Method for carrying out photocatalytic degradation on sulfamethoxazole

A sulfamethoxazole, catalytic degradation technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as difficult to achieve, and achieve economical and huge social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

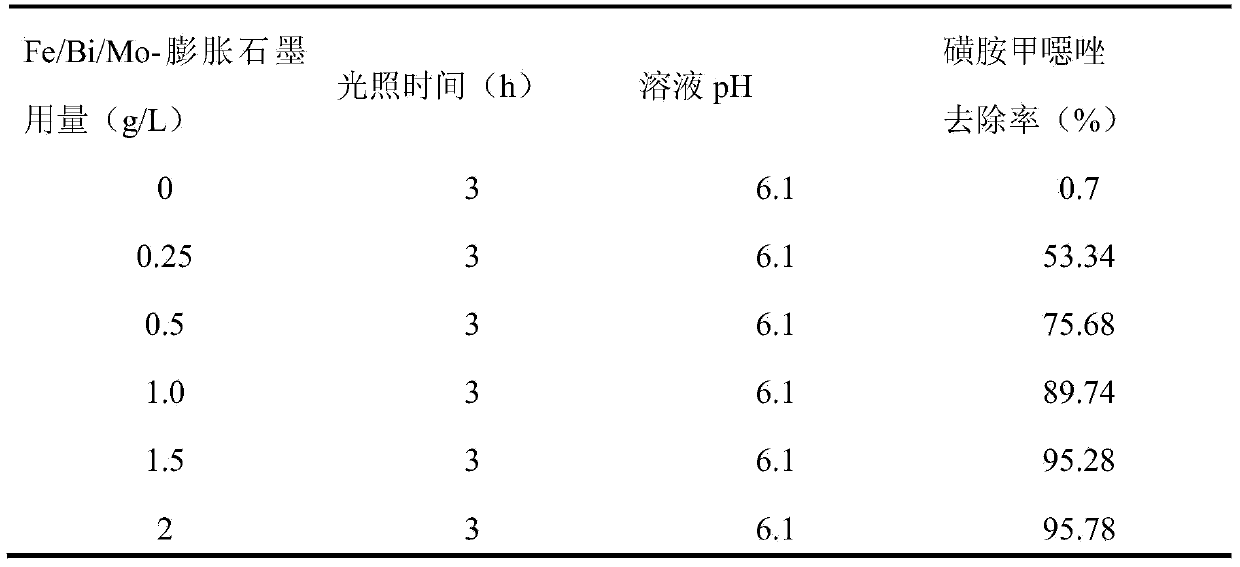

Examples

Embodiment 1

[0014] In the specific implementation, the present invention is realized by the following methods:

[0015] First, prepare Fe / Bi / Mo-expanded graphite composite nanomaterials. The method is to accurately weigh 10g of natural graphite with an electro-optical balance, and put 60mL of concentrated sulfuric acid with a volume concentration of 98% in a 500mL beaker, and place it under ice at less than 4℃. , Slowly add natural graphite to the beaker, stir vigorously for 30 minutes, slowly add 20 g of potassium permanganate and stir for 10 minutes, place the beaker in a constant temperature 30 ℃ shaker for 1 hour, add 100 mL of warm water for dilution. After that, add 30 mL of hydrogen peroxide with a volume concentration of 30% to the above suspension to further oxidize the natural graphite. After reacting for 5 minutes, the graphite oxide is filtered out, and the graphite oxide is washed with 5% dilute hydrochloric acid and 5% dilute potassium bicarbonate by volume. 5 times, fully dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com