Method and system for distillation recycling of dimethyl formamide rectified residual liquid

A technology of dimethylformamide and distillation recovery, which is applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., and can solve the problems of dry burning cracking on the surface of the heating body, cracking of dimethylformamide, and no actual investment from enterprises. Achieve the effects of increasing production capacity, uniform heating, and reducing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The rectification raffinate of dimethylformamide treated in Example 1 is produced in the production of polyurethane synthetic leather by wet process, wherein the content of dimethylformamide is about 22wt%, the water content is about 47wt%, and also contains a certain amount of Solid phase substances such as dander, resin, filler, etc.

[0054] Example 1

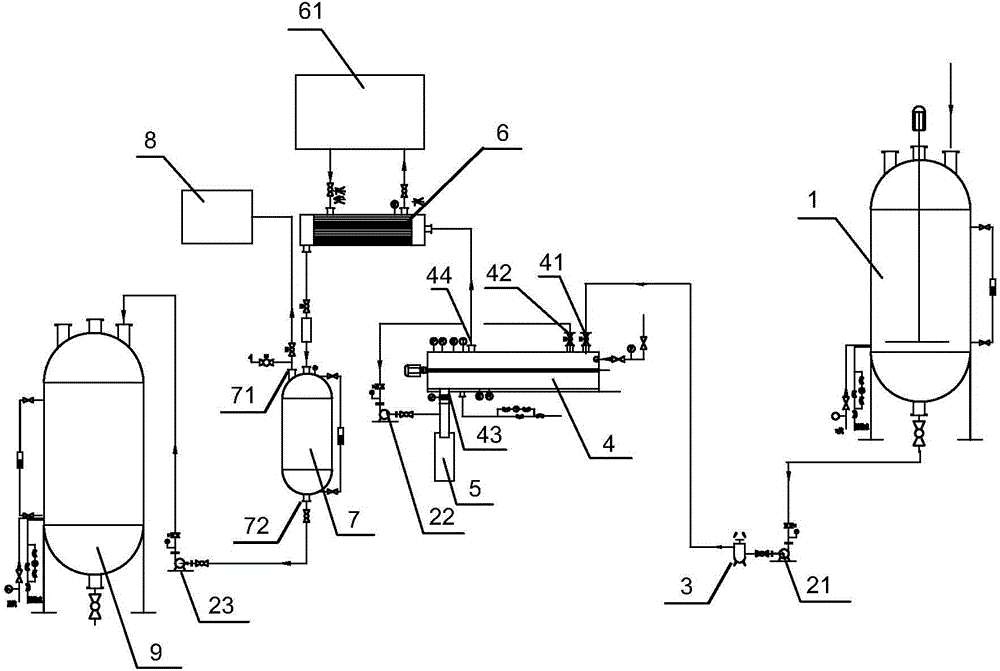

[0055] figure 1 It is a schematic diagram of recovering the rectification raffinate of dimethylformamide by distillation. like figure 1 As shown, the dimethyl formamide rectification raffinate enters the storage tank 1 with a heating jacket and agitator, and is stirred and heated to about 70°C in the storage tank to make it have good fluidity. The pump 21 is pumped into the filter 3 to filter out the solid phase matter, and enter the dryer 4 through the first feed port 41 of the dryer 4 under the action of gravity for distillation. The drier 4 is provided with a heating jacket and a stirrer (not shown), and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com