Sludge dewatering treatment system

A treatment system and sludge dewatering technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of river and lake water levels and the adverse effects of sediment ecology, and achieve easy sludge resource utilization, low operating costs, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

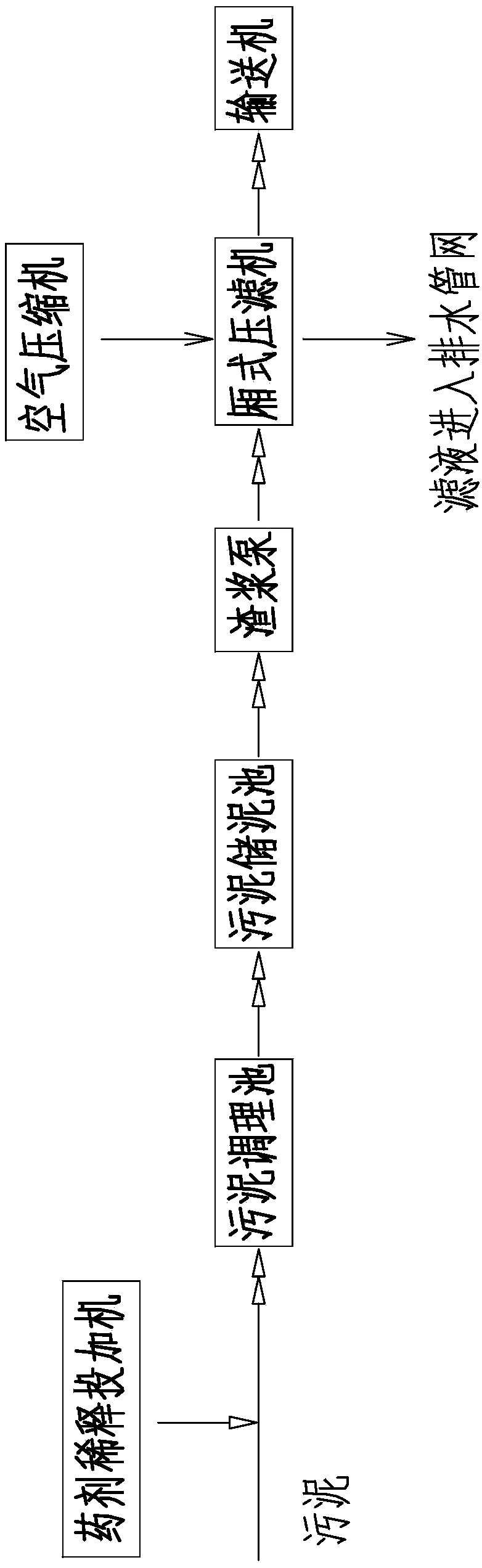

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific examples.

[0010] The sludge dewatering treatment system includes a chemical dilution dosing machine 1, a sludge conditioning tank 2, a sludge storage tank 3, a slurry pump 4, a box filter press 5, a conveyor 6, and an air compressor 7. The discharge end of the dilution dosing machine 1 is connected to the sludge inlet pipe through the pipeline, the discharge end of the sludge inlet pipe is connected to the feed end of the sludge conditioning tank 2, and the discharge end of the sludge conditioning tank 2 passes through the pipeline Connect the feed end of the sludge storage tank 3, the discharge end of the sludge storage tank 3 is connected to the feed end of the slurry pump 4 through a pipeline, and the discharge end of the slurry pump 4 is connected to the chamber filter press through a pipeline 5, the discharge end of the box filter press 5 is connected to the feed end of the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com