Organic electroluminescent device and preparation method

An electroluminescent device and luminescence technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as poor refractive index, low light extraction performance, and loss of total reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

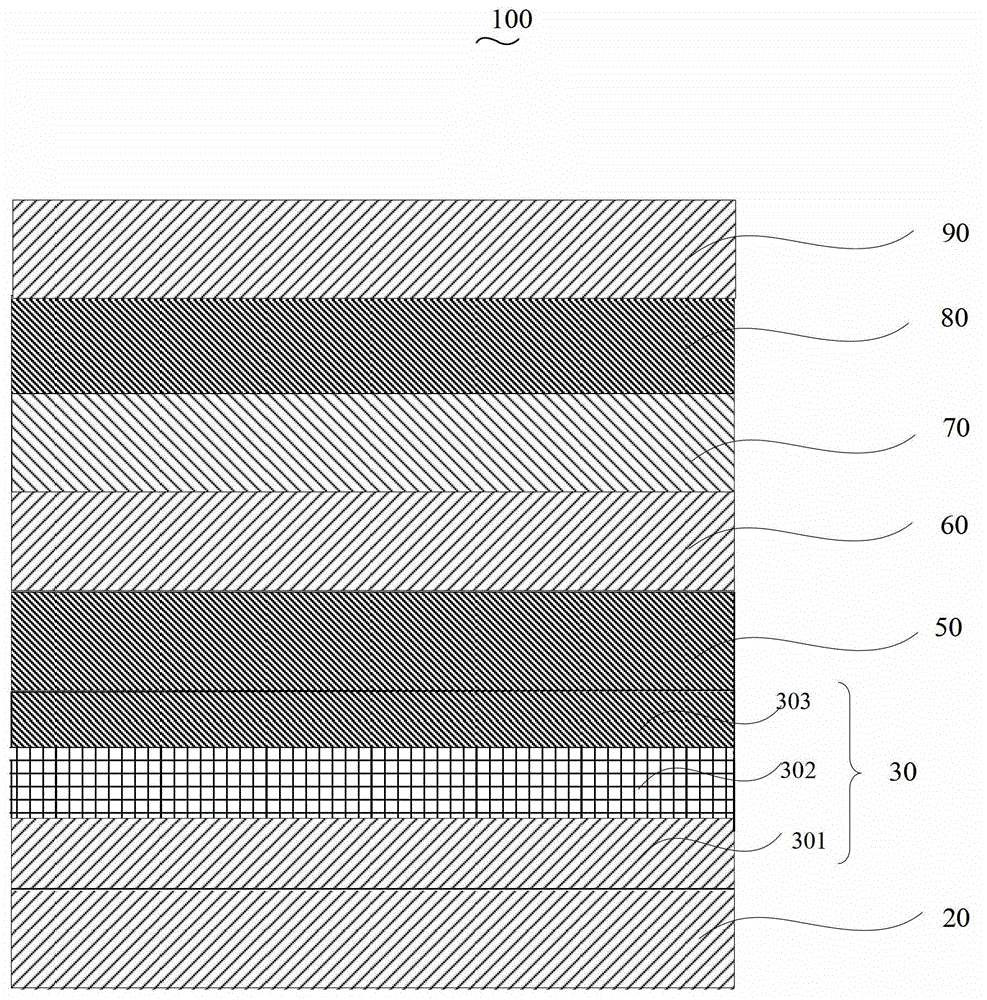

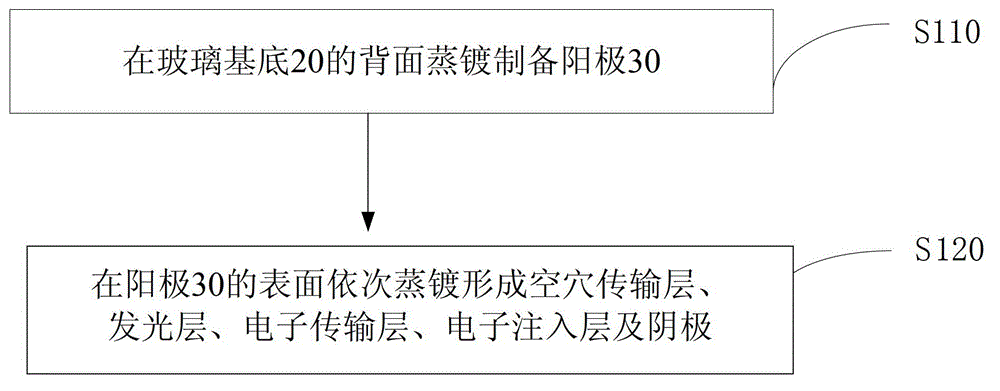

[0033] Please also see figure 2 , the preparation method of the organic electroluminescent device 100 of an embodiment, it comprises the following steps:

[0034] Step S110 , preparing the anode 30 on the back of the glass substrate 20 by vapor deposition.

[0035] The glass substrate 20 is glass with a refractive index of 1.8-2.2, and the transmittance at 400 nm is higher than 90%. The glass substrate 20 is preferably glass with a grade of N-LAF36, N-LASF31A, N-LASF41A or N-LASF44.

