Resin binding product high temperature high temperature granulator and high temperature granulation method

A granulator and high-temperature technology, which is applied in the direction of granulation in the rotary tank, can solve the problems of effective particle reduction, heat loss, and cost increase, and achieve the effects of reducing the impact of viscosity changes, saving operating costs, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

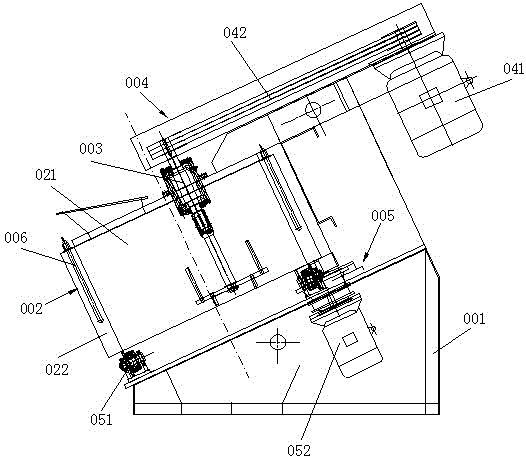

[0032] Example 1: A high-temperature granulator for resin-bonded products, including a frame 001, an inclined rotating cylinder 002 arranged on the frame 001, a transmission device 004 for controlling the high-speed rotation of the agitating rotor 003 in the cylinder 002, and a control cylinder The rotating transmission device 005, the rotating cylinder 002 is an inner and outer double-layer cylinder (021, 022), the outer cylinder 021 is provided with a heating device 006 and filled with a heatable liquid, and the inclined rotating cylinder 002 The angle of inclination is 5~35° with the vertical direction, and the rotation speed of the cylinder is 5~30rpm. The transmission device 004 that controls the high-speed rotation of the stirring rotor 003 in the rotating cylinder 002 includes a stirring motor 041 and a belt transmission system 042 connected to the stirring motor 041 , and the belt transmission system 042 is connected to the stirring rotor 003 in transmission. The trans...

Embodiment 2

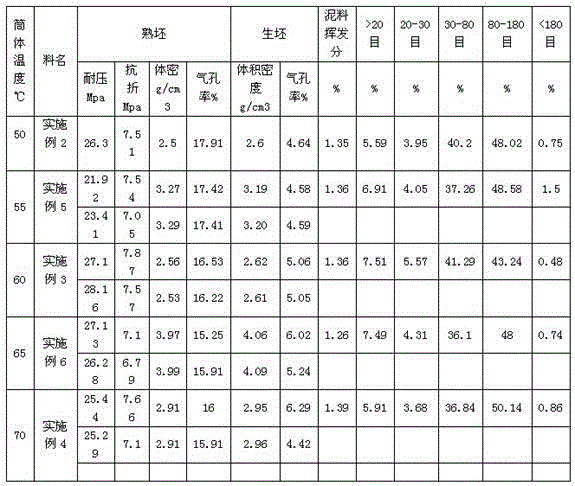

[0033] Embodiment 2: A high-temperature granulation method of a high-temperature granulator for resin-bonded products, comprising the following steps: heating the rotating cylinder to 50°C, adding the granulation raw materials into the rotating cylinder for mixing and stirring, and the rotating speed of the cylinder is 5-30rpm, The stirring speed of the high-speed rotor is 1000~2000rpm, and the stirring time is 10~60 minutes. Finally, the material is discharged and cooled to room temperature to obtain the finished mud. The granulation raw material consists of 23% graphite, aggregate: 47% fused alumina particles, powder with particle size less than 0.074mm: 15% fused alumina micropowder, binder: 10% powdered resin, solvent: furfuryl alcohol and furfural The composition of the combination is 5%, and 4% of silicon carbide powder and 3% of metal silicon powder can be added.

Embodiment 3

[0034] Example 3: Referring to Example 2, the rotating cylinder is heated to 60°C, the granulation raw material is graphite 25%, aggregate: 45% fused alumina particles, powder with a particle size of less than 0.074 mm: fused alumina Micropowder 12%, binder: powdery resin 12%, solvent: furfuryl alcohol and furfural combination 6%, in addition, 4% silicon carbide powder and 3% metal silicon powder can be added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com