System and method for cracking of methyl tertiary butyl ether to prepare high purity isobutylene

A technology of methyl tert-butyl ether and pure isobutene, which is applied in the field of rectification, can solve the problems of high energy consumption in methanol water distillation, low purity of methanol products, and high consumption of multi-tower separations, so as to achieve energy saving, high yield, The effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

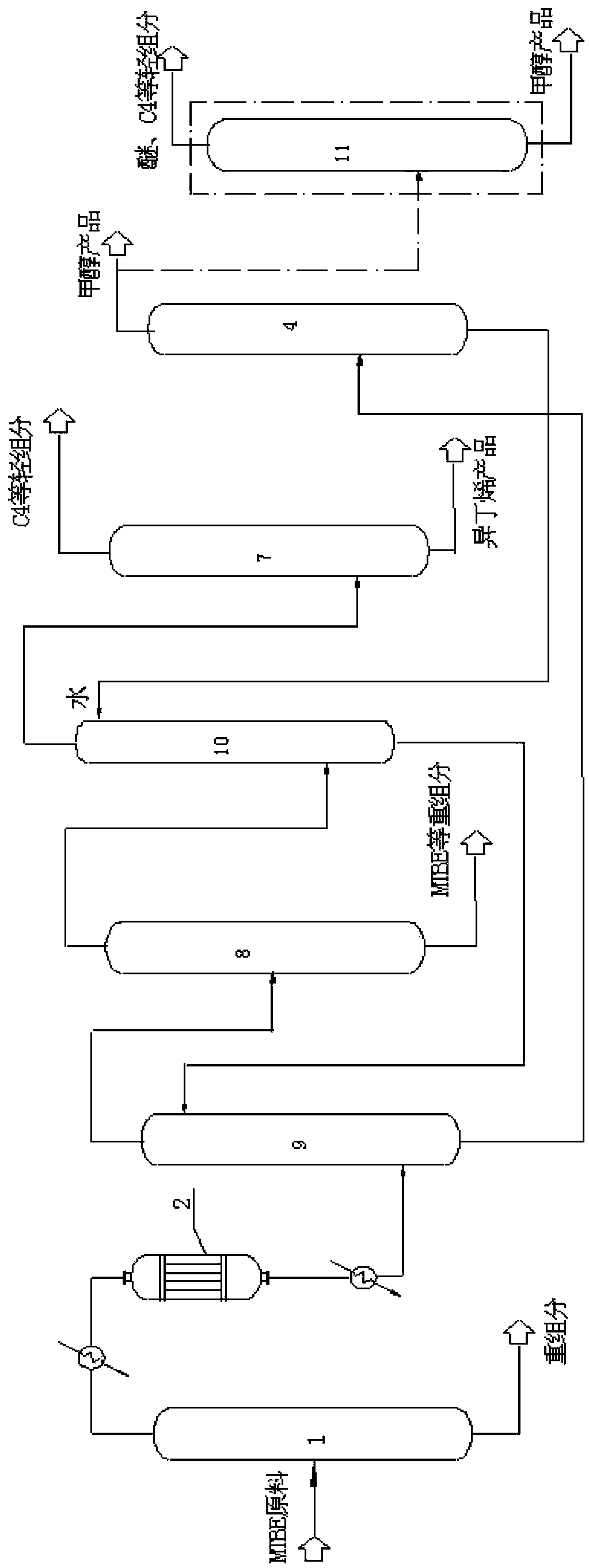

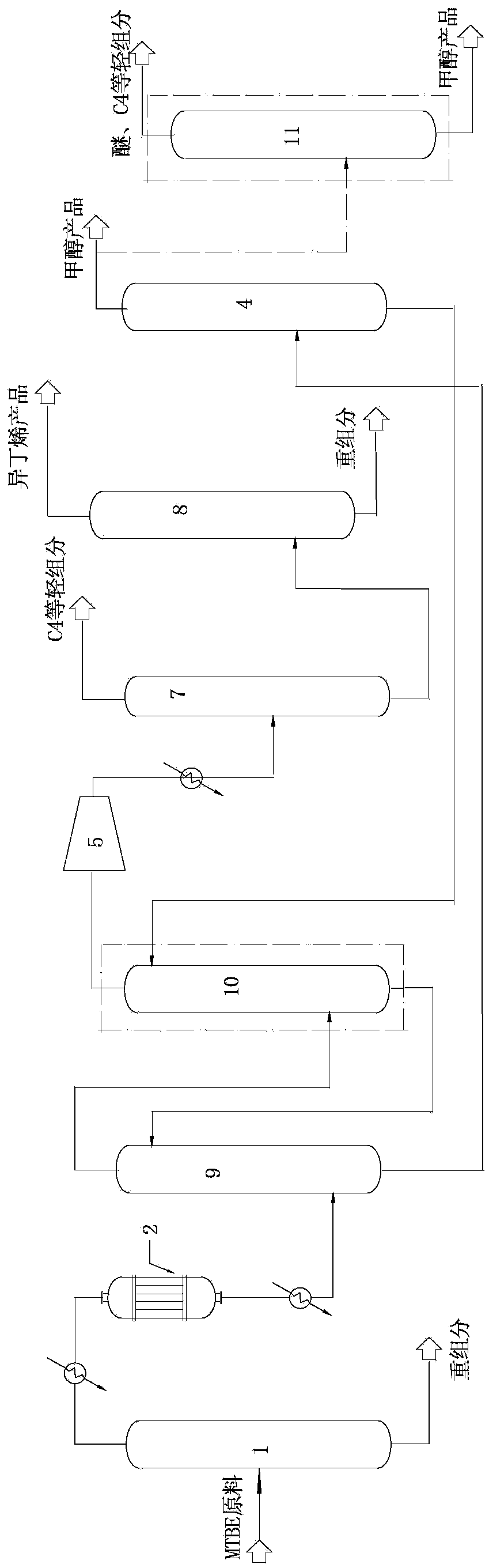

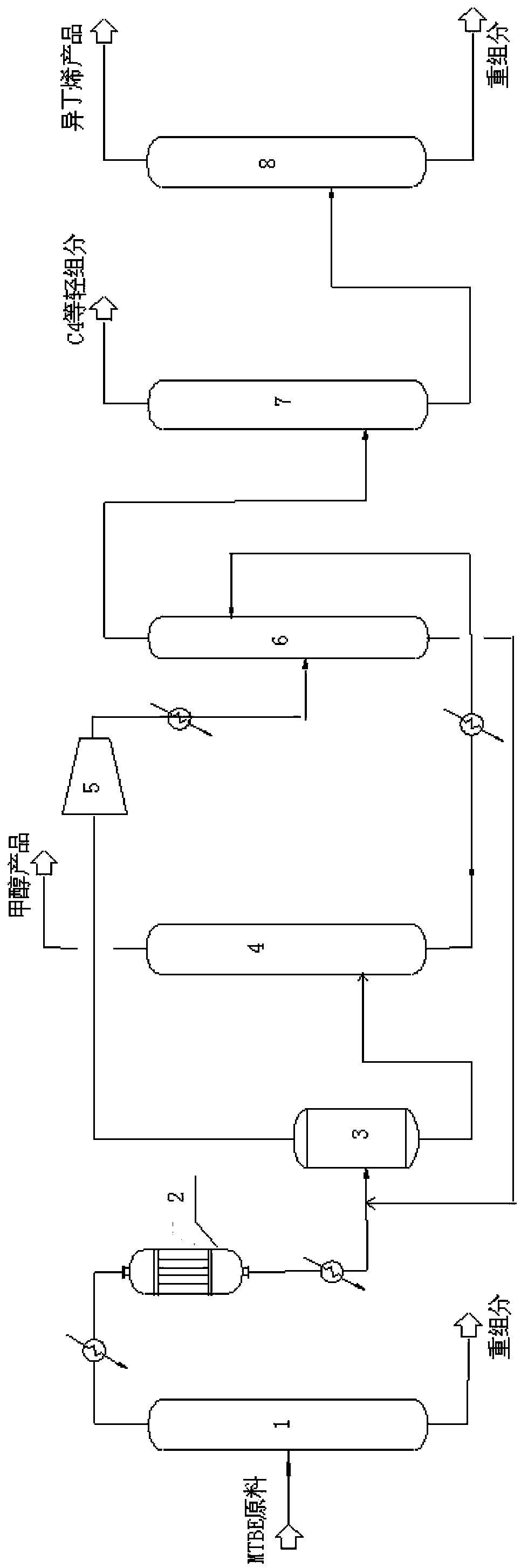

[0072] Process flow

[0073] by Figure 5 The connection and installation of the middle pipeline to obtain the system of methyl tert-butyl ether cracking to produce high-purity isobutylene. The process flow of cracking reaction under normal pressure is as follows: image 3 As shown, the bottom of the methanol washing tower 6 is connected to the gas-liquid separation tank 3. After the methyl tertiary butyl ether raw material is refined by the refining tower 1 (the refining steps are as follows: the methyl tertiary butyl ether raw material is fed from an appropriate tray in the tower, and is separated through continuous vapor-liquid equilibrium, and finally purified The final methyl tert-butyl ether product is discharged from the top of the tower and sent to reactor 2, heavy component impurities are discharged from the tower kettle), and the purified methyl tert-butyl ether is heat exchanged in a heat exchanger (not shown) After that, it enters the reactor 2 (preferably a tubular ...

Embodiment 2

[0086] The other conditions are the same as in Example 1, except that the silica catalyst is used in the cracking reaction and the temperature of the gas-liquid separation tank is adjusted to 60°C.

Embodiment 3

[0088] Except that the oil-water ratio of the water scrubber was adjusted to 1.6:1, other conditions were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com