Transparent filler masterbatch and preparation method thereof

A filling masterbatch and transparent technology, which is applied in the field of transparent filling masterbatch and its preparation, can solve the problems of low production efficiency, high manufacturing cost, and material leakage, and achieve the effects of improving production efficiency, reducing product cost, and reducing accumulation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

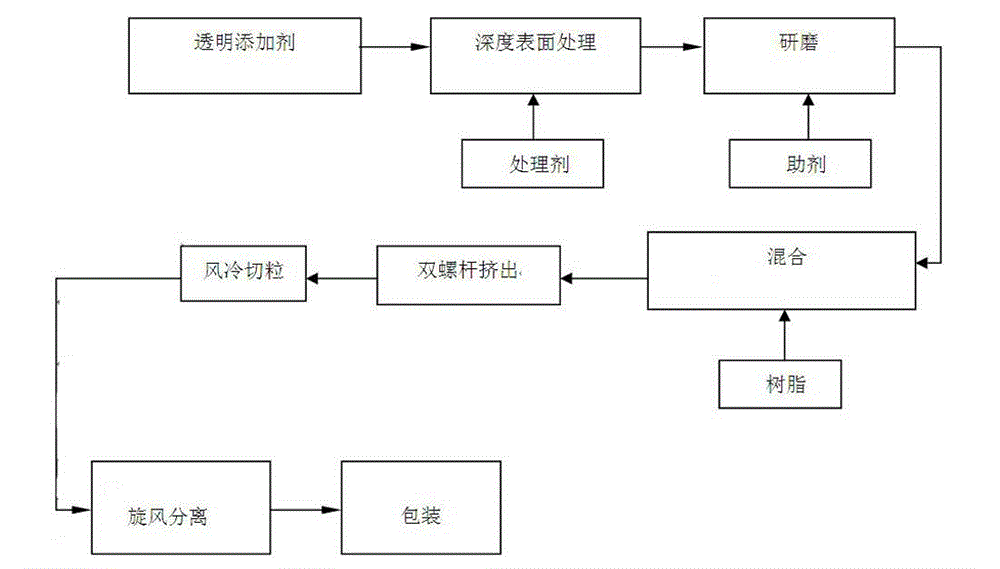

Image

Examples

Embodiment 1

[0021] A formula for transparent filling masterbatch, its composition and weight percentage are: transparent additive content 75%-85%, resin content 10%-20%, processing aid content 3%-6%, surface treatment The dosage is 1%-2%. The processing aid with a content of 3%-6% by weight includes 3%-5% of low molecular weight polyethylene wax, 1%-2% of stearic acid and its salts. The transparent additive is a composite powder of two non-metallic minerals with an average particle size of 2-5 microns; wherein, the composite powder is composed of one or more inorganic minerals containing calcium, aluminum, and silicon elements by weight percentage. 4%-15% of A mineral powder, 85%-95% of B mineral composed of one or several inorganic powders containing boron, magnesium, and barium elements, and 1%-2% of surface treatment. In the embodiment, 5% of A mineral, 94% of B mineral, and 1% of surface treatment are taken, and the surface treatment agent is a coupling agent or stearic acid. The re...

Embodiment 2

[0030] Except for the following features, this example is the same as Example 1: 80 parts of transparent additives, 14 parts of polyethylene, 4 parts of low molecular weight polyethylene wax, 1 part of zinc stearate, 1 part of titanate coupling agent share.

Embodiment 3

[0032] Except for the following features, this embodiment is the same as Embodiment 1: 82 parts of transparent additives, 10 parts of polyethylene, 5 parts of low molecular weight polyethylene wax, 1 part of zinc stearate, 2 parts of titanate coupling agent share.

[0033] Compared with the existing transparent additives barium sulfate, talcum powder and sodium sulfate in the market, the transparent additive in the present invention does not turn white and has a transparent effect close to the natural color of resin. Compared with the conventional masterbatch mixing process, the invention uses a certain feeding sequence and reasonable temperature control to make the pretreated mixture have a smaller bulk volume, make the plasticization more sufficient, the output is larger, and the cost is lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com