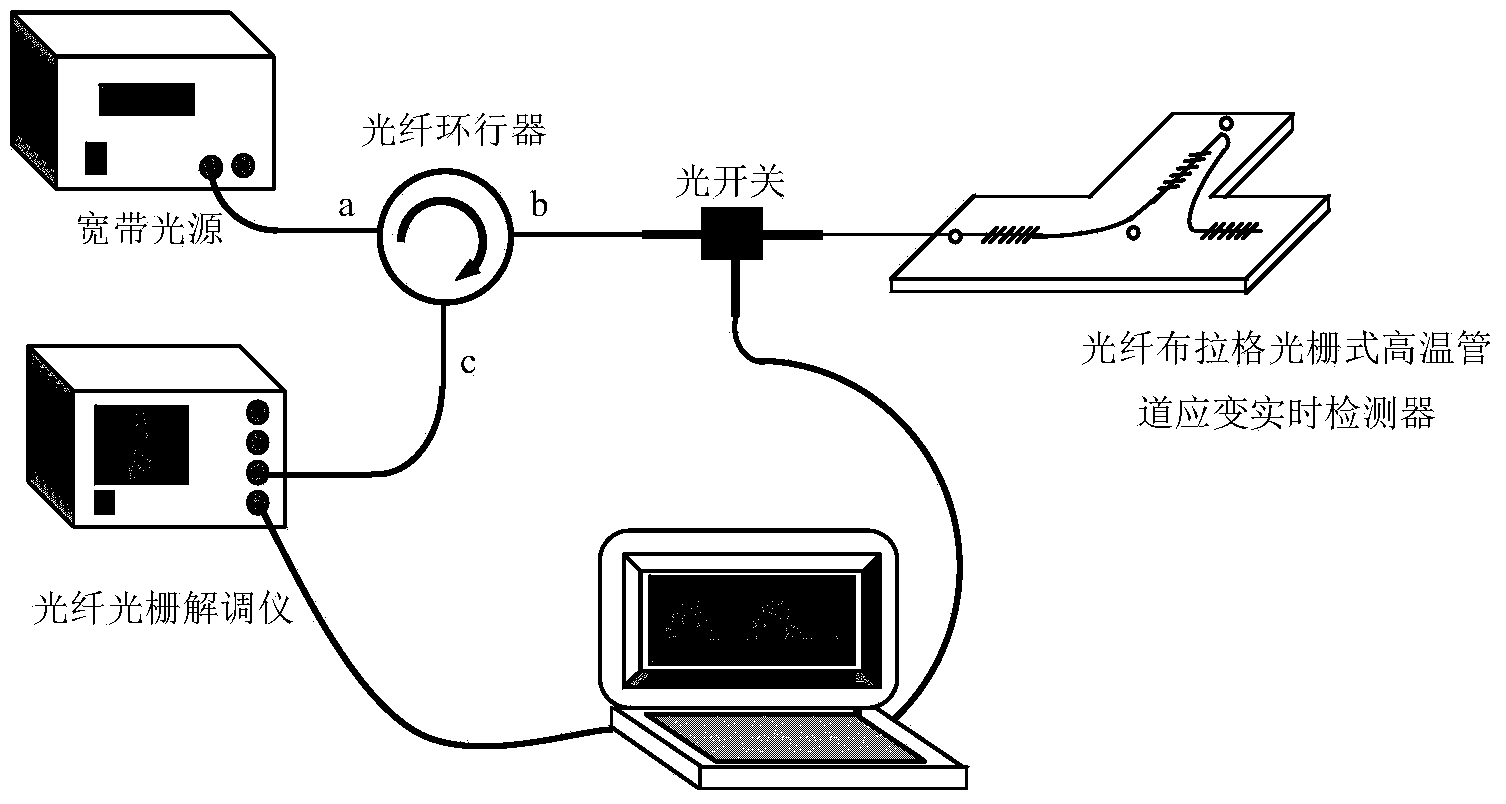

[0076] When the outgoing light wave of the broadband light source passes through the optical fiber circulator, under the control of the optical switch, it enters the serially connected end of the n groups of fiber Bragg grating type pipeline strain real-time detectors.

[0077] Apply strain Δε to the n fiber Bragg grating real-time pipeline strain detectors mentioned above, and the light reflected by the fiber Bragg grating enters the fiber grating demodulator through the fiber circulator, and the computer connected to the demodulator is used to monitor each group of sensors. Center wavelength shift of high temperature fiber Bragg grating.

[0078] For each high-temperature pipel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal length | aaaaa | aaaaa |

| Longitudinal length | aaaaa | aaaaa |

| Horizontal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com