A kind of preparation method of nano-gold immune chromatography capillary

A technology of immunochromatography and capillary, which is applied in the field of immunoassay, can solve the problems of complex substrate structure of paper materials, complex assembly and detection process, difficult control of fixed amount and boundary, etc., and achieves simple and easy to master assembly technology, low cost, The effect of reducing inter-assay and intra-assay variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

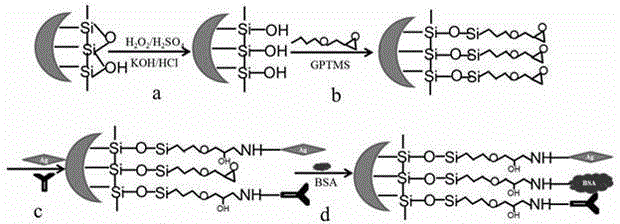

[0059] (1) Handling of capillary :

[0060] Preparation of piranha solution: Mix 95wt% concentrated sulfuric acid and 30wt% hydrogen peroxide at a volume ratio of 4:1. When mixing, slowly add the hydrogen peroxide solution into the concentrated sulfuric acid, and keep stirring to keep the temperature of the mixture below 80°C.

[0061] Quickly immerse the capillary in the above-mentioned hot piranha solution for ultrasonic cleaning for 15 minutes, wash with ultrapure water until neutral, dry in an oven at 105°C for 2 hours, cool down, and then immerse the capillary in sequence with a concentration of 0.8mol / L KOH solution (200mL), Ultrapure water (200mL, replaced twice in the middle), HCl solution (200mL) with a concentration of 0.8mol / L, ultrapure water (200mL, replaced twice in the middle) and acetone (200mL) were ultrasonically cleaned for 15min, and then cleaned at 105 Dry in an oven at ℃ for more than 1 hour to completely remove the moisture.

[0062] (2) Modification...

Embodiment 2

[0068] (1) Handling of capillary :

[0069] Preparation of piranha solution: Mix 98wt% concentrated sulfuric acid and 30wt% hydrogen peroxide at a volume ratio of 3:1. When mixing, slowly add the hydrogen peroxide solution into the concentrated sulfuric acid, and keep stirring to keep the temperature of the mixture below 80°C.

[0070] Quickly immerse the capillary in the above-mentioned hot piranha solution for ultrasonic cleaning for 20 minutes, wash it with ultrapure water until neutral, dry it in an oven at 105°C for 1 hour, and cool it down. Ultrapure water (200mL, replaced twice in the middle), HCl solution with a concentration of 1.2mol / L (200mL), ultrapure water (200mL, replaced twice in the middle) and ethanol (200mL) were ultrasonically cleaned for 15min, and then cleaned at 105 Dry in an oven at ℃ for more than 1 hour to completely remove moisture.

[0071] (2) Modification of capillary :

[0072] Preparation of anhydrous toluene: Add 30g of anhydrous sodium su...

Embodiment 3

[0077] (1) Handling of capillary :

[0078] Preparation of piranha solution: Mix 98wt% concentrated sulfuric acid and 30wt% hydrogen peroxide at a volume ratio of 3:1. When mixing, slowly add the hydrogen peroxide solution into the concentrated sulfuric acid, and keep stirring to keep the temperature of the mixture below 80°C.

[0079] Quickly immerse the capillary in the above-mentioned hot piranha solution for ultrasonic cleaning for 18 minutes, wash with ultrapure water until neutral, dry in an oven at 105°C for 3 hours, and cool down. Ultrasonic cleaning in pure water (200mL, replaced twice in the middle), HCl solution with a concentration of 1mol / L (200mL), ultrapure water (200mL, replaced twice in the middle) and acetone (200mL) for 12min respectively, and then at 105℃ Dry in an oven for more than 1 hour to completely remove moisture.

[0080] (2) Modification of capillary :

[0081] Preparation of anhydrous toluene: Add 20g of anhydrous sodium sulfate to 300mL of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com