Environment-friendly formaldehyde-free urea resin and preparation method thereof

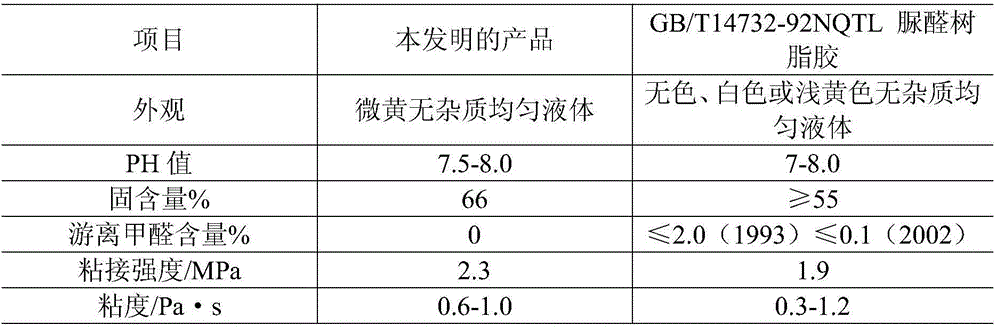

A technology of urea-formaldehyde resin and formaldehyde, which is applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve problems such as impossible eradication, adverse effects on human health and environmental protection, and achieve bonding The effect of high strength, moderate pH and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Environmentally friendly formaldehyde-free urea-formaldehyde resin, which is prepared from urea, dialdehyde starch, formic acid, sodium hydroxide solution, water, borax and tributyl phosphate. The ratio of each raw material is: urea 300kg, dialdehyde starch 135kg, formic acid 0.5 -1kg, sodium hydroxide solution 25-30kg, water 405kg, borax 1.2kg, tributyl phosphate 0.5-1kg.

[0013] The nitrogen content in the urea is greater than 46.4% (mass).

[0014] The mass concentration of described sodium hydroxide solution is 30% (mass).

[0015] The preparation method of above-mentioned environmental protection formaldehyde-free urea-formaldehyde resin, it comprises the steps:

[0016] 1) Selection of raw materials: According to the ratio of each raw material: urea 300kg, dialdehyde starch 135kg, formic acid 0.5-1kg, sodium hydroxide solution 25-30kg, water 405kg, borax 1.2kg, tributyl phosphate 0.5-1kg, select Urea, dialdehyde starch, formic acid, sodium hydroxide solution, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com