[0036] The anode 30 is composed of a first lanthanide oxide layer, a metal layer and a second lanthanide oxide layer stacked in sequence, wherein the first lanthanide oxide and the second lanthanide oxide are selected from praseodymium dioxide, three At least one of praseodymium oxide, ytterbium trioxide and samarium oxide, the metal layer includes a first metal layer and a second metal layer doped in the first metal layer, wherein the first metal layer is selected from At least one of silver...

Embodiment 1

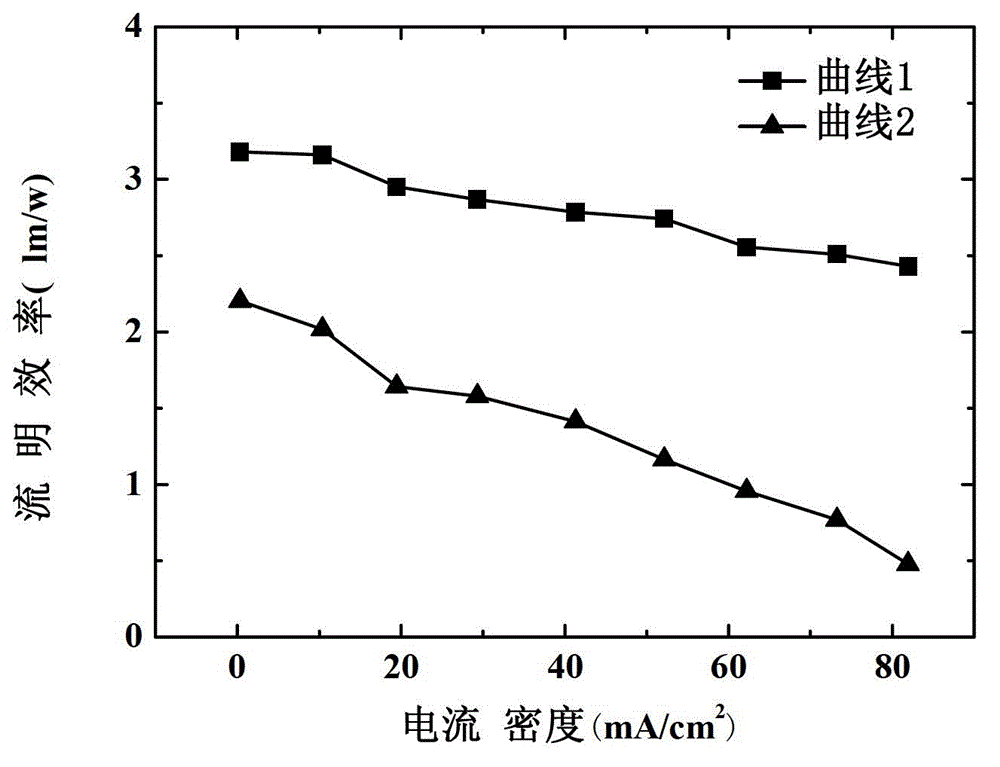

[0050] The structure prepared in this example is / glass substrate / PrO 2 :Mg:Ag:PrO 2 / / TCTA / Alq 3 / TPBi / CsF / Ag organic electroluminescent devices.

[0051] The glass substrate is N-LASF44. After rinsing the glass substrate with distilled water and ethanol, soak it in isopropanol for one night. The anode is prepared on the surface of the glass substrate by evaporation, and a layer of PrO is first evaporated. 2 , with a thickness of 1nm, and then vapor-deposit a metal layer, which is a doped metal layer of Mg and Ag, wherein Mg accounts for 5% by mass of Ag, and the thickness of the metal layer is 10nm, and then vapor-deposits on the surface of the metal layer One layer of PrO 2 , with a thickness of 2nm, and then sequentially evaporated on the surface of the stacked anode to prepare a hole transport layer: the selected material is TCTA, the thickness of the hole transport layer is 45nm, and evaporated to prepare a light-emitting layer: the selected material is Alq 3 , with...

Embodiment 2

[0056] The structure prepared in this example is / glass substrate / Pr 2 o 3 Ca:Al:Yb 2 o 3 / TAPC / ADN / Bphen / LiF / Pt organic electroluminescent devices.

[0057] The glass substrate is N-LAF36. After rinsing the glass substrate with distilled water and ethanol, soak it in isopropanol for one night; prepare an anode on the surface of the glass substrate by evaporation, and first evaporate a layer of Pr 2 o 3 , with a thickness of 2nm, and then vapor-deposit a metal layer, the metal layer is a doped metal layer of Ca and Al, wherein Ca accounts for 1% by mass of Al, and the thickness of the metal layer is 20nm, and then vapor-deposits on the surface of the metal layer Layer Yb 2 o 3 , with a thickness of 2nm, and then sequentially vapor-deposited on the surface of the stacked anode to prepare a hole transport layer: the selected material is TAPC, the thickness of the hole transport layer is 40nm, and the light-emitting layer is prepared by evaporation: the selected material is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Work function | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com