ITO powder, ITO painting for conductive film and manufacture method for transparent conductive film

A technology of conductive film and powder, which is applied in the field of ITO powder, can solve the problems of performance deterioration, resistance increase of transparent conductive film, and easy generation of voids in ITO micro-powder, so as to achieve the effect of increasing contact area and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] Hereinafter, examples and comparative examples of the present invention will be described in detail.

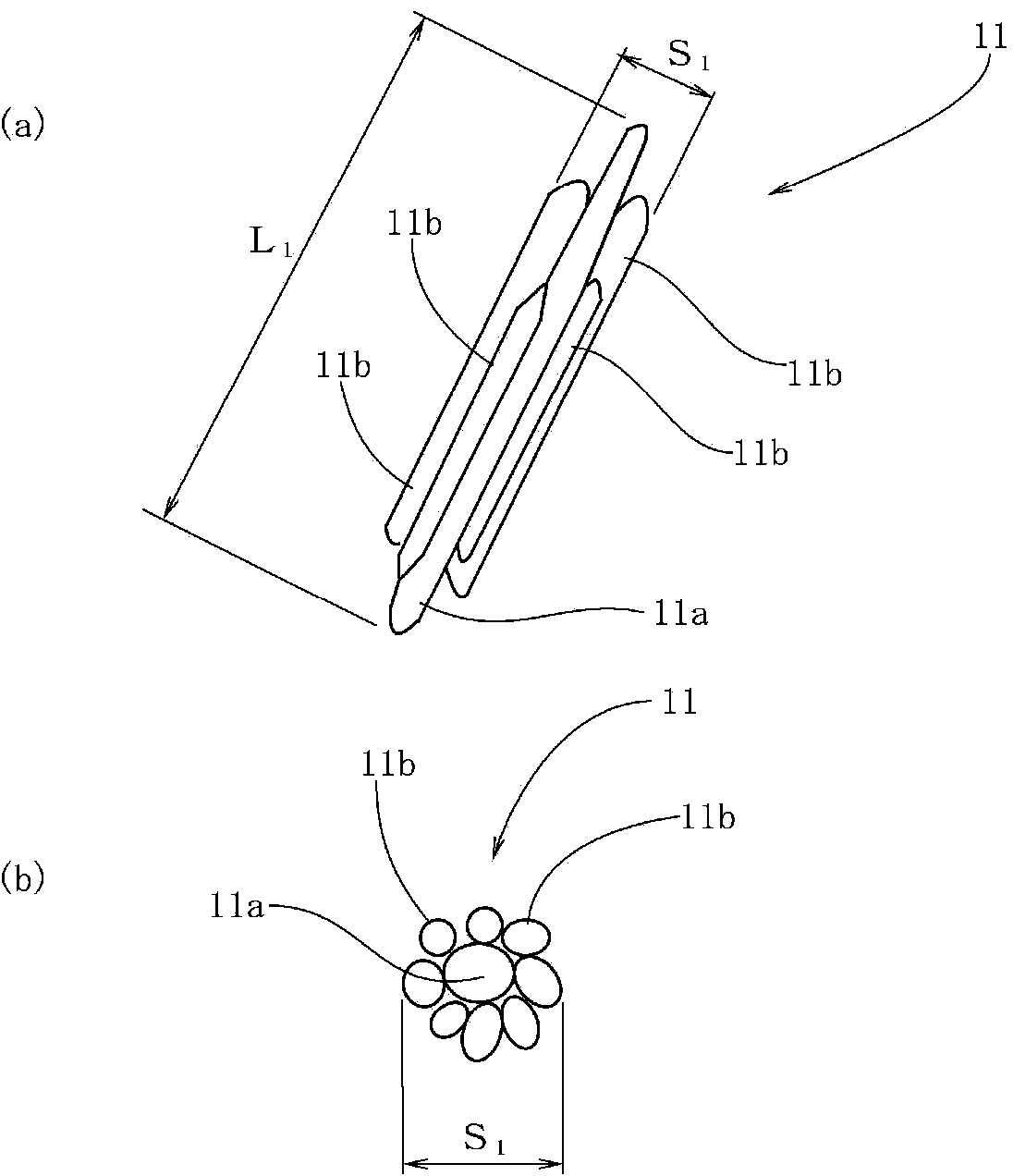

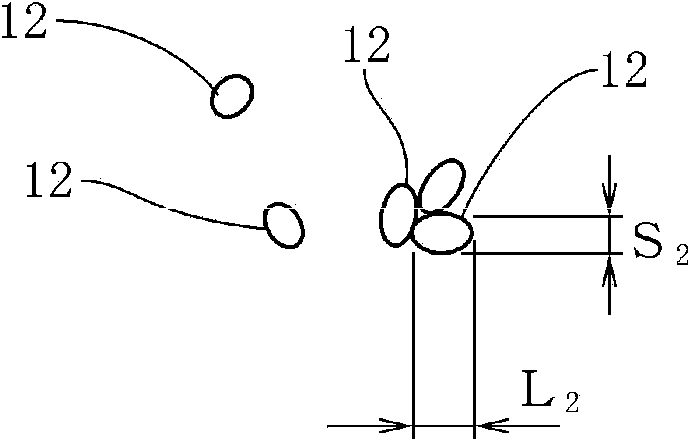

[0053]

[0054] In order to make the first powder, first weigh an indium chloride aqueous solution (InCl 3 ) 100g and tin chloride (SnCl 4 ·5H 2 O) 6.3g was dissolved in 2000ml of pure water to prepare a mixed solution of indium chloride and tin chloride. The concentration of tin in this mixed solution was adjusted so that the molar ratio of Sn / In was 0.10. This mixed solution of indium chloride and tin chloride was heated to 60° C., and 29% by mass of ammonia water was gradually added over 160 minutes to prepare a tin-containing indium hydroxide suspension. Next, aqueous ammonia was added to the suspension, and ultrasonic waves of 34 kHz were applied to the suspension to prevent aggregation and produce aggregates of polycrystalline ITO particles while precipitation was being produced. The suspension containing tin-indium hydroxide was collected by filtration and...

Embodiment 2

[0064] Except for the average major axis diameter L of the first powder 1 Except for 200 nm, it carried out similarly to Example 1, and produced the transparent conductive film. This transparent conductive film was referred to as Example 2.

Embodiment 3

[0066] In addition to changing the ultrasonic irradiation of the suspension so that the average long-axis diameter L of the first powder 1 A transparent conductive film was produced in the same manner as in Example 1 except that the total reaction time was 3000 nm. This transparent conductive film was referred to as Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com