Method for preparing solid amine CO2 adsorption material based on nano-silica dipping

A nano-silica, adsorption material technology, applied in chemical instruments and methods, through adsorption, separation methods and other directions, can solve problems such as the inability to use carbon dioxide capture, and achieve strong competitiveness, easy desorption, and low energy consumption for desorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

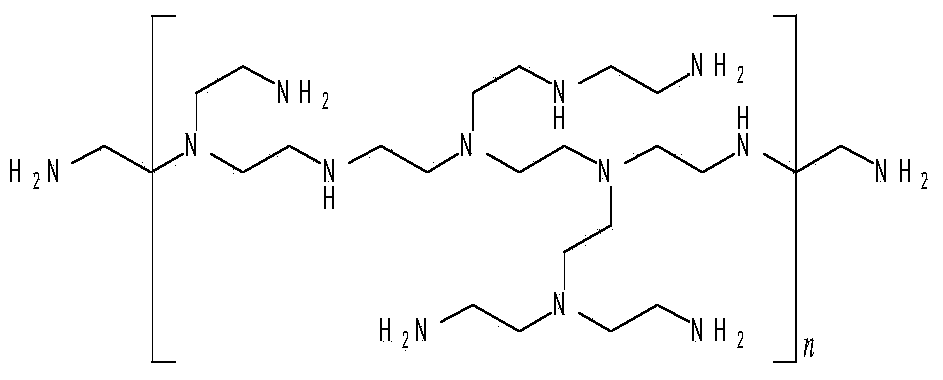

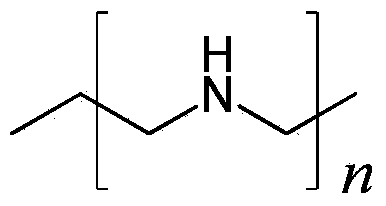

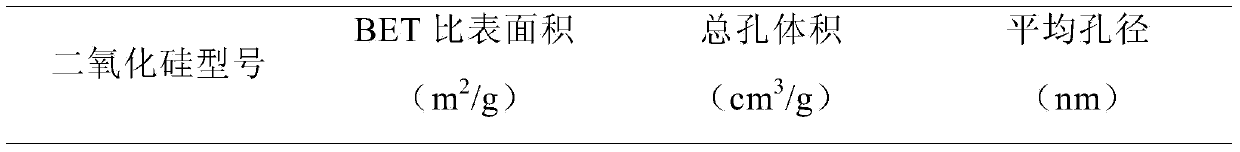

[0022] A preparation of solid-state amine CO based on nano-silica impregnation 2 The method of adsorption material, first weigh 0.86g branched PEI with a molecular weight of 600Da with a 150ml beaker, then add 25ml of methanol to the beaker, stir at room temperature for 30 minutes, and completely dissolve the PEI in methanol. Then weigh 2g of nano-silica (the nano-silica used has been vacuum-dried (≤1mmHg) at 105°C for 3 hours), add it into a beaker, and then add 5ml of methanol. Afterwards, stir at room temperature for 5 hours. After the liquid in the beaker becomes very viscous, dry it in an oven at 50°C for 2 hours, and then place it in a vacuum (≤1mmHg) drying oven. Dry at 50°C for 2 hours. Through elemental analysis, it can be determined that the PEI loading of the prepared material is 30%. Name the sample: 30% BPEI / 600-silica.

Embodiment 2

[0024] A preparation of solid-state amine CO based on nano-silica impregnation 2 The method of adsorption material, at first weighs the branched PEI that the molecular weight of 2.26g is 600Da with the beaker of 150ml, then adds the methanol of 25ml in the beaker, stirs 30 minutes at room temperature, PEI is dissolved in the methanol completely. Then weigh 2g of nano-silica (the nano-silica used has been vacuum-dried (≤1mmHg) at 105°C for 3 hours), add it into a beaker, and then add 5ml of methanol. Afterwards, stir at room temperature for 5 hours. After the liquid in the beaker becomes very viscous, dry it in an oven at 50°C for 2 hours, and then place it in a vacuum (≤1mmHg) drying oven. Dry at 50°C for 2 hours. Through elemental analysis, it can be determined that the PEI loading of the prepared material is 50%. Name the sample: 50% BPEI / 600-silica.

Embodiment 3

[0026] A preparation of solid-state amine CO based on nano-silica impregnation 2 The method of adsorption material, first weigh 3.88g branched PEI with a molecular weight of 600Da with a 150ml beaker, then add 25ml of methanol to the beaker, stir at room temperature for 30 minutes, and completely dissolve the PEI in methanol. Then weigh 2g of nano-silica (the nano-silica used has been vacuum-dried (≤1mmHg) at 105°C for 3 hours), add it into a beaker, and then add 5ml of methanol. Afterwards, stir at room temperature for 5 hours. After the liquid in the beaker becomes very viscous, dry it in an oven at 50°C for 2 hours, and then place it in a vacuum (≤1mmHg) drying oven. Dry at 50°C for 2 hours. Through elemental analysis, it can be determined that the PEI loading of the prepared material is 60%. Name the sample: 60% BPEI / 600-silica.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com