A process for pretreating high-phosphorus wastewater to remove total phosphorus and its process system

A technology for pretreatment and water treatment, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of unsatisfactory treatment effect and high cost, and reduce the treatment burden , treatment cost saving, the effect of eliminating phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific examples, but not as a limitation to the present invention.

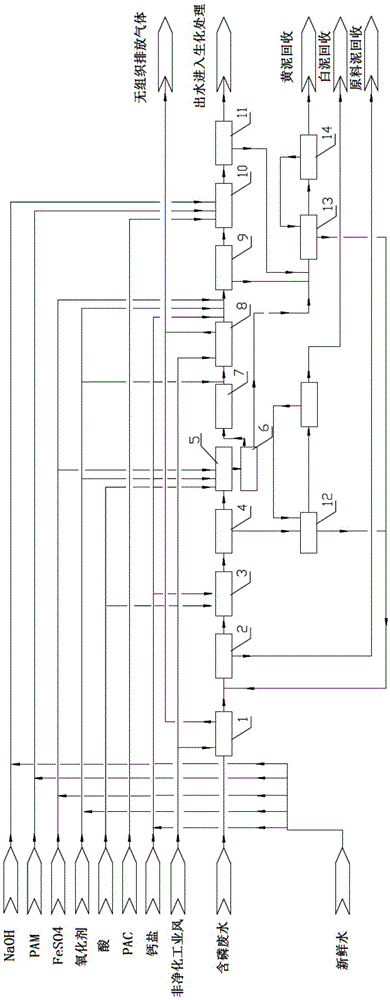

[0044] Such as figure 1 The process for removing total phosphorus from pretreated high-phosphorus wastewater and its process system includes the following steps to complete the removal of total phosphorus from wastewater, so as to obtain wastewater that meets the standard of direct exclusion:

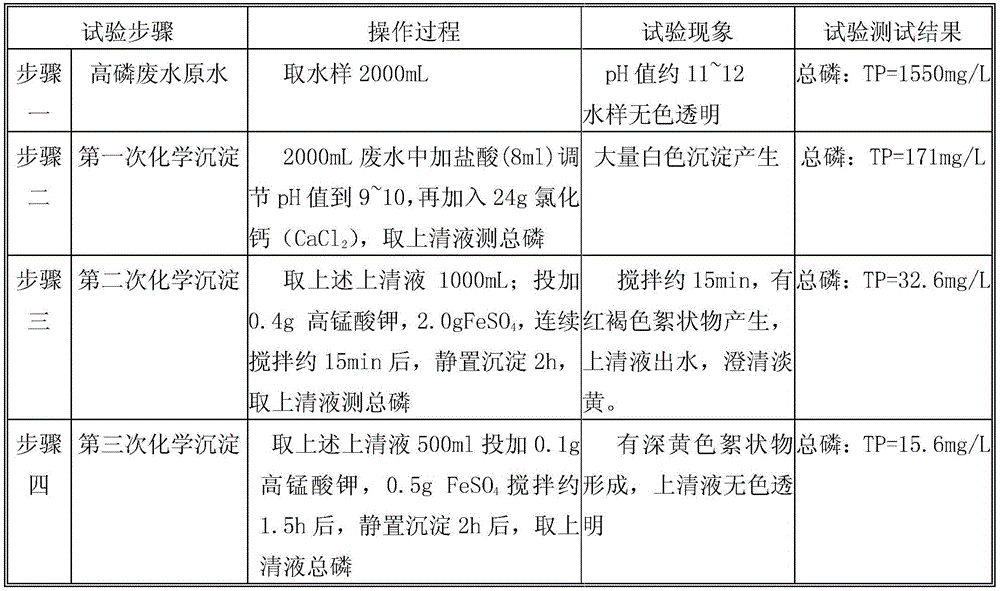

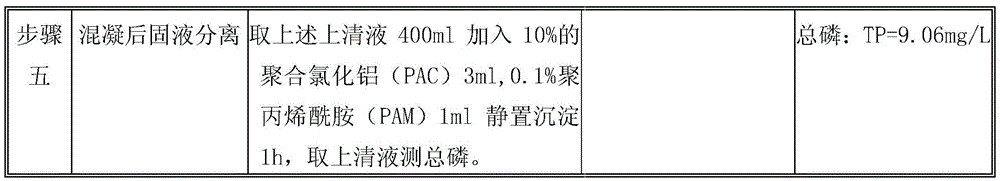

[0045] (1) The first chemical precipitation: High-concentration phosphorus-containing wastewater enters the sewage storage tank 1, is aerated and homogenized by industrial wind, and enters the regulating sedimentation tank 2 after being pre-oxidized; the raw material sludge produced in the regulating sedimentation tank 2 is recycled, and the supernatant The liquid is lifted to the first chemical reaction tank 3 through the primary lifting pump, and an appropriate amount of hydrochloric acid is added through the metering pump to control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com