3D printing aromatic polyester material and preparation method thereof

A technology of aromatic polyester and polycarbonate, which is applied in the field of 3D printing aromatic polyester materials and its preparation, can solve the problems of unsatisfactory notched impact strength, low friction coefficient, melt fluidity, etc., and achieve easy industrialization The effect of production, material performance improvement, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

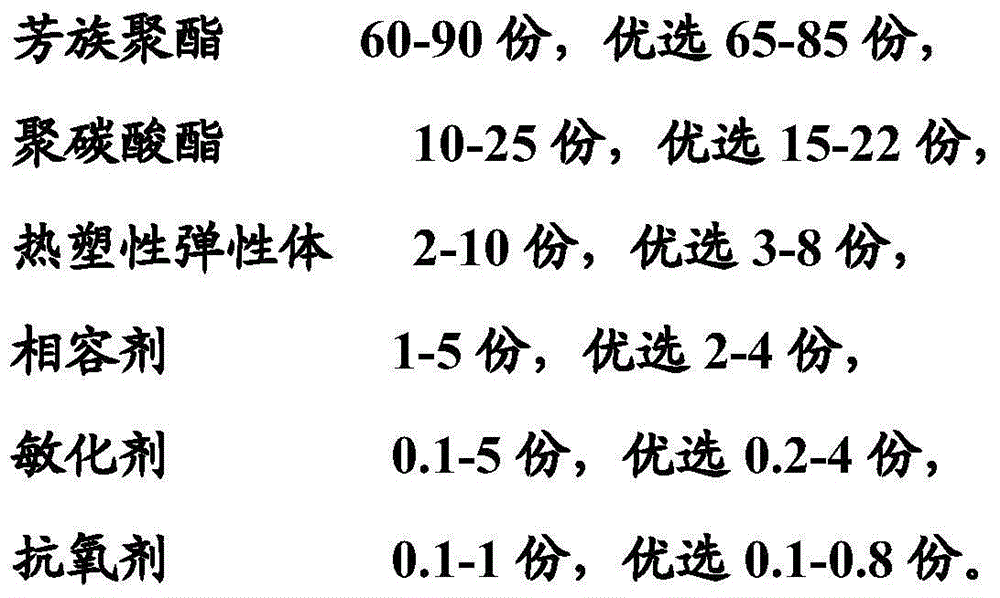

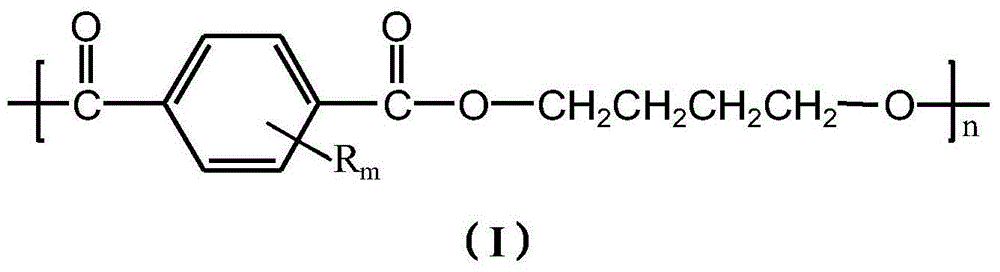

Method used

Image

Examples

Embodiment 1

[0049] First, PBT (intrinsic viscosity: 0.83dL / g) and PC (Makrolon2405) were put into a vacuum oven at 80°C for 10 hours and then cooled to room temperature, and the thermoplastic elastomer was vacuum-dried at room temperature for 12 hours. With 6400g of dried PBT, 2200g of dried PC, 800g of TPEE (Hytrel4778), 300g of polystyrene grafted maleic anhydride (TRD-150B), 20g of HDDA, 20g of TPGDA, 20g of antioxidant 168 and 5g of antioxidant 1010 was mixed evenly with a high-speed mixer, then stretched into thin strips with an average diameter of 1 mm after melt blending with a twin-screw extruder at 250°C, and dried in a vacuum oven at 80°C for 10 hours, and the obtained thin strips were heated in nitrogen Under the conditions of protection and room temperature, electron beam irradiation with a dose of 6mrad is used for cross-linking, and the gel content of the sample is determined to be 9.1% after extraction with tetrachloroethane.

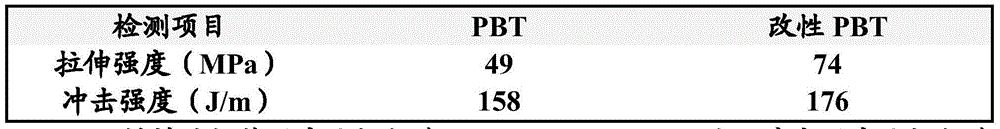

[0050] The main properties of pure PBT and mod...

Embodiment 2

[0054] First, put PBT (intrinsic viscosity 1.03dL / g) and PC (Makrolon2605) into a vacuum oven at 85°C for 10 hours and then cool to room temperature, and then vacuum-dry the thermoplastic elastomer at room temperature for 12 hours. With 7800g of dried PBT, 1500g of dried PC, 200g of TPEE (Hytrel7246), 200g of TPU (Apilon526013), 400g of polystyrene grafted maleic anhydride (TRD-150B), 300g of BDDA, 20g of TPGDA, 10g of antioxidant 168 and 50g of antioxidant 1035 were mixed uniformly with a high-speed mixer, then stretched into thin strips with an average diameter of 1 mm after melt blending at 255°C with a twin-screw extruder, and dried in a vacuum oven at 80°C for 10 After 1 hour, the thin strips obtained were cross-linked by electron beam irradiation at a dose of 24 mrad under nitrogen protection and room temperature conditions, and the gel content was determined to be 35.5% after the sample was extracted with tetrachloroethane.

[0055] The main properties of pure PBT and m...

Embodiment 3

[0058] First, put PBT (intrinsic viscosity 1.10dL / g) and PC (Makrolon2605) into a vacuum oven at 85°C for 12 hours and then cool to room temperature, and then vacuum-dry the thermoplastic elastomer at room temperature for 12 hours. With 800g dried PBT, 150g dried PC, 50g POE (Engage8150), 20g SEBS (Dryflex47722), 20g polystyrene grafted maleic anhydride (TRD-150B), 10g ABS grafted maleic anhydride ( TRD-400), 3g of TMPTA, 10g of TPGDA, 2g of antioxidant 1010 and 7g of antioxidant 1076 were mixed uniformly with a high-speed mixer, and then stretched into an average Thin strips with a diameter of 1 mm are dried in a vacuum oven at 80°C for 10 hours, and the obtained thin strips are cross-linked with 20 mrad of electron beam irradiation under nitrogen protection and room temperature conditions, and the gel content is determined after the sample is extracted with tetrachloroethane was 26.4%.

[0059] The main properties of pure PBT and modified PBT were tested, and the test resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com