Stainless steel equipment cleaning agent, cleaning solution and cleaning method

A stainless steel and cleaning agent technology, applied in the chemical industry, can solve the problems of inability to discharge directly, labor and time-consuming, affecting cleaning speed, etc., and achieve the effect of promoting cleaning speed, good decontamination effect, and good descale effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

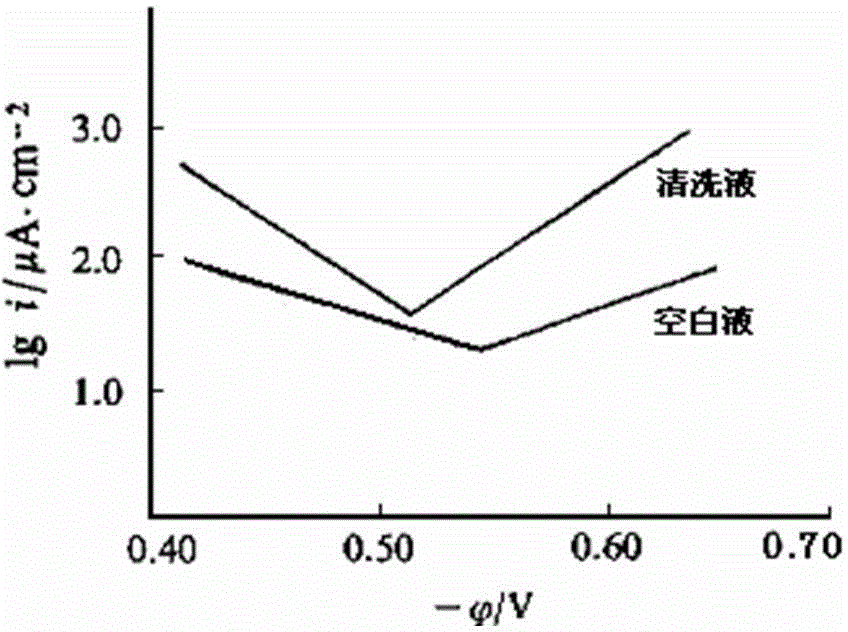

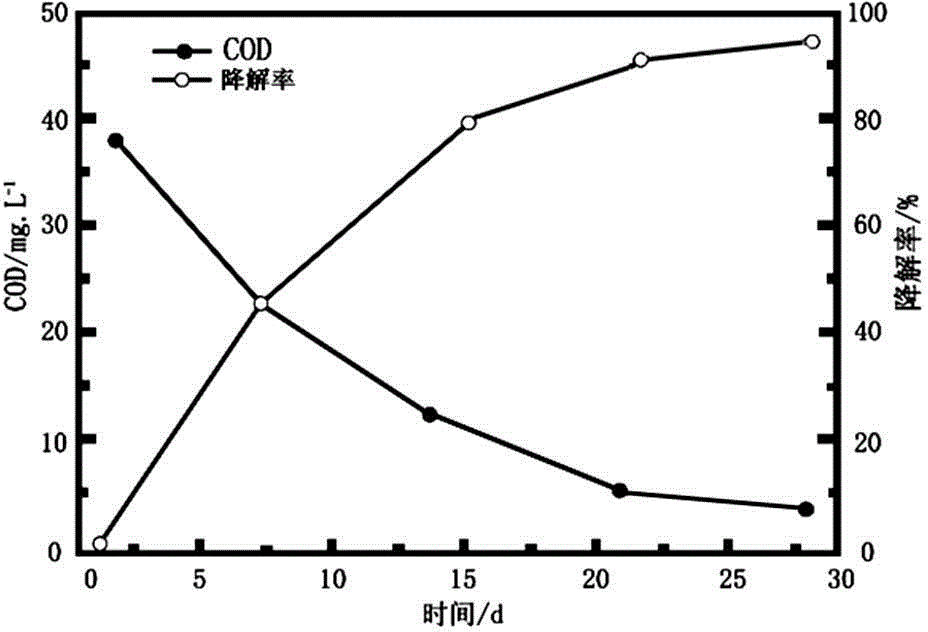

[0039] In order to illustrate the beneficial effect and performance of this cleaning agent, the concrete steps of the present embodiment are as follows:

[0040]1) Prepare polyglycolic acid (molecular weight of polyglycolic acid is 8000), biochemical fulvic acid, aminoacetic acid and water, and prepare according to 100 kg of cleaning solution, and the weight ratio of each component is a: b: c: d=6: 8 : 3: 83;

[0041] 2) Take two-thirds of the water and heat it to the required temperature of the circulating fluid at 50°C, add aminoacetic acid and stir evenly, add biochemical fulvic acid and stir to dissolve, and obtain A solution;

[0042] 3) Take the remaining water and add polyglycolic acid, stir and dissolve to obtain solution B;

[0043] 4) Mix A solution and B solution.

[0044] In this embodiment, the specific physical and chemical indicators of the cleaning agent, the test results of the corrosiveness to stainless steel and the dirt cleaning rate are shown in Table 1-...

Embodiment 2-4

[0106] The weight composition of the cleaning agent in Examples 2-4 and the amount of water required to prepare the corresponding cleaning solution are shown in Table 6.

[0107] Table 6 The composition of the cleaning agent of Example 2-4 and the amount of water required to prepare the corresponding cleaning solution

[0108]

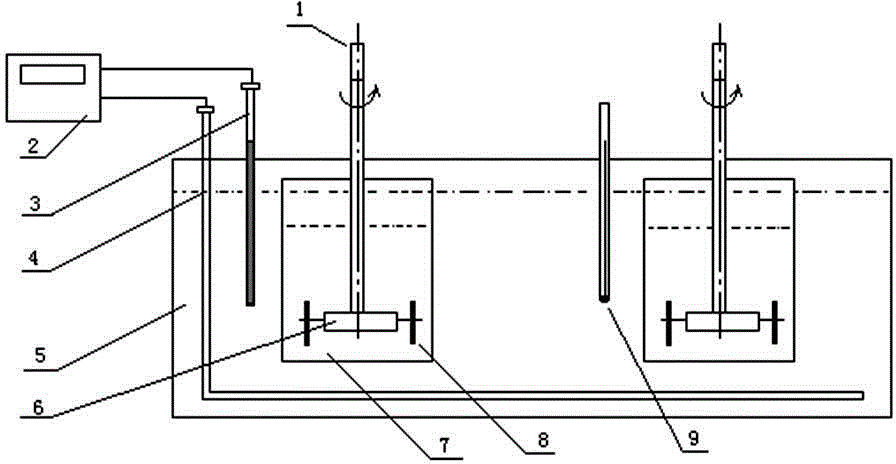

[0109] Stainless steel equipment cleaning method, including the following steps:

[0110] (1) Material preparation: refer to Figure 6 Calculate the capacity of the equipment to be cleaned according to the cycle flow chart; prepare polyglycolic acid, biochemical fulvic acid, glycine and water with reference to the dosage ratio in Table 6;

[0111] (2) Take two-thirds of the water and heat it to the required temperature of the circulating fluid, add aminoacetic acid and stir evenly, add biochemical fulvic acid and stir to dissolve, and obtain A solution;

[0112] (3) Take the remaining one-third of the water and add polyglycolic acid, stir to disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| descaling rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com