Self Raman yellow light laser of composite cavity structure

A self-Raman yellow light and laser technology, which is applied in the field of lasers, can solve the problems of multiple components and large insertion loss, and achieve the effects of increasing output power, reducing insertion loss, and high pump power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

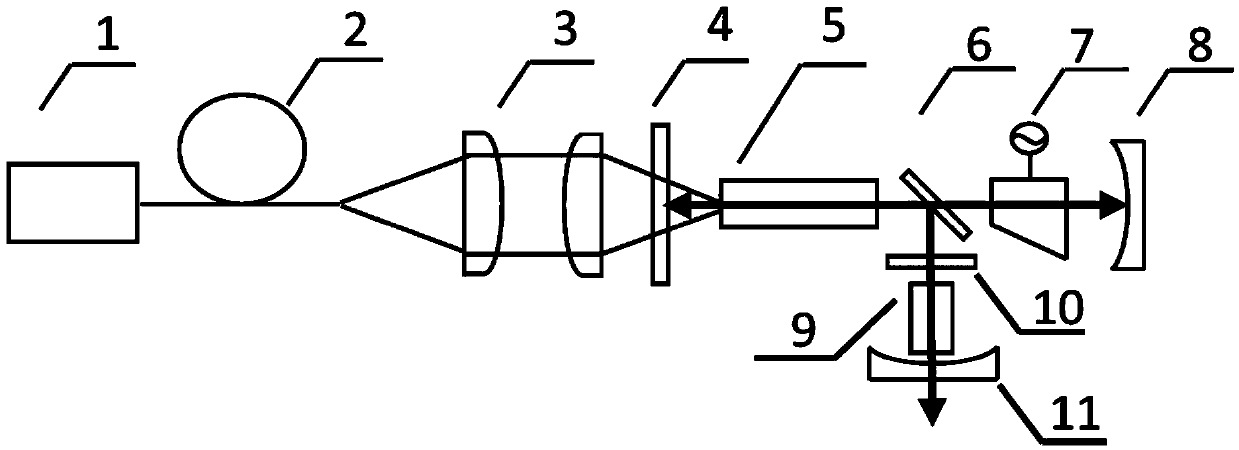

[0022] In order to solve the problem that the pump power of the existing self-Raman yellow laser is limited by the thermal effect and the stable region of the resonator, as well as the problem of multiple components in the Stokes optical resonator and large insertion loss, and improve the performance of the self-Raman yellow laser, An embodiment of the present invention provides a self-Raman yellow laser with a composite cavity structure, see figure 1 , see the following description for details: a self-Raman yellow laser with a composite cavity structure, including: a laser diode pump source 1, an energy transmission fiber 2, a coupling lens group 3, a resonant cavity shared mirror 4, a gain medium 5, and a splitter beam mirror 6, acousto-optic Q switch 7, laser total reflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com